Difference between revisions of "SBS Metal Edge Termination"

Difference between revisions of "SBS Metal Edge Termination"

| Line 22: | Line 22: | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

;(1) Primer: For self-adhered or torch-applied base membranes, as required by the membrane manufacturer. | ;(1) Primer: For self-adhered or torch-applied base membranes, as required by the membrane manufacturer. | ||

| − | ;(2) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems# | + | ;(2) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#MEMB_FIELD_MATERIALS|'''Base Membrane (field)''']]: Torch-applied, adhered, self-adhered (as illustrated), or mechanically attached (subject to deck type and wind uplift design requirements). See Tables '''9.1''' and '''9.2''' for acceptable membrane types and securement options. See '''9.3''' for application requirements. |

| − | ;(3) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems# | + | ;(3) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#MEMB_PERIM_LOW_EDGE|'''Mastic''']]: Applied beneath metal edge flashing. Refer to '''10.3.5.2''' ('''3''')('''2'''). |

| − | ;(4) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems# | + | ;(4) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#LINEAR_M_EDGE|'''Metal Edge Flashing''']]: See '''13.3.2 Fabrication''' for manufacturing requirements. See also '''10.3.5.2 Metal Edge Terminations''' for application standards and securement. Hemmed edges are required; a kicked-out drip edge is optional but recommended (cf. '''13.1.2.2''' ('''10''')). |

| − | ;(5) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems# | + | ;(5) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#MEMB_PERIM_APPLICATION|'''Base Membrane (flashing)''']]: Applied to overlap metal flashing and the field base membrane. |

| − | ;(6) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems# | + | ;(6) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#MEMB_PERIM_APPLICATION|'''Cap Membrane (field)''']]: Installed according to '''Part 9''' standards and sealed along the exposed edge with an un-tooled bead of membrane compatible sealant (cf. '''10.3.5.2''' ('''3''')('''7''')('''2''')). |

<hr> | <hr> | ||

Revision as of 21:20, 13 April 2021

| Notice to Reader | |

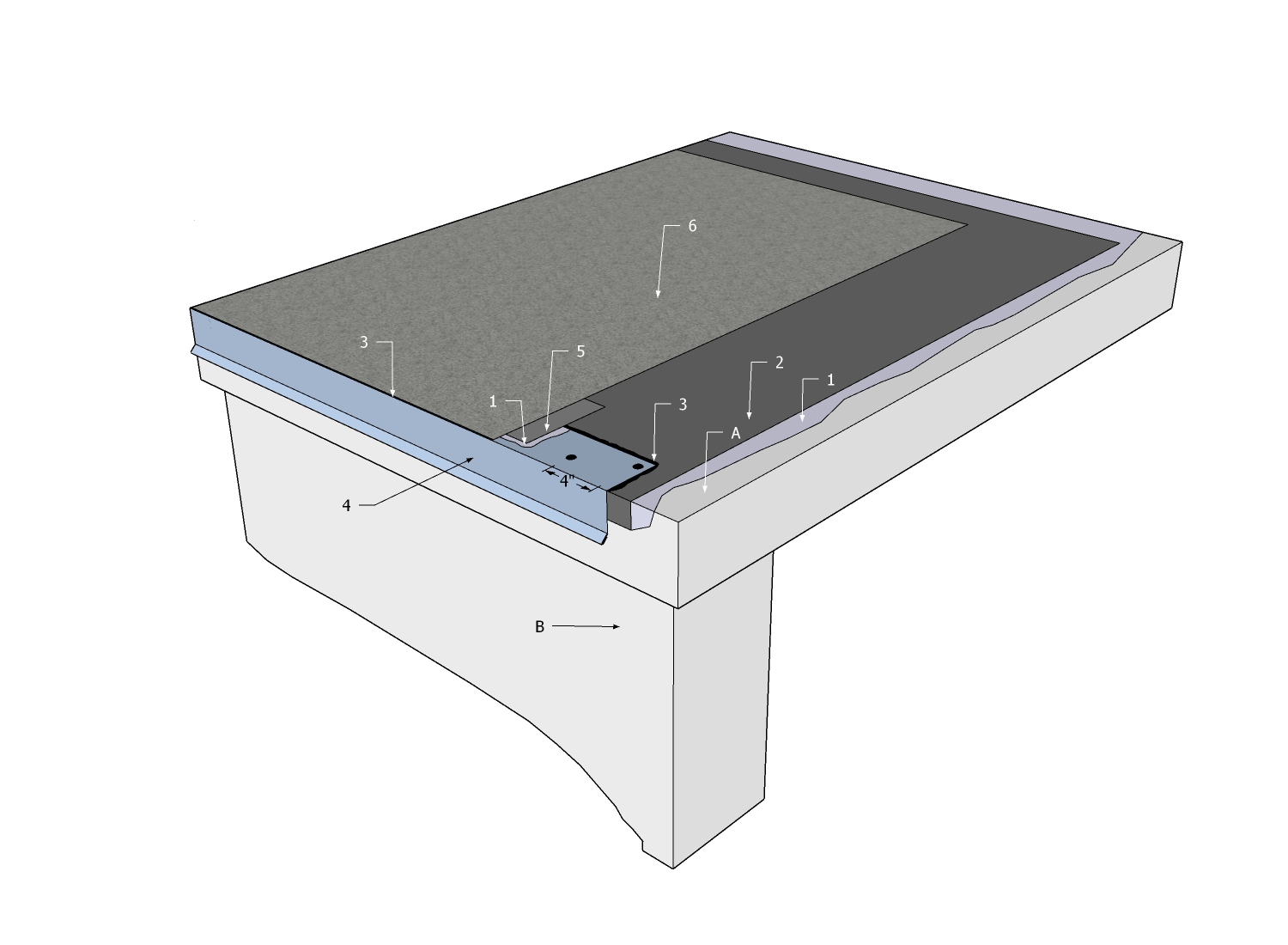

| Images used in a Construction Detail are representative and not intended in their representation of an assembly to be prescriptive. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the Standards, Guiding Principles and Recommendations of the RoofStar Guarantee Standards for a Waterproofing or Water-shedding System. Actual design with respect to dimensions, the selection of materials and their application remains the responsibility of the Design Authority. The full text of applicable RoofStar Guarantee Standards may be read by using the blue hyperlinks | |

SBS Details

1 WORK INCLUDED

- (1) Primer

- For self-adhered or torch-applied base membranes, as required by the membrane manufacturer.

- (2) Base Membrane (field)

- Torch-applied, adhered, self-adhered (as illustrated), or mechanically attached (subject to deck type and wind uplift design requirements). See Tables 9.1 and 9.2 for acceptable membrane types and securement options. See 9.3 for application requirements.

- (3) Mastic

- Applied beneath metal edge flashing. Refer to 10.3.5.2 (3)(2).

- (4) Metal Edge Flashing

- See 13.3.2 Fabrication for manufacturing requirements. See also 10.3.5.2 Metal Edge Terminations for application standards and securement. Hemmed edges are required; a kicked-out drip edge is optional but recommended (cf. 13.1.2.2 (10)).

- (5) Base Membrane (flashing)

- Applied to overlap metal flashing and the field base membrane.

- (6) Cap Membrane (field)

- Installed according to Part 9 standards and sealed along the exposed edge with an un-tooled bead of membrane compatible sealant (cf. 10.3.5.2 (3)(7)(2)).

2 RELATED WORK BY OTHERS

- (A) Acceptable Substrate

- Representative

- (B) Wall Assembly

- Representative

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

Back to RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems