Difference between revisions of "Asphalt Shingles - Valley Intersection with Ridge"

Difference between revisions of "Asphalt Shingles - Valley Intersection with Ridge"

(Created page with "{| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span sty...") |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 7: | Line 7: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

<div style="text-align:center; vertical-align:center"> | <div style="text-align:center; vertical-align:center"> | ||

| − | |||

| − | [[File: | + | {| class="wikitable"; table style="background-color:white"; border="#A9A9A9;" |

| + | |+ Click on any image to expand it | ||

| + | |- | ||

| + | | [[File:ASh 10.5.1-1 CD.jpg | class=img-responsive | link=http://rpm.rcabc.org/images/e/ef/ASh_10.5.1-1_CD.jpg]] || [[File:ASh 10.5.1-2 CD.jpg | class=img-responsive | link=http://rpm.rcabc.org/images/f/fe/ASh_10.5.1-2_CD.jpg]] | ||

| + | |- | ||

| + | | [[File:ASh 10.5.1-3 CD.jpg | class=img-responsive | link=http://rpm.rcabc.org/images/e/ed/ASh_10.5.1-3_CD.jpg]] || [[File:ASh 10.5.1-4 CD.jpg|class=img-responsive | link=http://rpm.rcabc.org/images/b/b5/ASh_10.5.1-4_CD.jpg]] | ||

| + | |} | ||

</div> | </div> | ||

</div><!-- COL-MD-6 --> | </div><!-- COL-MD-6 --> | ||

| Line 15: | Line 20: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | ;(1) [[RoofStar Guarantee Standards for Asphalt | + | ;(1) [[RoofStar Guarantee Standards for Asphalt Shingle Systems#AShVALLEYMEMBRANE|'''Valley Protection Membrane''']]: Applied beneath the metal valley flashing. |

| − | ;( | + | ;(2) [[RoofStar Guarantee Standards for Asphalt Shingle Systems#AShVALLEYMETAL|'''Valley Metal Flashing''']]: Required for open valleys. |

| − | ;( | + | ;(3) [[RoofStar Guarantee Standards for Asphalt Shingle Systems#AShUNDERLAYMENT|'''Underlayment''']]: Required, and installed to overlap the Valley Protection Membrane and the Valley Metal Flashing. Install ‘shingle-style’, following the requirements for side and end laps; use acceptable fasteners, or adhere (if a self-adhering membrane) in keeping with the manufacturer’s published requirements. |

| − | ;( | + | ;(4) [[RoofStar Guarantee Standards for Asphalt Shingle Systems#AShVALLEYTRANSITION|'''Lower Membrane Patch''']]: Required to cover the joint where the ridgeline of one roof joins the sloped plane of another. Cut as illustrated and apply to the slope; the patch must be cut large enough to extend upslope at least 150 mm (6”), but must not exceed the exposure of the ridge cap shingles. |

| − | ;( | + | ;(5) [[RoofStar Guarantee Standards for Asphalt Shingle Systems#AShVALLEYTRANSITION|'''Upper Membrane Patch''']]: Required to overlap the Lower Membrane Patch, ‘shingle-style’, by at least 50 mm (2”). Extend the patch upslope past the Metal Valley Flashing at least 150 mm (6”). |

| − | ;( | + | ;(6) [[RoofStar Guarantee Standards for Asphalt Shingle Systems#AShFIELDAPPLICATION|'''Shingles (field)''']]: |

| − | ;( | + | ;(7) [[RoofStar Guarantee Standards for Asphalt Shingle Systems#AShRIDGE|'''Shingle Ridge Cap''']]: |

| + | ;(8) [[RoofStar Guarantee Standards for Asphalt Shingle Systems#AShVALLEYTRANSITION|'''Split Ridge Cap Shingle Transition''']]: Required to tie the ridge caps into the adjacent roof field shingles. | ||

<hr> | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[RoofStar Guarantee Standards for Asphalt | + | ;(A) [[RoofStar Guarantee Standards for Asphalt Shingle Systems#AShDECK|'''Acceptable Deck''']] |

