Category:5.0 Before Delete

Category:5.0 Before Delete

Contents

- 1 D1. SBS (New Version)

- 2 1. Introduction

- 3 2. Definitions and Terminology

- 4 3. RCABC (RoofStar) Guarantee Standards, Policies, Recommendations and Reference Materials for SBS Systems

- 4.1 USING THE TEXT SELECTION BUTTONS

- 4.2 3.1 MATERIALS

- 4.3 3.2 GENERAL

- 4.4 3.3 ROOF DECKS

- 4.5 3.4 VAPOUR RETARDERS

- 4.6 3.5 INSULATION

- 4.7 3.6 INSULATION COVERBOARD

- 4.8 3.7 MEMBRANES

- 4.9 3.8 ROOFTOP GARDENS,PLANTERS & WALKWAYS

- 4.10 3.9 PERIMETER FLASHINGS: MEMBRANES

- 4.11 3.10 PERIMETER FLASHINGS: METAL

- 4.12 3.11 ROOF PENETRATIONS and DRAINS

- 4.13 3.12 OTHER DETAILS

- 5 4. SBS Roof Systems: Accepted Materials

- 5.1 4.1 Vapour Retarders

- 5.2 4.2 Deck Overlay Boards

- 5.3 4.3 Insulation

- 5.3.1 4.3.1 Composite Board Insulation

- 5.3.2 4.3.2 Extruded Expanded Polystyrene Foam (XPS)

- 5.3.3 4.3.3 Expanded Polystyrene Foam (EPS)

- 5.3.4 4.3.4 Polyisocyanurate Foam

- 5.3.5 4.3.5 Fibreboard Roof Insulation

- 5.3.6 4.3.6 Perlitic

- 5.3.7 4.3.7 Mineral Fibre Roof Insulation

- 5.3.8 4.3.8 Lightweight Insulating Concrete

- 5.4 4.4 Insulation Coverboards

- 5.5 4.5 Membranes

- 5.6 4.6 Fasteners

- 6 5. SBS Application and Safety: Best Practices

- 7 6. SBS Master Specifications

- 8 7. SBS Construction Details

1 D1. SBS (New Version)

1.1 Sample of new RPM structure with classes of text)

1.1.1 NOTE: Content has been edited only minimally

2 1. Introduction

SBS-modified roofing membranes, often referred to as "SBS roofing" or simply as "SBS", are relative new-comers to the world of modified bituminous roofing products. SBS-modified roofing membranes comprise a substantial portion of the flexible membrane market, which has largely replaced traditional built-up roofing felts. While offering the higher performance and versatility of a flexible membrane, SBS-modified roofing membranes are also generally compatible with asphalt products, and are therefore useful for re-roofing.

SBS-modified roofing membranes are just one type of modified bituminous roofing. They are flexible membranes manufactured in rolls and are thermoplastic in nature but display variable elastomeric properties, primarily because of the modifiers blended with the bitumen. These membranes are generally manufactured using three materials: (1) modified bitumen, (2) reinforcement fibers, commonly woven as a sheet and embedded within the membrane (these fibers may be glass, polyester, or a blend of the two), and (3) a surface coating, such as stone or ceramic granules. The performance of these membranes (for example, their flexibility or ability to retain their shape under higher temperatures) may be compromised by subtle, seemingly inconsequential changes in composition.

The formulation of the bitumen is critical, particularly when its physical properties are modified by the addition of polymers. Bitumen is most commonly modified with styrene butadiene styrene (SBS) or atactic polypropylene (APP; see separate section in this Manual). The manufacturer must ensure that a suitable degree of compatibility exists between the bitumen and the polymer and that a thorough mix has been obtained. The careful selection and combination of bitumen and polymer (the type of modifier, the percentage of polymer used, etc.) determines the physical properties and long term performance of the modified bituminous “binder” (the meaning of this sentence is unclear; what exactly is the 'binder' and how is it related to the bitumen and polymer used to modify the bitumen? - isn't the "binder" the same as the polymer such as SBS or APP, or is it something else? The structure of this sentence suggests that the polymer and the binder are actually two different things). The binder provides the membrane with its waterproofing capability and may impart the following properties:

- low temperature flexibility

- elasticity

- high temperature resistance to flow

- resistance to aging

The bitumen utilized for oxidized bituminous membranes has been “blown” (clarify), similar to roofing asphalt (see Section 3.9.1). This produces a higher softening point and, therefore, a more useful temperature range. (This means what? That the membrane can be applied using a wider spectrum of temperatures? That it retains its shape under higher temperatures? If so, then let's say that, i.e. "Injecting oxygen into the bitumen results in a higher softening point, which makes installation easier and means the membrane will retain its shape under higher temperatures".)

The physical properties of the binder are further enhanced by applying it to or embedding it in a carrier or reinforcing mat, most commonly a textile such as:

- non-woven spun-bonded polyester

- woven polyester scrim

- fibreglass mats

- woven fibreglass cloth

- combinations of the above

The type of reinforcing selected depends on the end use and desired physical properties of the finished products. The weight, quality, tension during manufacturing, and method of saturation and coating of the reinforcing are some of the factors governing the final product's performance. Some polyester modified membrane manufacturers use oxidized bitumen to saturate the reinforcement, particularly when “heavyweight” material is used.

Membranes are usually surface treated with a parting agent so they do not stick in the roll. Surfaces that will be hot asphalt applied are usually sanded while torch-applied surfaces use polyethylene or other thermofusible films (materials that can be bonded with heat). Exposed surfaces may be embedded with mineral granules (usually ceramic chips or slate flakes) or laminated with metal foil for ultra-violet protection. As an alternative on roofs with minimal slopes, a pour coat and gravel surfacing may be installed over some membranes, although this makes the quality of application difficult to inspect and may lead to problems with membrane slippage due to the weight of the cap sheet and surfacing. (Is this still done? If not, we should remove this information as it is extraneous.)

3 2. Definitions and Terminology

3.1 2.1 COMPOSITION

Bituminous and modified bituminous flexible membrane systems are composite sheet membranes which are thermoplastic in nature but display variable elastomeric properties when modified. These sheets generally consist of bitumen (oxidized or modified), reinforcement, and surfacing materials. The performance of these membranes may be compromised by subtle, seemingly inconsequential changes in composition.

The formulation of the bitumen is critical, particularly when its physical properties are modified by the addition of polymers. Bitumen is most commonly modified with styrene butadiene styrene (SBS) or atactic polypropylene (APP). The manufacturer must ensure that a suitable degree of compatibility exists between the bitumen and the polymer and that a thorough mix has been obtained. The careful selection and combination of bitumen and polymer (the type of modifier, the percentage of polymer used, etc.) determines the physical properties and long term performance of the modified bituminous “binder”. The binder provides the membrane with its waterproofing capability and may impart the following properties:

- low temperature flexibility

- elasticity

- high temperature resistance to flow

- resistance to aging

The bitumen utilized for oxidized bituminous membranes has been “blown”, similar to roofing asphalt (see Section Reference needed). This produces a higher softening point and, therefore, a more useful temperature range.

The physical properties of the binder are further enhanced by the imposition by saturation or coating onto a carrier or reinforcing mat, most commonly a textile such as:

- non-woven spun-bonded polyester

- woven polyester scrim

- fibreglass mats

- woven fibreglass cloth

- combinations of the above

(Some polyester modified membrane manufacturers use oxidized bitumen to saturate the reinforcing, particularly when “heavyweight” reinforcing is used.). The type of reinforcing selected depends on the end use and desired physical properties of the finished products. The weight, quality, tension during manufacturer, and method of saturation and coating of the reinforcing are some of the factors governing the final product's performance.

Membranes are usually surface treated with a parting agent so they do not stick in the roll. Surfaces that will be hot asphalt applied are usually sanded while torch-applied surfaces use polyethylene or other thermofusible films. Exposed surfaces may be embedded with mineral granules (usually ceramic chips or slate flakes) or laminated with metal foil for ultra-violet protection. As an alternative on roofs with minimal slopes, a pour coat and gravel surfacing may be installed over some membranes, although this makes the quality of application difficult to inspect and may lead to problems with membrane slippage due to the weight of the cap sheet and surfacing.

The thickness of the membrane should be suited to the method of application. Torchable membranes must be thick enough to allow the underside to be melted without burning through to the reinforcing and thin enough to be manageable in winter conditions. Hot asphalt applied (mopped) membranes should be of sufficient thickness to perform adequately but should not act as a “heat sink”, lowering the temperature of the asphalt before a sufficient bond is achieved. Manufacturers often refer to membrane thickness in one of two ways. “Nominal Thickness” usually refers to the thickness including any granular finishes. As the granular surfaces do not contribute to the performance of the membrane (except as ultra violet protection and appearance), thickness measured “at the selvage edge” usually gives a more accurate indication of the physical properties of the membrane related to thickness.

3.2 2.2 PERFORMANCE

The physical properties of the membranes available today vary greatly. Each membrane manufacturer “tackles” the problems of roofing technology differently, based on individual design criteria. The design authority, in consultation with the manufacturers, must identify the properties most important for the performance of the roof system on an individual project basis.

As a precaution, RGC has accepted the following performance limitations, based on the lowest expected in-service temperatures of the membrane:

- Temperatures warmer than -10°C (+14°F) require membranes with a minimum tensile strength of 150 N/50 mm.

- Temperatures warmer than -18°C (0°F) up to -10°C (+14°F) require a base sheet or cap sheet with a minimum tensile strength of 294 N/50 mm (CGSB 37-GP-56M Grade 1).

