Difference between revisions of "Working Page 3"

Difference between revisions of "Working Page 3"

(→2.1.3.2. Vegetated Roof Systems on Slopes Greater Than 1:6) |

|||

| Line 451: | Line 451: | ||

{| | {| | ||

|- | |- | ||

| − | | colspan=" | + | | colspan="1"; style="text-align:center;width:450px;" | <small>'''Figure 2.1.3.1.'''</small><br><small>Forming Part of Article 2.1.3.1.</small><br><small>(Click to expand)</small> |

|} | |} | ||

</div> | </div> | ||

Revision as of 20:58, 18 July 2024

Contents

- 1 Preface

- 2 Part 1 - General

- 2.1 Section 1.1. Design

- 2.1.1 1.1.1. General

- 2.1.1.1 1.1.1.1. Scope

- 2.1.1.2 1.1.1.2. Coverage and Limitations

- 2.1.1.3 1.1.1.3. References

- 2.1.1.4 1.1.1.4. Defined Terms

- 2.1.1.5 1.1.1.5. Undefined Terms

- 2.1.1.6 1.1.1.6. Objectives

- 2.1.1.7 1.1.1.7. Responsibility for Design

- 2.1.1.8 1.1.1.8. Pre-Design Requirements

- 2.1.1.9 1.1.1.9. Suitability of Design

- 2.1.2 1.1.2. Guarantee Term Requirements

- 2.1.3 1.1.3. All Systems

- 2.1.4 1.1.4. General Design Requirements

- 2.1.1 1.1.1. General

- 2.2 Section 1.2. Reserved

- 2.3 Section 1.3. Application

- 2.1 Section 1.1. Design

- 3 Part 2 – Structural Support and Safety

- 3.1 Section 2.1. Design

- 3.2 Section 2.2. Reserved

- 3.3 Section 2.3. Reserved

Division B - Standards

Vegetated Roof Systems

Standard for Vegetated Roof Assemblies

This Standard is comprised of fourteen (14) Parts that contain the requirements, guiding principles, recommendations, and informative materials necessary for a roof to qualify for a RoofStar 2-year Guarantee for Vegetated Roof Assemblies.

Notes to the Standard are hyperlinked from each Part and can be read by using the link in the Table of Contents for the Standard. Highlighted text within the body of the Standard indicates revisions made within the last twelve (12) months.

This Standard follows a specific structure, incorporates defined terms, and utilizes coloured text to denote specific meaning; this is explained in Division A, Part 2, "Structure and Organization of RPM and Standards". When the requirements in this Standard conflict with other resources found either in this Manual or in instructions published by the vegetated roof system manufacturer, the rules for Authority and Conflict in Division A, Article 2.3.1.2. shall be applied.

Readers are advised to review relevant materials that can be accessed through the hyperlinks embedded in the body of text.

First Edition: June 13, 2024

Previous Edition: N/A

Current Edition: Adopted October 25, 2024

All changes to this Standard are effective

October 25, 2024

© RCABC 2024

No reproduction of this Standard, in whole or in part, is lawful without the expressed permission of the RCABC.

Preface

A vegetated roof assembly (green roof or “living roof”) is a system of materials, together with vegetation, that is built atop a waterproofing roof assembly. Vegetated roof assemblies resist and even transform the effects of weather and sunlight into vibrant life and extended serviceability. They also provide many other significant benefits to a building, its occupants, and those who live and work near it. A key to a well-designed and well-built green roof is an objective, enforceable, recognized standard. When designed and built well, green roofs are enduring enhancements to the buildings they grace.

The Standard for Vegetated Roof Assemblies was developed in collaboration with various members of the RCABC, together with external stakeholders and experts in the field of vegetated (green) roof design, materials, and construction. It covers the essential elements needed to qualify for a RoofStar Guarantee for Vegetated Roof Assemblies and is structured to provide guidance in a linear fashion, from the general to the specific, and from the initial design stage to post-commissioning development and care.

The RoofStar Guarantee for Vegetated Roof Assemblies is unique in North America. Because this Guarantee covers both the waterproofing roof system and the vegetated roof system, the latter must be supplied by the vegetated roof system manufacturer (including materials such as vegetation from their approved suppliers). Some RCABC Affiliate Members manufacture vegetated roof systems and have contractual arrangements with roof system manufacturers to supply a VRS for the waterproofing roof assembly. When that arrangement is substantiated, the RoofStar Guarantee can be extended to cover the Affiliate Member’s system (see Article 1.1.1.4., "Defined Terms", and Article 1.3.2.4., "Contractor Submittals").