</div><!-- COL-6-MD --> | </div><!-- COL-6-MD --> | ||

</div><!-- PANEL BODY --> | </div><!-- PANEL BODY --> | ||

| Line 36: | Line 42: | ||

| − | [[RoofStar Guarantee Standards for Asphalt | + | [[RoofStar Guarantee Standards for Asphalt Shingle Systems|<i class="fa fa-chevron-circle-left fa" ></i> RoofStar Guarantee Standards for Asphalt Shingle Systems]] |

| − | [[Asphalt | + | [[Asphalt Shingle Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Asphalt Shingles Construction Details'']] |

[[Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] | [[Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] | ||

Revision as of 17:29, 18 October 2019

| RoofStar Guarantee Standards are blue-linked |

Asphalt Shingle Details

1 WORK INCLUDED

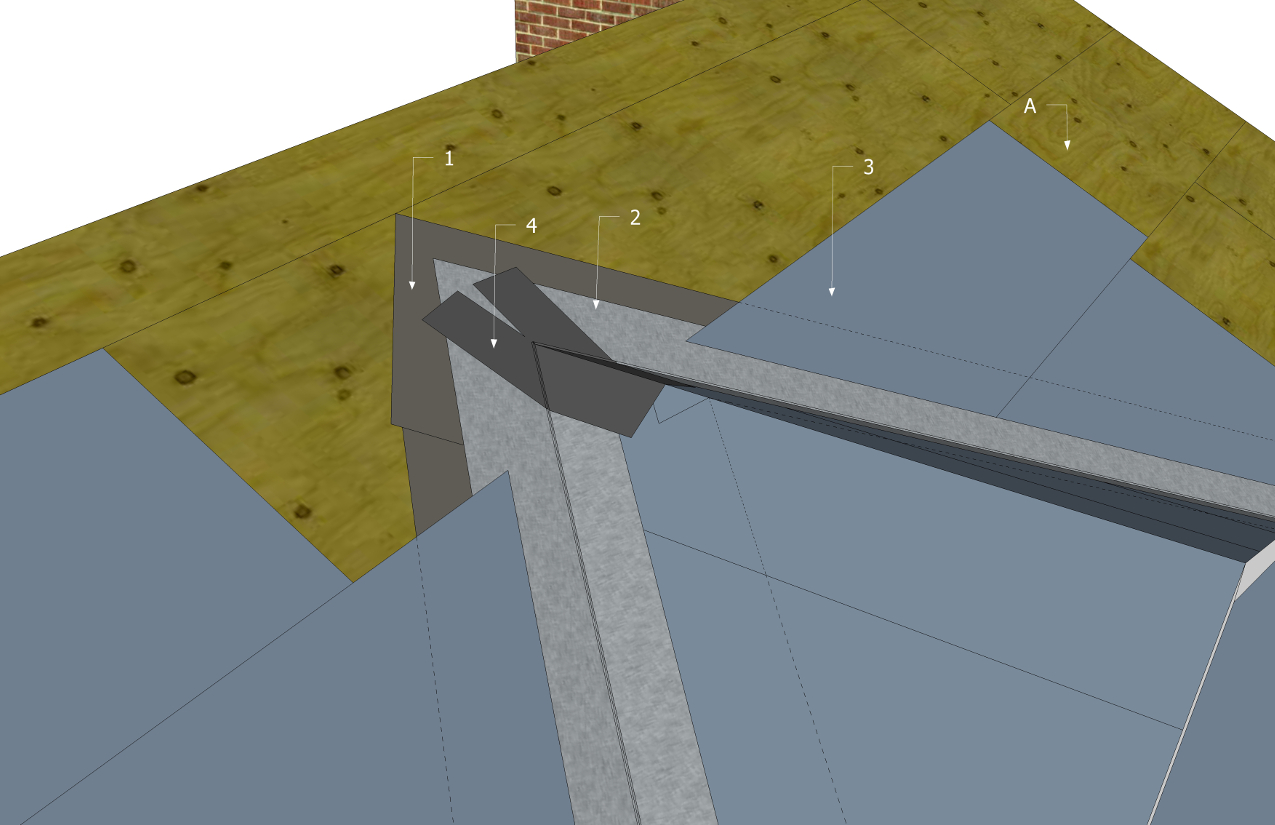

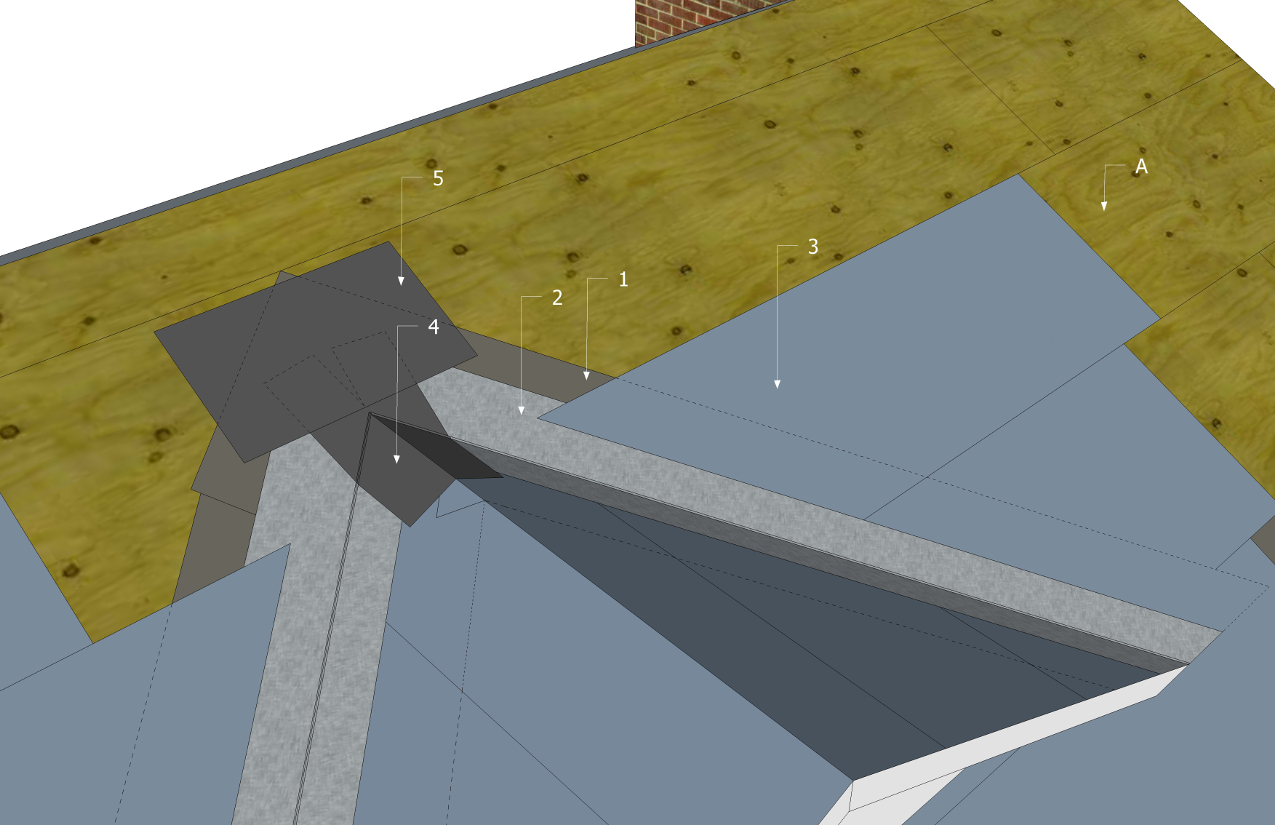

- (1) Valley Protection Membrane

- Applied beneath the metal valley flashing.

- (2) Valley Metal Flashing

- Required for open valleys.