- Temperatures colder than -18°C (0°F) require a base sheet or cap sheet with a minimum tensile strength of 785 N/50 mm (CGSB 37-GP-56M Grade 2).

The design of a roof membrane system is contingent upon many factors and is not solely a function of design temperatures. Consult the membrane manufacturer for assistance with design considerations and membrane selection.

RIDGING & WRINKLING OF MODIFIED BITUMEN MEMBRANES ==

Reprint of CRCA Technical Bulletin, Volume 43, published October 1995:

Can roofs be “perfectly” constructed Under most circumstances, the answer to that question would be ‘No’. Minor aesthetic imperfections, that have no bearing on performance, will always develop due to the materials used and the conditions under which they are installed.

Modified bitumen membranes, with their relatively thin protective surfacing (primarily ceramic granules or metal foils), can be particularly susceptible to the occurrence of these blemishes. Unlike traditional built-up roofs, these membranes are not “hidden from view” by a heavy top pour of asphalt and gravel. The reflective properties of their protective surfacing will allow many minor anomalies, such as deck or insulation unevenness, to readily telescope through to the roof surface. Over time, due to natural weathering and aging, these aesthetic imperfections will become increasingly visible. There are, however, distinct benefits to this aspect of modified bitumen membranes. Some manufacturing defects, such as poor surfacing embedment and uneven or insufficient backside coating, may be detected through an inspection of the rolls prior to installation. Serious errors in application will be apparent almost immediately allowing timely remedial action to take place.

The decision to repair a modified bitumen roof should, as with every type of roofing system, be made only after careful thought and should be based primarily on performance consequences. Open seams, fishmouths at laps, large unbonded areas of the membrane and areas where overheating has resulted in distortion to the reinforcing should be corrected as soon as possible. Trivial anomalies, on the other hand, such as minor wrinkling and ridging are to be expected as a function of the physical characteristics of these materials and their required application methods. Patching a minor blister or a small wrinkle because of visual impact alone is not justified and, in most cases, the repairs will look far worse than the blemish they were intended to correct.

As contractors have become more experienced with modified bitumen membrane installation, application techniques have evolved that have proven to reduce the occurrence and severity of these “blemishes”. These techniques, however, will not eliminate these minor anomalies entirely. In addition, it should be realized that they may significantly increase the cost of a roofing project due to added labour costs and lengthened construction schedules, with only marginal benefits for the owner and no meaningful increase in performance value.

Modified bitumen membranes have proven to provide satisfactory performance in most regions of our country. As with any product, however, they have their limitations. One should not forget that their primary purpose is to be a barrier to moisture. Although they are available in a variety of coloured surfaces and textures, their inherent physical properties make an absolute flawless appearance impossible under most circumstances. A reasonable level of expectation is required by those who specify these membranes together with a reasonable level of care and skill in their application.

4 3. RCABC (RoofStar) Guarantee Standards, Policies, Recommendations and Reference Materials for SBS Systems

<jstbutton group="Guarantee Standards">Guarantee Standards</jstbutton><jstbutton group="policies">Policies</jstbutton> <jstbutton group="rec">Recommendations</jstbutton> <jstbutton group="ref">Reference</jstbutton>

4.1 USING THE TEXT SELECTION BUTTONS

Section C contains materials that have been classified as Guarantee Standards, Policies, Recommendations or Reference (Information). Hide or reveal the classifications as desired, by clicking the buttons above. Guarantee Standards remain visible at all times, in black, and cannot be hidden.

4.2 3.1 MATERIALS

Materials to be covered by the Guarantee Program must be acceptable to RGC. A listing is published in the RCABC Roofing Practices Manual, Section (Reference needed).

All materials must be protected from weather by properly stacking above ground or roof surface and in factory packaging or other adequate covering until applied. All installed roofing materials that are susceptible to moisture damage must be made watertight by the end of each work day.

All roofing components must be supplied or accepted by the membrane manufacturer. See manufacturer component listings. (Sections reference here)

4.2.1 SUGGESTED REVISION:

Materials to be covered by the Guarantee Program must be acceptable to RGC. A listing is published in the RCABC Roofing Practices Manual, Section C.

Materials covered by the Guarantee Program

- that are on site but uninstalled must be protected from weather by properly stacking above ground or roof surface and in factory packaging or other adequate covering until applied.

- that are installed, but susceptible to moisture damage, must be made watertight by the end of each work day.

- must be supplied or accepted by the membrane manufacturer.

4.3 3.2 GENERAL

4.3.1 3.2.1 Application

<jstdiv group="ref">As with all flexible membranes, the quality of the installation is critical to the performance of bituminous and modified bituminous membranes. Although some of the application techniques for these membranes can be similar to those employed in built-up roofing, and the materials can be “familiar”, the differences are critical.</jstdiv> <jstdiv group="rec">It is important that the specifications, details, and installation techniques all conform to the membrane manufacturer's requirements.</jstdiv>

<jstdiv group="ref">One of the major concerns when applying these membranes with hot asphalt is to ensure the asphalt remains hot enough to fuse with the binder of the membrane.</jstdiv> The asphalt temperature must conform to the membrane manufacturer's minimum application temperature and minimum +205°C (+400°F) as required by RGC Guarantee Standards. Asphalt should not be mopped more than 1 m (3') preceding the roll as it has been demonstrated that the temperature of mopped asphalt drops sharply once mopped out (see Section 3.9.1.2). <jstdiv group="rec">In addition to asphalt temperature, particular attention should be paid to slope limitations, fastening requirements, type of asphalt, the amount of asphalt used, and membrane flashing requirements when using hot asphalt.</jstdiv> <jstdiv group="ref">Some manufacturers may require “torched” membrane flashings to ensure a proper bond and prevent problems with slippage or asphalt running down the vertical and collecting at the cant. Slippage can also be a problem when an excessive amount of asphalt is used. Only enough asphalt to meet the adhesive requirements is needed. The mopping asphalt has a lower softening point than the bitumen in the membrane and may result in asphalt running and slippage problems.</jstdiv>

<jstdiv group="rec">The major concern when installing “torch-on” membranes is an obvious one: SAFETY. This is discussed in detail in Section 5.0.1 Safety Precautions - Torching. In addition to safety, it is essential that the membrane be fully and evenly bonded to the substrate. As the roll is installed, the roofer must ensure the full width of the roll is melted and the preceding roll's side lap is preheated. A small “wave” or “bead” of melted bitumen in front of the roll usually indicates sufficient heat. Special attention to seams is required.</jstdiv>

<jstdiv group="ref">The polyester fabric used as reinforcing in many thermofusible (“torch on”) membranes is subject to dimensional changes at high temperatures. Care must be exercised by the applicator not to over-torch or over-heat membranes. Membranes must be designed and manufactured specifically for torch applications.</jstdiv><jstdiv group="rec">It is recommended that the cap sheet installation immediately follow base sheet installation in all cases. However, when it may be necessary to delay the installation of the cap sheet due to weather, project scheduling or the like, then the following criteria must be considered:

- ANY delay in the installation of a cap sheet will result in the requirement for a special inspection and thorough cleaning of the base sheet. The inspection is for mechanical damage from traffic or trades and cleaning is necessary to ensure good adhesion; this must be done to the satisfaction of the roofing contractor.

- Sanded base sheets should have a thin squeegee glaze coat of asphalt applied immediately after application of base sheet if any delay for cap installation is anticipated.

- Base sheets which are either sanded, glaze coated or thermofusible can be exposed for up to six months. It must be recognized that an exposed base sheet is vulnerable to mechanical damage and construction dirt. The base sheet should be well protected by carefully placed and maintained protection panels (plywood for example). This protection would be supplied, installed and removed by someone other than the roofing contractor.

Consult manufacturer(s) for specific construction details and specifications.</jstdiv>

4.3.1.1 3.2.1.1 APPLICATION CAUTION

4.3.1.1.1 MODIFIED BITUMEN MEMBRANES IN HOT MOPPED ASPHALT

- The design authority should recognize that the appearance of wrinkling and ridging in modified bitumen cap sheets applied in hot asphalt may be generic to certain manufacturers of this system, and particularly when attempted in cooler temperatures. Although some manufacturers' literature suggests application may take place in temperatures as low as -25°C (-13°F), there are many subsequent limitations, the variables of which may result occasionally in severe wrinkling or ridging of the cap sheet as well as potentially poor adhesion.# RGC recommends that, in order to minimize the potential for wrinkling and ridging, the use of mopped cap sheets not be considered or specified when ambient temperatures (including wind chill) may go below +5°C (+41°F).

- Many factors affect the behaviour of the finished prefabricated sheets including:

- The quality of the binder (waterproofing agent).

- The choice of carrier including suppliers of fibreglass, polyester, or a combination of the two.

- Saturation of the carrier.

- Engineering of the sheet (composition and placement of the components within the sheet).

- Quality control of the manufacturer.

- Expertise of the manufacturer's personnel (including field representation).

- Recommendations as to what is required for a completed system and the recommended application procedure.

- Installation in the field by a competent contractor.

- The designer's role in choosing the product(s) which satisfy each previous item described.

- The wrinkles or ridges are usually considered an aesthetic problem only, but may occasionally result in fishmouthing and intermittent bonding of the cap sheet. Both of these deficiencies affect the performance of the membrane.

- RGC recommends the use of torch applied thermofusible cap sheets in 2-ply modified bitumen systems in all cases, but particularly if roofing must be carried out in cool or cold weather. Appropriate safety precautions regarding torching must be addressed.

- Occasionally some mopped systems, particularly with heavy cap sheets, have exhibited a propensity for membrane slippage, frequently on insulated systems where there is a combination of slope, heavy inter-ply mopping and lack of mechanical fastening (back nailing) of sheets. (See Section 2.1.3, C5.3 for mechanical fastening requirements and slope limitations).

- It is also common for mopped systems to exhibit some asphalt bleed-out at the seams. Minimal or reasonable bleed-out is to be expected and is an aesthetic problem which may be minimized by the embedment of matching granules. Bleed-out which oxidizes and alligators with time does not normally affect the waterproofing efficiency of the roof.

<jstbutton group="Guarantee Standards">Guarantee Standards</jstbutton><jstbutton group="policies">Policies</jstbutton> <jstbutton group="rec">Recommendations</jstbutton> <jstbutton group="ref">Reference</jstbutton>

4.3.1.1.2 APP MODIFIED BITUMEN MEMBRANES

- Cold Weather Application:

- Designers and contractors should recognize that APP modified bitumen membranes can be extremely difficult to work with in colder temperatures, and that even attempting to unroll the material in very cold temperatures may result in cracking of the sheet or other problems.

- Some manufacturers make different grades of material for application at different times of the year. Most manufacturers recommend an application temperature lower limit of approximately 5°C (40°F). DO NOT ATTEMPT to install APP modified bitumen membranes below these recommended temperatures.

4.3.2 3.2.2 Roof Slope

On all reroofs without positive slope to drain and all protected or modified protected membrane roofing, only non-organic felts or membranes may be used.

Positive slope to drain is an absolute requirement for organic felts. All new construction roofs must have positive slope to drain. Definition of roof slope is provided in Section (reference here). Where required, crickets and saddles should be provided to assist drainage.

<jstdiv group="policies">For single-ply roof systems, a minimum slope 1:15 (3/4" in 12")is required. Any roof areas less than 1:15 (3/4" in 12") require 2 ply membrane assemblies.</jstdiv>

<jstdiv group="rec">A minimum slope of 1:50 (l/4" in 12") is strongly recommended, and should provide positive slope to drain [required for a Five (5) or Ten (10) year RoofStar Guarantee for new construction and for organic felt membrane systems when re-reroofing]. Positive slope to drain is attained when no standing water remains on the deck within a reasonable amount of time after rainfall stops during days with conditions that permit evaporation.

Slope can be provided by sloping the deck, or using tapered insulation boards of insulating fill (insulating fill is rarely used in B.C.). A minimum slope of 1:50 (1/4” in 12”) is strongly recommended. The exception is often drain wells that are designed to collect water and provide a flat surface for the installation of roof drains. Therefore standing water may remain in drain wells for a longer period after a rainfall stops.

Crickets and saddles should be employed between drains where the design slope of the roof is less than 1:50 (1/4" in 12"), where the roof deck is uneven and ponding may occur, or simply to assist the movement of water to drains.

In re-roof applications, when utilizing 2 ply modified asphalt membranes, there is no requirement for slope to drain. However, slope is strongly recommended.</jstdiv>

4.3.2.1 SUGGESTED REVISION

All newly constructed roofs must have positive slope to drain.

<jstdiv group="rec">In re-roof applications, when utilizing 2 ply modified asphalt membranes, there is no requirement for slope to drain. However, a minimum slope of 1:50 (l/4" in 12") is strongly recommended for any low-slope roof, and should provide positive slope to drains.</jstdiv>

For single-ply roof systems, a minimum slope 1:15 (3/4" in 12") is required. Any roof areas sloped less than 1:15 (3/4" in 12") require 2 ply membrane assemblies.

<jstdiv group="ref">Positive slope in this Manual means a slope that drains water sufficiently so that no standing water remains on the deck within a reasonable amount of time after rainfall stops, during days with conditions that permit evaporation. A roof is said to have positive slope even if standing water remains in drain wells for a longer period after a rainfall stops; drain wells are designed to collect water and provide a flat surface for the installation of roof drains.

Slope can be provided by sloping the deck, or using tapered insulation boards of insulating fill (insulating fill is rarely used in B.C.).</jstdiv>

<jstdiv group="rec">Crickets and saddles should be employed between drains where the design slope of the roof is less than 1:50 (1/4" in 12"), where the roof deck is uneven and ponding may occur, or simply to assist the movement of water to drains.</jstdiv>

4.3.3 3.2.3 Re-Roofing

<jstdiv group="policies">Re-roofing over existing membrane is only permitted in specific circumstances and only when approved in writing by RGC and the membrane manufacturer.</jstdiv>

4.3.4 3.2.4 Tying Into Existing Roofing

Where a new roof is tied-in to an existing roof, the two areas must be isolated and separated by a curb joint properly attached to the structure and properly flashed. If job conditions do not allow for a curb joint, written permission from RGC to eliminate curb joints must be obtained and a positive water cut-off must be installed to the deck to isolate the existing roof from the new roof.

4.3.5 3.2.5 Wall Sheathing: Perimeter Requirements (EDITED for format and content)

<jstdiv group="policies">Regardless of the substrate to which roof membranes are applied, installation of roof membrane to the surface must be governed by the membrane manufacturer's requirements for that substrate.</jstdiv>

4.3.5.1 GYPSUM SUBSTRATES

Gypsum boards on vertical surfaces must be RGC Accepted overlay boards with water resistant properties.

<jstdiv group="ref">On steel framed walls, it is acceptable to use gypsum overlay boards accepted for the Guarantee Program, provided the gypsum board has a minimum thickness of 12mm (1/2") or fibre-mat reinforced cement boards with a minimum thickness of 9.5 mm (3/8") that conform to ASTM C1325-04.</jstdiv>

<jstdiv group="policies"></jstdiv>

4.3.5.2 DECK SUPPORTED BY WALL

In combustible construction, or where permitted by the Building Code in non-combustible construction, all concrete or masonry parapets or walls which do not provide a smooth, clean, dry surface for membrane adhesion or are to be applied with oxidized asphalt as the adhesive must be sheathed with a minimum 15.9 mm (5/8") treated plywood, or 9.5 mm (3/8") reinforced cement board that conforms to ASTM C1325-04 mechanically attached to the wall. The plywood is to extend either a minimum of 200 mm (8") above membrane surfacing, to the bottom of the reglet, or, if required by the type of membrane, to the full height of the parapet.

4.3.5.3 DECK NOT SUPPORTED BY WALL

Where permitted by the Building Code, all concrete or masonry parapets or walls to which roofing is to be applied must be sheathed with minimum 15.9 mm (5/8") plywood or 9.5 mm (3/8") reinforced cement board that conforms to ASTM C1325-04 solidly attached to the roof deck with adequately treated blocking. Compressible insulation is to be installed between the sheathing and the wall. Coping and / or counter flashing is to be installed. See construction details Sections 10.3.1 and 10.3.3. The plywood is to extend either a minimum of 200 mm (8") above membrane surfacing or, if required by the type of membrane, to the full height of the parapet or wall. This item is supplied and installed by others unless specified otherwise.

4.3.6 3.2.6 Other

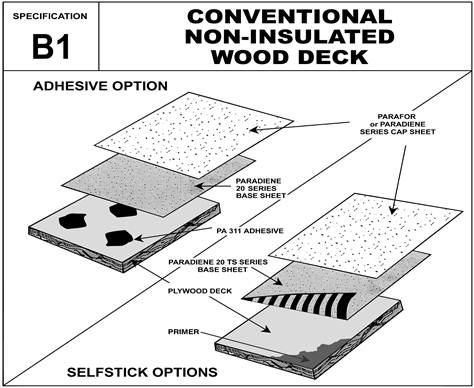

Fully adhering modified bituminous membranes directly to wood decks is not permitted.

<jstbutton group="Guarantee Standards">Guarantee Standards</jstbutton><jstbutton group="policies">Policies</jstbutton> <jstbutton group="rec">Recommendations</jstbutton> <jstbutton group="ref">Reference</jstbutton>

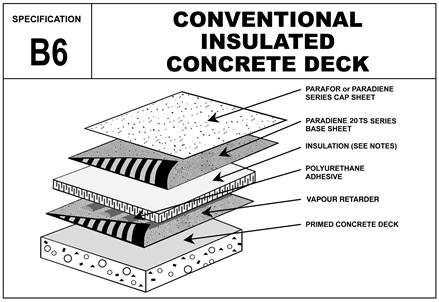

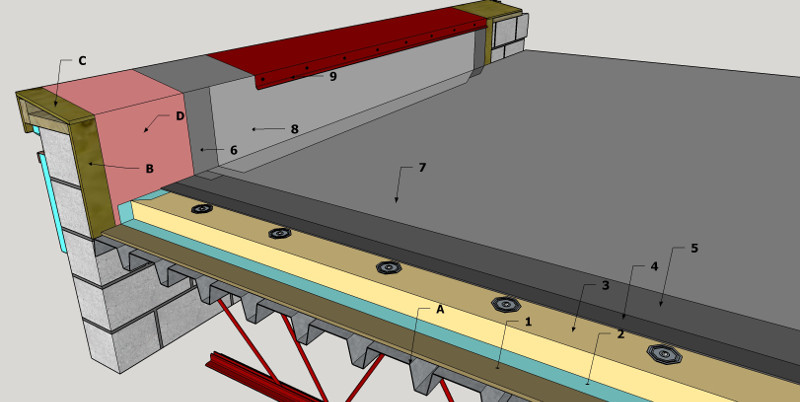

4.4 3.3 ROOF DECKS

4.4.1 3.3.1 Concrete Decks (EDITED for format and content)

- Concrete decks, curbs and equipment pads must be clean, dry, and smooth prior to commencement of roofing.