- (3) Underlayment

- Required, and installed to overlap the Valley Protection Membrane and the Valley Metal Flashing. Install ‘shingle-style’, following the requirements for side and end laps; use acceptable fasteners, or adhere (if a self-adhering membrane) in keeping with the manufacturer’s published requirements.

- (4) Lower Membrane Patch

- Required to cover the joint where the ridgeline of one roof joins the sloped plane of another. Cut as illustrated and apply to the slope; the patch must be cut large enough to extend upslope at least 150 mm (6”), but must not exceed the exposure of the ridge cap shingles.

- (5) Upper Membrane Patch

- Required to overlap the Lower Membrane Patch, ‘shingle-style’, by at least 50 mm (2”). Extend the patch upslope past the Metal Valley Flashing at least 150 mm (6”).

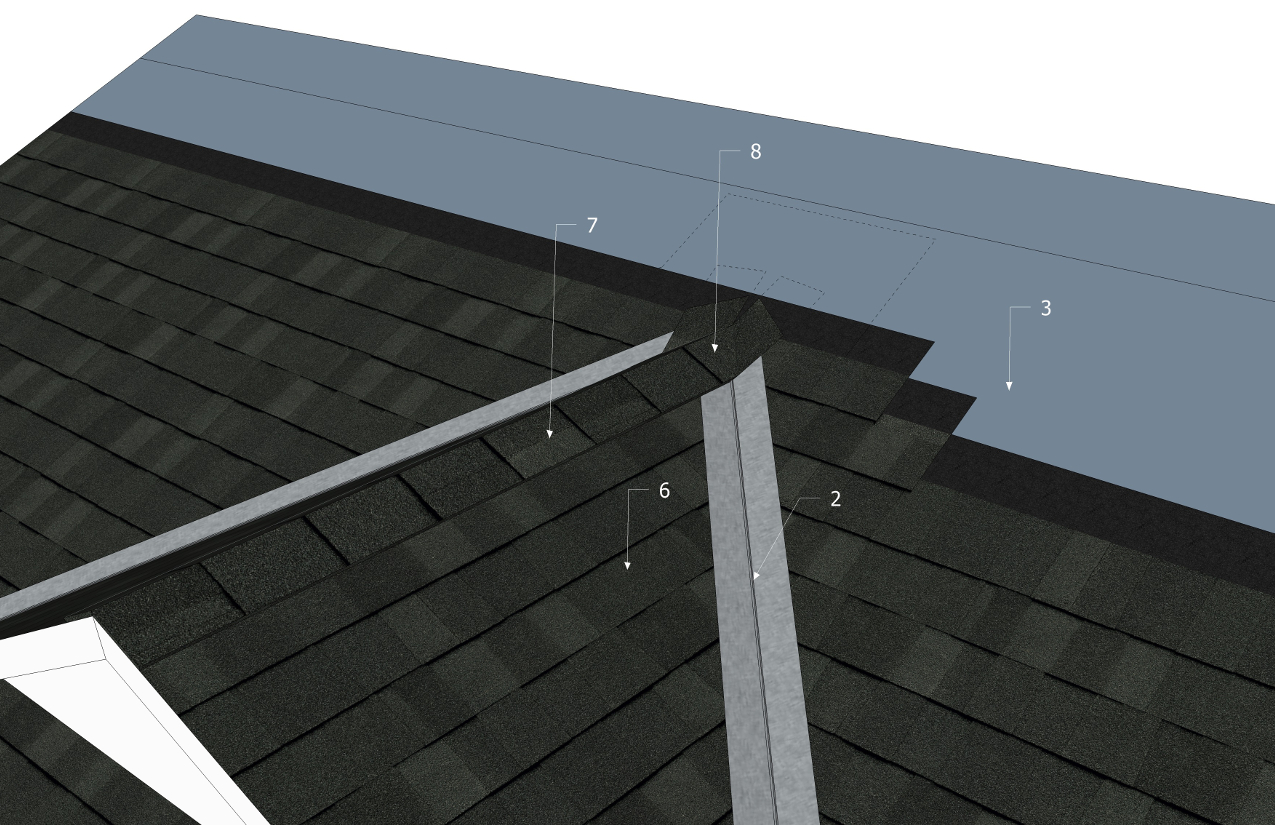

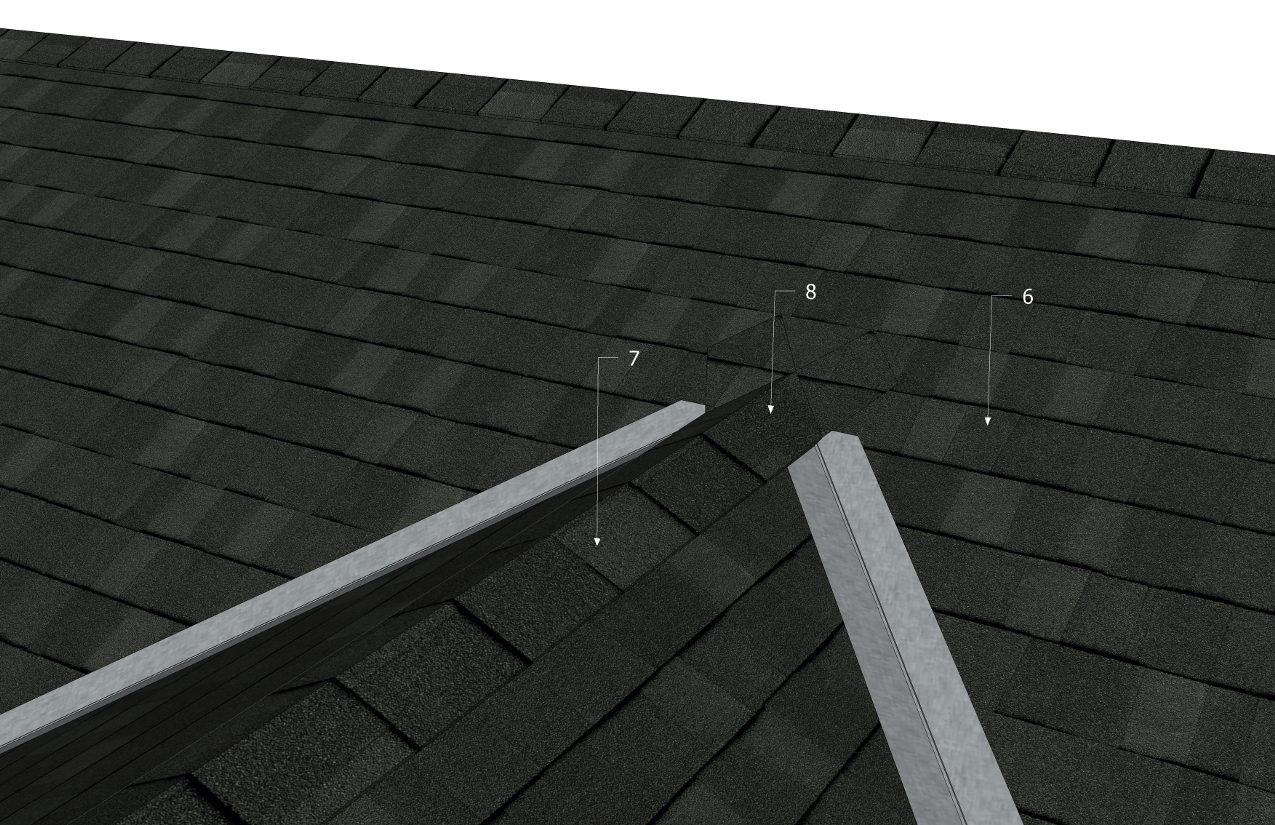

- (6) Shingles (field)

- (7) Shingle Ridge Cap

- (8) Split Ridge Cap Shingle Transition

- Required to tie the ridge caps into the adjacent roof field shingles.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

RoofStar Guarantee Standards for Asphalt Shingle Systems