- Poured concrete or lightweight concrete decks are not to be roofed for a minimum of 28 days after pouring unless expressly instructed in writing by the Project Structural Engineer.

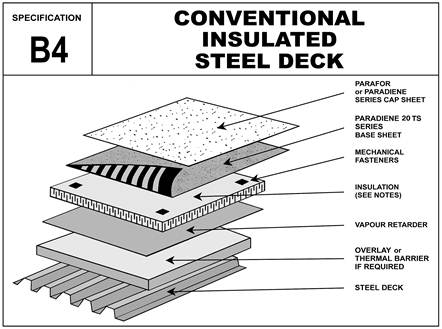

- All concrete decks to receive adhered asphaltic roofing shall be primed.

- A vented base sheet is required under all asphalt-adhered (adhesive, mopped or torched) roofing membranes that are adhered directly to concrete decks unless insulation is installed directly above or over the membrane.

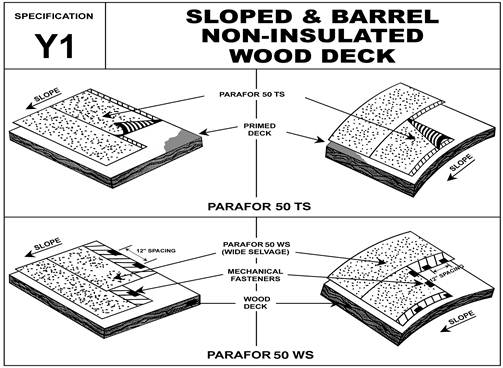

4.4.2 3.3.2 Wood Decks

All wood decks shall be properly fastened to B.C.Building Code requirements. With the exception of standard insulated roof systems, all knots or cracks shall be covered with metal prior to acceptance of deck surface.This work is to be done by others. <jstdiv group="policies">Non-veneer (O.S.B. or wafer board) panels are acceptable sheathing for decks with low-slope roofing applications, provided the roofing membrane is not fully adhered directly to the panels.</jstdiv> The minimum plywood or non-veneer (O.S.B or wafer board) deck thickness for low-slope roofing (i.e., membrane roofing) shall be a minimum 12.7 mm (1/2")and as indicated in the applicable Building Code.

An RGC approved separation sheet, minimum#40 asphalt coated fibre glass base sheet conforming to CAN/ CSA A123.16 - M88 (R1996), Type II or manufacturer’s accepted base sheet of equal or greater weight and reinforcement, or RGC accepted rigid insulation / overlay board mechanically attached or semi-adhered membrane (spot or strips) is required over non-veneer panels before fully adhered roofing membrane is applied.

<jstdiv group="policies">Direct torch (open flame) membrane applications to wood decks and wood surfaces is NOT permitted. For further development of this policy, refer to SBS Application & Safety: Best Practices.</jstdiv>

Differential edge movements or deflection in excess of1/360 of the span in plywood or non-veneer decks in low slope roofing must be prevented by:

- solid blocking under non-supported edges, and /or

- use of tongue-and-groove plywood with non-grooved edges supported by joists or solid blocking, and / or

- when rigid insulation is over the deck, properly sized and installed H-clips must be used on the unsupported edges.

4.4.3 3.3.3 Separation Layers

Pre-cast panels, post-stressed beams, or “T” and cavity decks shall have a separation layer such as fibre board, gypsum board, plywood, proprietary overlay board etc. applied over the deck prior to the application of the roof membrane. Where a difference exists in the levels of adjacent surfaces, the general contractor or others shall install grouting. This grouting shall be feathered on the lower surface a minimum distance of twelve times the amount of the vertical differential.

4.4.4 3.3.4 Electrical Conduit

Conduit, EMT, cable and/or piping applied on the top of roof deck surfaces shall not be acceptable on new construction projects. <jstdiv group="policies">If conduit is present on decks in re-roofing projects, the deck must be made smooth and even to the satisfaction of the accepted roof inspection firm. The upper layer of insulation must cover the conduit, EMT, able and/or piping.</jstdiv>

4.5 3.4 VAPOUR RETARDERS

<jstdiv group="policies">The decision to use and the selection of, a vapour retarder is the responsibility of the design authority. Neither RGC nor the roofing contractor will accept any responsibility for damage to, or failure of, the roof system caused by the use or absence of a vapour retarder.</jstdiv>

4.6 3.5 INSULATION

4.6.1 3.5.1 General

Only RGC Accepted insulations, specifically listed by membrane manufacturers in the RPM as acceptable for use with their modified bituminous loose laid, or mechanically attached base sheets, may be used without an overlay board in the RGC Guarantee Program.

4.6.2 3.5.2 Layering

Multi Layering: All square edge flat format insulation boards greater than 67.5mm (2.7”) in thickness shall be installed in multiple layers. Multi layering of plastic foam insulation is required for all adhered, mechanically attached, and ballasted low slope roof assemblies. In addition, all slope format plastic foam insulation boards greater than 150mm (6”) in thickness shall be installed in multiple staggered layers or alternatively, be installed under two (2)offset/staggered layers of RGC accepted insulation overlay boards.

Insulation board joints are to be offset or staggered 300 mm (12") from adjacent layers and rows.

<jstdiv group="policies">A minus offset tolerance of 50 mm (2") maximum will be permitted to compensate for variance in manufactured tolerance of differing insulation board widths and lengths. The exception is sloped insulation boards that are generally installed soldiered fashion to adjacent rows; and the first layer of overlay board over heat sensitive insulation to facilitate joint taping.</jstdiv>

4.6.3 3.5.3 Nailing Strips

Required on Slopes exceeding 1:12 [1" in 12"]) Where the total insulation thickness on nailable decks exceeds 25 mm (1"), nailing strips shall be mandatory on all insulated exposed membrane roofs utilizing bitumen as an adhesive and / or waterproofing medium (BUR, single or multi-ply modified bitumen or oxidized asphalt sheet systems (mop or torch applied base sheets,non-conventional felts, etc.) and will be supplied and installed by the roofing contractor. These nailers should be nominal 89 mm (3- 1/2") wide and of a thickness equal to that of the primary insulation. Spacing of these nailers will not exceed four feet for horizontal application and two feet for vertical application.Fasteners for attachment of wood nailers shall be two minimum #12 non-corrosive exterior screws spaced a maximum of 400mm (16”) o/c. Attachment screws shall be embedded into support media a minimum of 37.7mm (1.5”) at all nailing strip fastening points. Nailers are to be covered by one layer of accepted overlay board.Fasteners used for attaching membranes to nailing strips(back nailing) shall be membrane manufacturer’s approved screws with plates or nails with a minimum 25 mm(1") head size. Spacing of fasteners or nails on nailing strips shall not exceed 300 mm (12") o/c for horizontal applications and 600 mm (24") o/c for vertical applications.Where deck nailing strips are required to secure roofing nailing or insulation nailing strips (e.g. in concrete decks), deck nailing strips shall be supplied and installed by others.

<jstdiv group="policies">Consult the membrane manufacturer's published data for slope limitations.</jstdiv>

<jstdiv group="ref">Nailing strips are not required for use on RGC accepted in seam mechanically-fastened bituminous or non-bituminous flexible membrane systems. Heat welded or self-adhered SBS modified bituminous systems may be used without nailing strips provided RGC accepted in seam fastener patterns are used throughout all base sheet seams (minimum 24" o/c) and head laps (minimum of 3 fasteners). All layers of insulation are recommended be additionally secured with polyurethane foam adhesive.</jstdiv>

<jstbutton group="Guarantee Standards">Guarantee Standards</jstbutton><jstbutton group="policies">Policies</jstbutton> <jstbutton group="rec">Recommendations</jstbutton> <jstbutton group="ref">Reference</jstbutton>

4.6.4 3.5.4 Mechanical Fastening

When conventionally adhered roof assemblies are installed, (adhered, hot asphalt mopped, torched, etc.), all insulation must be mechanically fastened to all nailable decks including steel, with exceptions as per (reference here). <jstdiv group="ref">The upper layer or overlay in a multiple-layer insulation application does not require mechanical fastening.</jstdiv> The exception is for slopes exceeding 1:12 (1" in 12") or steeper - in those cases, the upper layer must be fastened.

When using multiple layers of plastic foam insulation the layers shall be mechanically fastened, whenever possible, as if they are a single layer. Alternately, when the use of mechanical fasteners is not feasible, or multiple layered assemblies require mechanical fastening of the base layer only, or decks are constructed of non-nailable materials (concrete,) polyurethane foam adhesives may be utilized to adhere insulation layers to one another, to other insulations, or substrates. Only polyurethane foam adhesives that are specifically listed as acceptable by the insulation manufacturer may be used. Extruded polystyrene insulation must have planed faces (removal of smooth surface) when adhered with polyurethane foam adhesive.

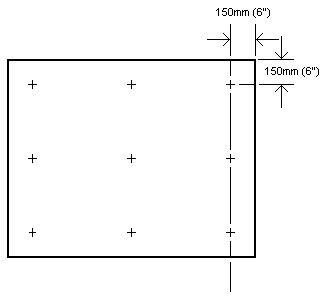

<jstdiv group="ref">The roof area is divided into three areas (zones). The perimeter area is defined as 10% of the building width or 40% of the building height, whichever is less. In no case will perimeter area be less than 2.0 m (7'). The field area is defined as the remaining area after the perimeter is calculated. When the roof height is:• greater than 18 m (60’) and low-slope (slope is 2:12 or less) or• less than 18 m (60’) and pitched (slope is greater than 2:12), Perimeter fastening along the entire eave will be enhanced to corner requirements. The corner area is defined by the perimeter in both directions at the corners.</jstdiv> <jstdiv group="policies">In no case will the corner area be less than 2.0 m x 2.0 m (7’ x7’).</jstdiv>

<jstdiv group="ref">For corner enhancement of roofs in high wind locations (higher than 100 mph) or for roofs above 60’ refer to Section (reference here).

Mechanically attached insulated membrane systems may be fastened according to manufacturer’s tested specifications complying with CSA A123.21-10 or a FM 1-90 assembly wind rating and when accepted by RGC and conforming to A4.6. Factory Mutual adhered assemblies require the initial layer to be mechanically fastened over a steel deck.

The upper layer or overlay in a multiple-layer insulation application does not require mechanical fastening.</jstdiv>

If mechanical fastening to concrete decking is required proprietary concrete fasteners and plates must be used.

Minimum fasteners using Screws and Plastic or Steel Stress Plates: (see Section 3.8.5.2)

| Insulation Board Size | Field | Perimeter | Corner |

|---|---|---|---|

| 600 mm x 1200 mm (2'x4') | 4 | 4 | 5 |

| 600 mm x 2400 mm (2'x8') | 5 | 6 | 8 |

| 900 mm x 1200 mm (3'x4') | 4 | 6 | 7 |

| 1200 mm x 1200 mm (4'x4') | 5 | 6 | 8 |

| 1200 mm x 1800 mm (4'x6') | 6 | 8 | 12 |

| 1200 mm x 2400 mm (4'x8') | 8 | 12 | 15 |

Minimum fasteners using Accepted Nails (Wood Decks Only): (see Section 3.8.5.2)

| Insulation Board Size | Field | Perimeter | Corner |

|---|---|---|---|

| 600 mm x 1200 mm (2'x4') | 5 | 5 | 6 |

| 600 mm x 2400 mm (2'x8') | 8 | 10 | 12 |

| 900 mm x 1200 mm (3'x4') | 6 | 8 | 10 |

| 1200 mm x 1200 mm (4'x4') | 6 | 8 | 10 |

| 1200 mm x 1800 mm (4'x6') | 8 | 10 | 14 |

| 1200 mm x 2400 mm (4'x8') | 12 | 16 | 18 |

Acceptable nail types: Shank-and-head or head-plate nails with minimum 25 mm (1")nominal head size. Head-plate nails with solidly attached plate to ensure plate cannot slide down on shank.

<jstdiv group="ref">Cavity deck or T Deck may be defined as either nailable or non-nailable, depending on profile and deflection.</jstdiv>

Nailing is only permitted on wood decks and where insulation thickness does not exceed 50 mm (2"). Nails with a minimum 25 mm (1") head size or greater are required for insulation and overlay boards fastened to wood decks. Nails to be placed a maximum 600 mm (24") o/c in each direction and be of sufficient length to penetrate the underlying sheathing a minimum of 20 mm (3/4") or in the case of plywood, completely through the sheathing.

When insulation and or cover boards are installed under mechanically fastened membrane systems the membrane manufacturer’s tested and approved fastener layout patterns shall be followed. In addition, the minimum number of fasteners with plates for insulation and or cover boards, under mechanically fastened membranes, shall be six (6) fasteners for 1200mm x 2400mm (4ft. x 8ft,) board sizes and four (4) fasteners for all other smaller board sizes.

For all adhered asphaltic membranes, ie: hot asphalt, torch welded, or cold adhesive applied roof assemblies: Heat Sensitive Insulation: On all heat sensitive insulations (polystyrene; extruded and expanded), an overlay consisting of two layers of acceptable cover board is to be installed when using hot asphalt as an adhesive, or where the cover board is less than 1/2" in thickness on torch applied assemblies.

Two layer system: Fasten the first layer of cover board, offsetting the joints from those of the insulation. Tape the joints before applying the second layer, offsetting the joints from both layers below. Alternatively, all layers of cover board and insulation may be fastened as a group.

Single layer system: Flame protection under or over the cover board is required. Seal over all board joints and wall transitions with membrane manufacturer's approved self-adhered membrane tape. Alternatively, a full layer of minimum No. 25 asphalt coated fiberglass base sheet conforming to CAN/CSA-A123.16-04 (R2009), Type II or No. 30 non-perforated felt conforming to CSA A123.3-05 (R2010) may be used under the cover board.

Composite board insulations with factory applied base sheets that utilize self-adhering seams for flame protection, are mechanically attached over decks listed by the membrane manufacturer, and specifically accepted by RGC, may be installed as a single layer overlay board over heat sensitive insulations.

Minimum Fasteners for Overlay Boards are: 1200 mm x 2400 mm (4' x 8')

| Using: | Field | Perimeter | Corner |

|---|---|---|---|

| Screws and Plastic or Steel Stress Plates | 8 | 12 | 15 |

| Accepted Nails (Wood Deck Only) | 12 | 16 | 18 |

| Fastener layout patterns and other board dimensions | (See Section 3.8.5.2) | ||

Heat Insensitive Insulation Only In the case of heat insensitive insulations, one layer of acceptable overlay board is required. For hot asphalt applied roof assemblies the insulation is to be mechanically fastened before an acceptable overlay board is fully mopped to the insulation. Alternatively, manufacturers proprietary insulation adhesives may be used to adhere accepted overlay boards to insulations. When hot asphalt or adhesives are not used in a roof assembly accepted insulation and overlay board(s) may, as a group, be mechanically fastened directly to nailable decks including steel.

4.6.5 3.5.5 Application to Steel Decks

When installing insulation or thermal barriers to steel decks, all edges of the first layer of insulation or thermal barrier shall be fully or intermittently supported by the deck. Mechanical fasteners must penetrate steel decks a minimum of 20mm (3/4") and must be located in the top flutes only. The minimum thickness of insulation directly over fluted steel decks shall be a minimum of one-half the nominal flute width. Additionally, the minimum allowable thickness of expanded polystyrene or unfaced glass fibre insulation shall be 38 mm (1-1/2"), and the minimum thickness for extruded polystyrene, faced glass fibre, faced polyisocyanurate, etc. shall be 25 mm (1").(For loose laid ballasted systems, see Section reference needed

4.6.6 3.5.6 Adhering Insulation

When foam plastic insulation is adhered (with hot asphalt or compatible adhesive) in a roof assembly, the insulation board size shall be a maximum 1200 mm (4') in any direction.

Only RGC accepted overlay boards may be installed by the back mop and flop application method over heat sensitive foam plastic insulation boards. Heat insensitive insulation boards, (e.g. Polyisocyanurate) are not permitted to be installed with this method.

Asphalt or paraffin-impregnated coated fibreboard roof insulation, used as an insulation overlay board must be asphalt-coated on the top and bottom surface (minimum coated two-sides) when adhered (in a roof assembly) with hot asphalt or asphaltic based adhesive.

Proprietary adhesive applied insulation/overlay board membrane systems accepted and installed in the RoofStar Guarantee Program shall conform to the CSA A123.21-10 Standard test method for the dynamic wind uplift resistance of adhesive attached membrane roofing systems and/or the Factory Mutual I-90 Listing for adhesive attached assemblies.

The roof system must be as per the complete tested assembly and a calculation for the building wind load requirements using the Wind-RCI calculator or RoofNav as applicable be submitted with project documents.

<jstdiv group="ref">Refer to C5.c for notes on wind uplift resistance - fastener patterns and Factory Mutual requirements.</jstdiv>

<jstbutton group="Guarantee Standards">Guarantee Standards</jstbutton><jstbutton group="policies">Policies</jstbutton> <jstbutton group="rec">Recommendations</jstbutton> <jstbutton group="ref">Reference</jstbutton>

4.6.7 Polyisocyanurate Insulation

Only polyisocyanurate insulation with non-organic facers(e.g. fibreglass) are acceptable for use in the RGC guarantee program. In addition, manufacturers’ product identification labels are required for all Polyisocyanurate insulation packaging and the date of manufacture must be provided on all product labels.

4.7 3.6 INSULATION COVERBOARD

4.7.1 3.6.1 General

RGC accepted insulation overlay boards shall be installed over all plastic foam insulations (EPS, XEPS, Polyisocyanurate) on all adhered low slope roofing systems. When heat sensitive insulations (EPS,XEPS) are used with heat welded membrane seams an accepted overlay board must be installed. Fibreboard shall not be used with flame welded seams.

4.7.2 3.6.2 Layering

Insulation and overlay board joints are to be offset/staggered 300 mm (12") from adjacent layers and rows. The uppermost layer of [insulation or] overlay board directly below membranes shall have joints that are offset/staggered from adjacent layers and rows.

4.7.3 3.6.3 Mechanical Fastening

Possible Wording: Refer to C5.c in this Manual for RoofStar Guarantee requirements for the application of mechanical fasteners, as they pertain to both insulation and overlay board applications.

<jstdiv group="ref">The upper layer or overlay in a multiple-layer insulation application does not require mechanical fastening.</jstdiv>

4.7.4 3.6.4 Using Adhesives

For adhered asphaltic membranes overlay board is required over all insulations.

NOTE: Is the following excerpt relevant to the SBS Section?

Adhered Systems For all adhered asphaltic membranes, ie: hot asphalt, torch welded, or cold adhesive applied roof assemblies: Heat Sensitive Insulation: On all heat sensitive insulations (polystyrene, extruded, and expanded), an overlay consisting of two layers of acceptable cover board is to be used when using hot asphalt as an adhesive, or where the cover board is less than 1/2" in thickness on torch applied assemblies. Two layer system: Back mop and flop first layer of overlay board for hot asphalt adhered systems, or use manufacturers accepted proprietary adhesives per published directions, offsetting the joints from those of the insulation. Then tape joints and install second layer offsetting the joints from those of the insulation. Then tape joints and install second layer offsetting the joints from those of the layer below. Alternatively, the membrane manufacturer's proprietary insulation adhesives may be used to adhere accepted cover boards and insulations. Single layer system: Flame protection over the cover board is required. Install the insulation and cover board with the proprietary accepted adhesive. Seal over all cover board joints and wall transitions with the membrane manufacturer's proprietary self-adhered membrane tape.

Asphalt core overlay boards, [minimum thickness 4.5 mm (3/16") nominal] or insulation and insulation overlay boards specifically designed for torch applications, that are accepted by RGC, mechanically attached with nails with a minimum 25 mm (1") nominal head size placed a minimum of one nail per 0.093 m² (1 sq. ft.) or plates and screws placed a minimum of 0.186 m² (2 sq. ft.). Seal all board joints and wall transitions with membrane manufacturer’s approved self-adhered membrane or tapes.

4.7.5 3.6.5 Joint Taping

Acceptable materials for taping joints, of hot asphalt, and cold adhesive applied roof assemblies on overlay board, insulation, gypsum board, and primed plywood are minimum 150 mm (6") wide No.15 felt, 150 mm (6") wide Fibreglass roof tape, or 150 mm (6") wide sheathing (membrane breather-type to CAN / CGSB 51.32-M77). The only acceptable methods of hot asphalt installation are by back coating with asphalt, or laying with a back-coating machine expressly intended for the purpose.

For taping joints of asphalt core overlay boards, without poly film surfaces, manufacturers purpose made self-adhered modified bituminous tapes are acceptable for use with hot asphalt, torch welded and cold adhesive applied roof assemblies.

<jstbutton group="Guarantee Standards">Guarantee Standards</jstbutton><jstbutton group="policies">Policies</jstbutton> <jstbutton group="rec">Recommendations</jstbutton> <jstbutton group="ref">Reference</jstbutton>

4.8 3.7 MEMBRANES

4.8.1 3.7.1 General

While the roof is being applied, all membrane openings at eaves, walls, vents, etc. must be sealed to prevent moisture from entering roofing or between plies of stripping.

Cold Weather Membrane Applications In cold weather regions, membrane selection must conform to the membrane manufacturer’s recommendations for January in service design temperature.

Membrane Surfacing and Slope Limitations (Modified Bitumen Membranes): Only factory cap sheets are to be used on slopes exceeding 1:24 (1/2" in 12"). Manufacturers published instructions as to application methods, materials, and slope limitations are to be followed. On slopes less than 1:24 (1/2" in 12"), double pour, modified double pour or alternate modified double pour and gravel surfacing may be used (see Guarantee Standards reference needed).

<jstdiv group="ref">NOTE: Fully nailed base sheet and torched cap sheet is considered a single-ply for Guarantee purposes.</jstdiv>

Both the base sheet and cap sheet in 2-Ply modified bituminous systems must be of modified bitumen materials using the same polymer. For example, if the cap sheet is an SBS modified bitumen sheet, then the base sheet must be an SBS modified bitumen sheet. Oxidized asphalt sheets will be considered as underlay only and must not be counted as one of two plies.

Both the base sheet and cap sheet must be installed in a parallel direction (not at 90° to each other). Manufacturer's printed instructions for overlaps are to be followed.

For the application of 2-ply ungranulated membranes; both the cap sheet and base sheet are to be applied separately. Shingle fashion application (i.e., 50% lap) is not acceptable except where membrane back nailing is required.

All modified bitumen base stripping terminating on vertical surfaces must be mechanically fastened.

Single Ply Modified Bitumen Membrane Systems

• Membranes used for a single ply modified bituminous membrane system adhered or mechanically fastened shall be a minimum thickness of 3.5 mm on the selvage edge, with a minimum 150 g / meters squared polyester or equal strength polyester-fibreglass combination reinforcement. . • 2 Torch applied membrane applications require a deck separation sheet of a minimum No. 40 asphalt coated glass base sheet or torchable overlay board. Direct torch application to wood surfaces is not permitted. • At roof slope transitions locations where slopes of less than 1:15 (3/4" in 12") meet steeper slopes a two ply membrane assembly must be carried 900 mm (36") beyond the lower sloped roof transition point.

Membrane Lap Preparation for Modified Bitumen Roof Systems • Granules are to be embedded prior to forming laps on all torch applied modified bituminous cap sheets. • Membrane end lap corners must be cut on a bias (clipped or trimmed on an angle) prior to forming laps on all torch applied modified bituminous membrane roof systems.

4.8.2 3.7.2 Mechanically Attached

On all adhered flexible membrane roof slopes that exceed 1:24 (1/2" in 12"), the manufacturer's published instructions are to be followed regarding mechanical fastening and/or back nailing of sheets, and the size and direction of sheet application to the direction of roof slope.

All mechanically fastened flexible membrane systems installed under RoofStar guarantee shall conform to the CSA A123.21-10 Standard test method for the dynamic wind uplift resistance of mechanically attached membrane roofing systems and/or the Factory Mutual I-90 Listing for mechanically attached assemblies.

Mechanically Attached Base Sheet – Cover wood surfaces with a minimum No. 40 asphalt coated fibreglass base sheet conforming to CAN / CSA – A123.16 – M88 (R1996), Type II or manufacturers’ accepted base sheets of equal or greater weight and reinforcement. Attachment of base sheets shall be a minimum of one nail, with a minimum 25mm (1") nominal head size, per 0.093 m2 (1 sq. ft.), or one plate and screw per 0.186 m2 (2 sq. ft). Lap base sheet end laps minimum 150 mm (6"), mechanically fix laps at 100 mm (4") o/c and seal all corner details with membrane manufacturers’ approved self adhered SBS membrane or tape. Wood surfaces must be “dry mop” dry, no pooling or standing water permitted. Metal base flashing is required on all vertical surfaces, walls, curbs, etc., that are 200 mm (8") or greater in height above the finished roof surface, when the mechanically attached base sheet method is used.

4.8.3 3.7.3 Self-Adhesive

Base and cap sheets of all self-adhered and cold adhesive applied roof systems must be installed in the same work day, phased installation of base and cap sheet membranes is not permitted.

Both the base sheet and cap sheet membrane must be competed in the same work day on all modified bituminous self-adhered systems. Specifications and manufacturers written application instructions must be strictly followed. Phased installation of membranes is not permitted.

Self-adhesive membranes must only be installed when ambient temperature meets or exceeds the manufacturer’s printed product installation temperatures. All self-adhesive field membranes must be fully rolled with a manufacturer’s accepted roller that is a minimum 34.2 kg (75 lbs.) or greater and provides an evenly dispersed weight. All flashing (stripping) membrane must be hand rolled with a membrane manufacturer’s accepted roller.

4.8.4 3.7.4 Cold-applied (Adhered)

As stated earlier, Base and cap sheets of all self-adhered and cold adhesive applied roof systems must be installed in the same work day, phased installation of base and cap sheet membranes is not permitted.

Both the base sheet and cap sheet membrane must be completed in the same work day on all adhesive applied modified bituminous systems. Specifications and manufacturers’ written application instructions must be strictly followed. Phased installation of membranes is not permitted.

<jstdiv group="policies">RGC accepts self-adhered and cold adhesive applied membranes installed over wood surfaces to manufacturers’ product installation specifications.</jstdiv>

Self-adhered membranes must not be installed on contaminated wood surfaces. A minimum 9.5 mm (3/8") nominal thick plywood sheeting (overlay) must be installed over all contaminated wood surface (eg. asphalt) to receive self-adhered membranes.

4.8.5 3.7.5 Protected and Modified Protected Membranes

On all protected and modified protected membrane roofing projects, a filter mat of approved material is to be properly installed between gravel ballast and insulation. The filter mat is required under pre-cast pavers that are used as ballast or walkways.

Insulation, which is bonded or mopped directly to the roof membrane, is not acceptable.

Concrete Ballast, Poured-in-place concrete or concrete topping as ballast or traffic topping is not permitted in the roof guarantee programs (see section 2.1.5 Waterproofing Membrane Systems). Only ballast, which permits easy or reasonable access to the membrane, is acceptable.

<jstdiv group="ref">Examples [of acceptable ballast]: properly sized gravel, concrete pavers, concrete-topped insulation, etc.</jstdiv>

Gravel Ballast: Protected Membrane and Ballasted Membrane (EPDM, TPO, PVC, etc.) Shall be clean, washed, round or crushed stone, falling within the following gradations: 35 mm (1-1/2") - 100 % Passing 25 mm (1") 70 - 100 % Passing 20 mm (3/4") 5 - 20 % Passing 12.5 mm (1/2") 0 - 6 % Passing 5 mm (3/16") 0 - 2 % Passing Any variance to the above must be accepted by the owner or the owner's representative and be confirmed in writing.

Pedestals: Installation of proprietary (purpose-made) pedestals, with integral spacer ribs for uniform spacing of pavers, or an accepted drainage layer designed to provide vertical separation between pre-cast pavers and substrate or other underlying materials, is mandatory. The use of proprietary drainage boards or pea gravel with filter fabric to provide drainage for unit masonry products (bricks, stone, etc.), is required. <jstdiv group="ref">The choice of pedestal or drainage layer type is the responsibility of the design authority. Pedestals / drainage layers provide airflow for drying surfaces and assist in leveling. They should not impede the flow of water or air, and should uniformly distribute the dead load of pavers, and other unit masonry products, as well as predicted live loads.</jstdiv>

<jstbutton group="Guarantee Standards">Guarantee Standards</jstbutton><jstbutton group="policies">Policies</jstbutton> <jstbutton group="rec">Recommendations</jstbutton> <jstbutton group="ref">Reference</jstbutton>

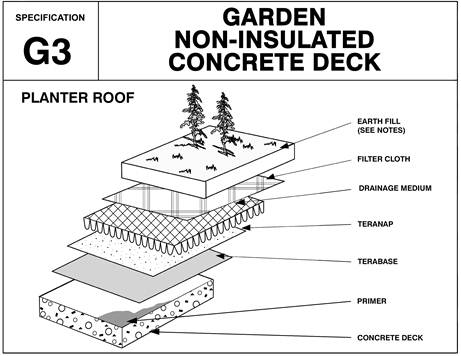

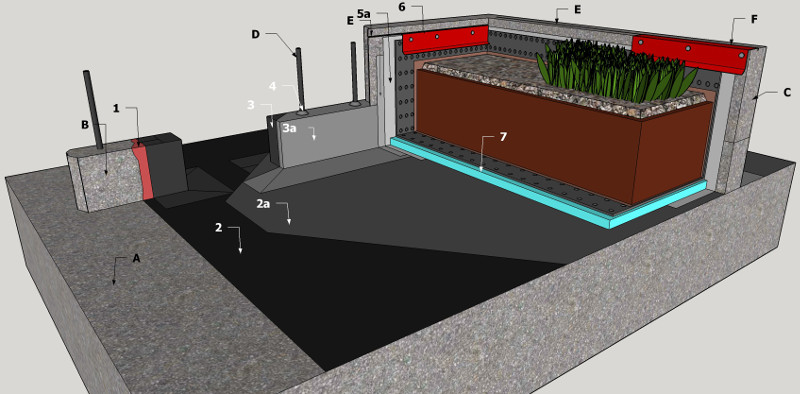

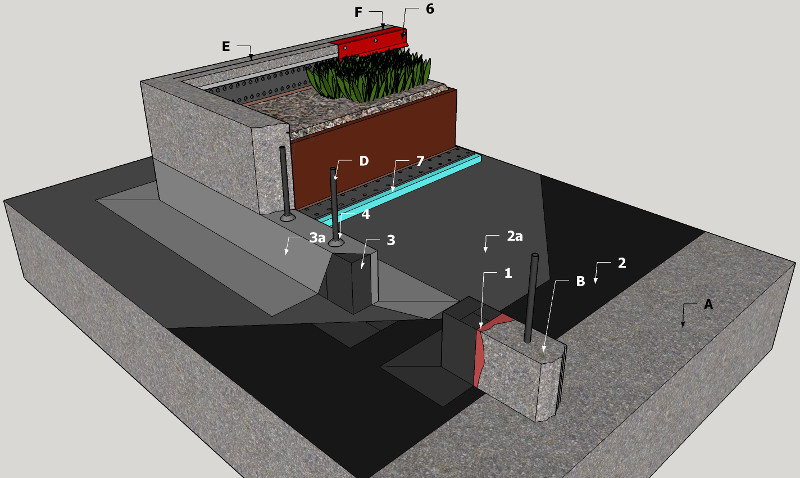

4.9 3.8 ROOFTOP GARDENS,PLANTERS & WALKWAYS

4.9.1 3.8.1 General

SBS Modified Bituminous membranes used on Landscaped and Vegetated roofing systems shall consist of two plies and the top ply (cap) must be a minimum thickness of 3.7 mm on the selvage edge, with a minimum 180g / meters squared polyester or equal strength combination reinforcement. Thermoset and Thermo Plastic (EPDM, TPO, PVC) single ply membranes used for Landscaped and Vegetated roofing systems shall be fully adhered and a minimum thickness of 1.5mm (0.060").

Membrane Protection: Protection for roofing membranes is required during the installation and maintenance of landscaping, extensive and intensive vegetated (green) roofing installations. The minimum membrane protection must be installed by the roofing or waterproofing contractor and shall be 3 mm (1/8") asphalt core protection board or 25 mm (1") minimum extruded polystyrene insulation plus filter mat, root intrusion barrier, and drainage layer. Tightly butt all protection and insulation boards, overlap all filter mat seams and seal all laps of roof intrusion barriers to RGC Guarantee Standards and manufacturer’s installation instructions.

<jstdiv group="policies">Only RGC accepted SBS Modified Bituminous, Thermoset and Thermoplastic roofing membranes that are specifically accepted by the membrane manufacturer for use on Landscaped and Vegetated (green) roof systems qualify for coverage under the RGC Guarantee Program.

The Membrane Manufacturer and RGC must confirm acceptance of other alternative protection systems or components in writing. Damage to membranes and flashings that results from the use of plants with aggressive root structures, (Bamboo, Willow etc.) for landscaped and green (vegetated) roof systems, is specifically not covered under the RGC Guarantee Program or the responsibility of RGC. For additional information refer to the latest addition of the British Columbia Landscape Standard, Green Roof Section.</jstdiv>

4.9.2 3.8.2 Root Barriers & Drainage

Proprietary root intrusion barriers must be acceptable to the roof membrane manufacturer and appropriate for the vegetation system installed. Polyethylene or polypropylene sheeting used as a root barrier shall be a minimum thickness of .2mm (8mils). Root Barriers shall be sheets or boards installed in a continuous plane above the roof membrane, carried up the inside of soil retention perimeters (separation zones), and must be installed with sealed laps and seams as per manufacturer's instructions.

A drainage layer is required. Specialized proprietary drainage products must be acceptable to the membrane manufacturer.

Separation Zones that are free of growing medium and vegetation are required around all roof perimeters, up-stands, drains, penetrations, mechanical equipment, expansion joints, etc. Zones must be a minimum of 300 mm (12”) wide and constructed with curbs or other physical barriers that separate and facilitate drainage. Physical barriers must be placed above the membrane protection layers and must not be attached through or penetrate the roof membrane.

4.9.3 3.8.3 Planter Design & Waterproofing

<jstdiv group="rec">Non-structural planters placed over landscaped deck and roofing membranes, with an appropriate protection layer, are strongly recommended whenever practical.</jstdiv>

4.9.4 3.8.4 Flood Testing

<jstdiv group="policies">Flood Testing is not a recommended practice but is at the discretion of the design authority or owner on systems permitted by ASTM D5957. If flood testing is required, testing shall be conducted prior to installation of overlying insulation or overburdens and conducted as per ASTM D5957.</jstdiv>

4.9.5 3.8.5 Overburdens

<jstdiv group="policies">In the case of Extensive Green Roofs (roof top gardens) with soil thickness of 200 mm (8") or less, when the landscaping (soil and plants) is included as part of the roofing specification and / or contract, the costs for removal and replacement of soil to access the membrane, to investigate or repair leaks in the membrane, are included in the RGC Guarantee coverage. Extensive Green Roofs may be constructed with coarse aggregate or be specialized proprietary drainage panels, vegetation trays and/or mats designed to direct excess water to roof drains. However, the removal and replacement of plants, irrigation lines and or equipment, electrical lines, landscape and decorative features such as concrete pads, statues, planters, large rocks, etc., to investigate or repair leaks in the membrane, is not included, and is the responsibility of others, subsequently such access shall be provided and or paid for by others.

In the case of Intensive Green Roofs (roof top gardens), and Landscaped Roofs with soil thickness in excess of 200 mm (8"), where access to the roofing membrane may be difficult, the removal and replacement of soil and plants to access the membrane to investigate or repair leaks in the membrane is the responsibility of others, and such access shall be paid by others. In addition, the removal and replacement of plants, irrigation lines or equipment, electrical lines, landscape and decorative features such as concrete pads, statues, planters, large rocks, etc., to investigate or repair leaks in the membrane is also the responsibility of others, and such access shall be provided and or paid for by others.

Structural planters that incorporate pre-curb or start-up curbs for walls that are completely sealed with membrane and are a minimum of 100 mm (4") in height, as detailed in Section 5 & 9 Construction Drawings, qualify for RGC Guarantee coverage. Waterproofing liners in planters with structural walls, concrete curb or other materials, that do not incorporate pre-curbs shall be isolated and separated from the guaranteed roofing membrane and are specifically not accepted under the RGC guarantee.</jstdiv>

4.9.6 3.8.6 Walkways and Warning Zones

<jstdiv group="policies">When primary roof membranes of contrasting colour are used for warning zones, membrane end lap off sets and ply side lap directions must be maintained. Staggered membrane end lap offsets may be positioned below primary roof membranes that are used for warning zones.</jstdiv>

<jstdiv group="ref">A design authority or membrane manufacturer may specify a proprietary walkway protection system or warning zone membrane over the primary roof membrane. Walkway and warning zone materials are not part of the roofing membrane assembly but are typically accessory products that are placed over completed roof membranes. Subsequently the type and performance of any walkway or warning zone material is specifically excluded from coverage under the RGC guarantee, as is any detrimental effect the materials may have on the roof system.</jstdiv>

<jstbutton group="Guarantee Standards">Guarantee Standards</jstbutton><jstbutton group="policies">Policies</jstbutton> <jstbutton group="rec">Recommendations</jstbutton> <jstbutton group="ref">Reference</jstbutton>

4.10 3.9 PERIMETER FLASHINGS: MEMBRANES

4.10.1 3.9.1 General

Membrane flashing (stripping) details (with the exception of low parapets, cant strip edges and RGC accepted door sill details) must be designed to provide a minimum 200 mm (8") sealed height above the finished roof surfacing. Surfacing is defined as the top of the roofing assembly, be it membrane, ballast or growing medium (soil). All membrane flashing (stripping) terminating on a vertical surface must be mechanically fastened.

Curbed openings (HVAC, skylights, etc.) must be a minimum height of 200 mm (8") and have at least one ply of membrane flashing (stripping) carried to the inside edge of the curb, or up under the built-in counter-flashing of pre-manufactured metal curbs (i.e. roof scuttles or HVAC) (see Detail Reference here).

Parapet walls may be less than 200 mm (8") in height, but not less than 87.7 mm (3½") in height, refer to RGC Guarantee Standard A6.10.3 (see Details Section 10.3.2).

All cant edge and parapet wall details must have membrane flashing (stripping) that overlaps the exterior finish (i.e. wall cladding) by a minimum of 50 mm (2"). On high parapet walls, that are completely flashed with metal, where membrane flashing (stripping) is terminated part way up the wall the remainder of the parapet must be covered with a flashing underlay of a minimum 40 mils or 1 mm (.040") self-adhered modified bitumen membrane. No. 15 Felt is not acceptable (see Detail Section 10.3.1).

All membrane flashing (stripping) terminating at cladded (i.e. stucco, siding, etc.) walls must lap under the sheathing membrane and cladding by minimum of 75 mm (3").

All membrane flashing (stripping) terminating under a reglet must be sealed to the wall with a compatible mastic (see Detail Section 10.3.3). Where a parapet, cant or separation / expansion joint detail intersects with a higher wall; the membrane flashing (stripping) must be sealed by gussets (membrane saddles) that are formed to protect the inside and outside corners (see Detail Section 10.3.1).

<jstdiv group="policies">New construction projects must follow proper sequencing. Where roof flashings overlap work by others (i.e. siding, stucco, etc.), this work must be complete prior to the installation of metal flashing or wood blocking must be installed to facilitate the future installation of the exterior wall finish under the cap flashing. When lapping under work by others (siding, stucco, etc.), the membrane and metal roof flashings must be installed prior to any wall coverings. Any variance to proper detail sequencing must be approved by the design authority in writing (see Section 10.3.3).

A reverse lap application method for base sheet and base sheet flashing (stripping), at roof up stand transitions, is permitted when self-adhered base sheet flashing is used as flame protection for wood surfaces. Use of the reverse lap method must be an acceptable application method to the membrane manufacturer.

If no published instructions are available, specific instructions in writing from the manufacturer must be obtained and filed with RGC before project start-up.

The roof system must be as per the complete tested assembly and a calculation for the building wind load requirements using the Wind-RCI calculator or Roofnav www.roofnav.comas applicable be submitted with project documents.</jstdiv>

<jstdiv group="ref">There is no minimum height requirement for exterior walls, (e.g. eave drip and gravel stop flashing)</jstdiv>

4.10.2 3.9.2 Cant Strips

Wood: Cant strips are only required as recommended by the membrane manufacturer. The use of hemlock lumber for construction of cant strips and related blocking is not acceptable.

Fibre Cants: Only fibre cants manufactured from non-combustible materials i.e.: perlitic or fire-resistant fibreboard are acceptable for use on roof systems with torch applied membranes.

The self-adhered base sheet must extend a minimum of 150 mm (6") onto the roof surface. The heat welded field membrane must be turned up at the vertical surface a minimum of 100 mm (4") or a heat welded base sheet transition gusset extending 100 mm (4") onto the roof and upstand surfaces be installed.

Membrane gussets must be installed to all inside and outside corners.

Modified Bituminous Base Sheet pre-stripping ply required at all perimeters, upstands and penetrations. Cap sheet stripping is required and must extend 150 mm (6") horizontally and 200 mm (8") vertically from the base of all upstands. All stripping terminating on vertical surfaces must be mechanically fastened.

4.10.3 3.9.3 Expansion and Control Joints

Roof Separation Joints (Expansion and Control Joints, etc.) / Equipment Sleepers / Safety Anchor Piers (poured in place pads) that are completely sealed (enveloped) with membrane flashing (stripping) may be less than 200 mm (8") in height but must not be less than 100 mm (4") in height above the finished roof surface.

Manufacturer’s proprietary roof expansion joint systems are acceptable for use when the systems are located a minimum of 200mm (8") above the finished roof surface and are completely sheathed (covered) with sloped metal flashing.

<jstbutton group="Guarantee Standards">Guarantee Standards</jstbutton><jstbutton group="policies">Policies</jstbutton> <jstbutton group="rec">Recommendations</jstbutton> <jstbutton group="ref">Reference</jstbutton>

4.10.4 3.9.4 Door Openings

Door sill membrane flashing (stripping) may be less than 200 mm (8") in height but must not be less than 100 mm (4") above the primary roof membrane and must be installed to comply with the following conditions:

- A metal water stop flashing, formed with pan folded, welded or soldered corners must be mechanically attached to inside of door sill framing or opening and be sealed with membrane flashing (stripping).

- Membrane flashing, (stripping) or metal pan sill flashing must be installed at doorjamb framing or opening to a minimum height of 100 mm (4") above door sill framing or opening, prior to installation of doorjambs and door sills.

- Membrane gussets must be installed at sill corners.

- Metal pan sill flashings or RGC accepted reinforced liquid flashing systems must be installed wherever clearances preclude the use of membrane flashing (stripping) to seal door sill details.

- Slopes must be provided to direct water away from door sill details. (Overhangs are recommended wherever practical).

- Overflow drains in that area must be installed a minimum 25 mm (1") lower in height than adjacent door sills.

4.10.5 3.9.5 Built-in Membrane Gutters

<jstdiv group="policies">When a built in membrane gutter joins an RGC Guaranteed sloped roof; the gutter will be included by the Guarantee. Built-in membrane gutters that drain a roof not covered by an RGC Guarantee are not eligible for a Guarantee.</jstdiv>

4.11 3.10 PERIMETER FLASHINGS: METAL

4.11.1 3.10.1 General

All roof protrusion and penetration flashings, vents, curbs, sleepers, pipes cable, drains, etc. shall NOT be installed LESS than 200mm (8") from the base of walls, cants, eaves and other roof equipment, protrusion and penetration flashings.

Metal base flashing shall be kept approximately 25 mm (1") above gravel to prevent immersion in water with the exception of protected and modified protected roof systems. (Question: is this relevant to SBS roof systems Standards?).

<jstdiv group="policies">Gravel stop-type flashings may be used, provided manufacturer's printed instructions are followed (see Section reference, if required).</jstdiv><jstdiv group="ref">The exceptions are overflow drains and roof scuppers that are installed through walls. These items are to be located by others.

Sheet metal flashings are designed to divert water away from the membrane flashing termination, usually onto the roof. The metal flashing also protects the membrane from deterioration due to the elements and from mechanical damage. The metal flashing is not a waterproofing membrane, therefore the roofing membrane should be continuous under the metal (see details Section 10.3 and RGC Guarantee Standards for requirements).

Metal flashing is essential to complete most waterproofing and roofing applications and attention to detail is critical. Some basic rules to observe when designing or installing metal flashings are:

- only “S-lock” or “standing seams” are permitted (see Section 10.2.1)

- metal counter flashings always go on top of the completed roof membrane

- limit metal flashing lengths to 3.04 m (10' )

- extend base flashings down over membrane flashing at cants to minimum 25 mm (1") above roof membrane surface. (Not applicable to protected membrane roof assemblies.)

For further details, the Sheet Metal and Air Conditioning Contractors National Association, Inc. (SMACNA) publishes a reliable reference for the proper design and installation of architectural sheet metal. The Architectural Sheet Metal Manual is available from:

Sheet Metal and Air Conditioning Contractors National Association, Inc. c/o British Columbia Sheet Metal Association 156 - 4664 Lougheed Hwy Burnaby, B.C. V5C 5T5 (604) 299-4641</jstdiv>

4.11.2 3.10.2 Material Standards

The following minimum gauges and / or weights of commonly used metals or alloys will be applied to all projects under the Guarantee Program. The length of metal flashing shall be limited to a maximum of 3.04 m (10').

GALVANIZED STEEL: 0.50 mm (0.0196", 26 gauge) galvanized steel sheet, conforming to ASTM A653 / A653M-06 CS Type B, Z275 (G90) coating. Thickness tolerance as per ASTM A924/A924M-06 ±0.08 mm (0.003") for sheet widths not exceeding 1500 mm (60").

ALUMINIUM – ZINC ALLOY COATED STEEL: 0.50 mm (0.0196", 26 gauge) aluminium-zinc alloy coated steel sheet, conforming to ASTM A792/A792M-06 CS Type B, AZM150 (AZ50) coating. Thickness tolerance as per ASTM A924/A924M-06 ±0.08 mm (0.003") for sheet widths not exceeding 1500 mm (60").

ALUMINIUM: 0.80 mm (0.032", 20 gauge) aluminium sheet, utility quality to CSA HA Series - 1975, plain or embossed finish. Maximum thickness tolerance variation ± 0.06 mm (0.0025") based on 1200 mm (48") wide sheet.

STAINLESS STEEL: 0.38 mm (0.014", 28 gauge) stainless steel, Type 302, 304, 316, 2B finish to ASTM A167-82. Maximum thickness tolerance variation ± 0.04 mm (0.0015") based on 1200 mm (48") wide sheet. COPPER: 0.56 mm (0.022", 16 oz.) copper sheet, cold rolled roofing copper to ASTM B370-81. Maximum thickness tolerance variation ± 0.09 mm (0.0035") based on 1200 mm (48") wide sheet.

ZINC: 0.80 mm (0.031") zinc Sheet conforming to European standard EN 988-1996. Maximum thickness tolerance variation ± 0.03 mm (0.0012").