While this Standard is focused on the basics of design and constructability of green roofs as rainwater management tools, each design (specifically, those that are classified as semi-intensive or intensive) should aim to balance the limitations of vegetation on a roof with a diversity of plants, and their appropriate support (growing media), to mimic naturally biodiverse habitats.

Like the other RoofStar Guarantees offered by the RCABC Guarantee Corporation, the success of the RoofStar Guarantee for Vegetated Roof Assemblies is predicated on five key policy-driven fundamentals (See Part 3, “Guarantee” in Division A of the Roofing Practices Manual):

- A RoofStar Guarantee attaches only to a roof and vegetated roof system installed and maintained during the Guarantee term by members of the RCABC (including Affiliate Members when they are qualified to install and maintain a green roof).

- Installers and those responsible for maintenance must be trained to a recognized minimum standard, though higher levels of competency are recommended.

- Only vegetated roof systems supplied and warrantied by a vegetated roof system manufacturer qualify as accepted materials (See Article 1.1.1.4., and Article 1.1.3.2.).

- This Standard for Vegetated Roof Assemblies is the only standard by which a green roof may qualify for a RoofStar Guarantee.

- Each RoofStar Guaranteed vegetated roof assembly must be independently reviewed during and after construction to ensure the design, materials, and construction align with this Standard and RCABC policy requirements.

Although this Standard contains numerous best practices for green roofing and covers a broad range of materials, its purpose is to support the RCABC RoofStar Guarantee Program. Readers are advised to consult Part 1 of Division A in the Roofing Practices Manual (RPM) concerning the scope and limitations of this Standard.

This document is not a complete guide to green roofing. It is not a designer’s or consumer’s guide and does not describe the benefits, co-benefits, or limitations of a vegetation-covered roof; an abundance of printed literature and online publications already provide a wealth of information for those who wish to become better informed or educated. Nor does this Standard purport to address all issues that may arise, including matters of worker or visitor safety on the roof. Too many variables, including the myriad of design options, preclude the practicality of such an approach. It is incumbent on the user of this Standard to possesses a level of knowledge, understanding, and competency, in order to make thoughtful, considered choices in the design, construction, and maintenance of a green roof. Although innovative design is encouraged, each design will necessarily be limited by this Standard and may be limited by the availability of systems supplied by vegetated roof system manufacturers. Vegetated roof designs should be responsibly considered, be responsive to the project objectives, focus on performance, and must be designed for maintenance. Within the scope of this Standard, much is possible and permissible. However, not everything permissible is necessarily advisable; good judgement must be exercised at the design stage to ensure a project’s success, and good judgement reaches well beyond what this Standard can address.

As a fully integrated document, every Part of this Standard contains critical requirements that sometimes overlap requirements in other Parts. While numerous requirements are linked internally to related Articles throughout the Standard, not every relationship between requirements is made in this fashion. Therefore, the reader must become familiar with the Standard in its entirety.

Part 1 - General

Section 1.1. Design

1.1.1. General

1.1.1.1. Scope

1) The scope of this Part and the Standard shall be as described in Division A, Part 1. 2) In addition to the Scope described in Division A, this Standard applies to the design and construction of vegetated roof systems that are site-built, or which may be pre-fabricated, in part or in whole.

1.1.1.2. Coverage and Limitations

1) Coverage under the RoofStar Guarantee shall be as described in Division A, Article 3.2.1.2. but excludes 1) death or delayed growth of plants due to planting or seeding schedules specified by the vegetated roof system manufacturer or the designer, 2) maintenance of the design aesthetic of the vegetated roof system, 3) any act or omission by the qualified green roof installer, except as provided for in this Standard, and 4) any impact on the vegetated roof system by future changes to the building, the building occupancy, building use, or nearby development (e.g., shading from new, higher buildings) (See Article 1.1.1.8.).

1.1.1.3. References

1) In this Standard, all references to 1) the "British Columbia Building Code" (the "Building Code", or the "Code"), the Vancouver Building By-law (VBBL), to municipal or regional building codes or regulations, or to other standards, presume the current edition that is in force, 2) materials mean those materials expressly accepted by the Guarantor, unless stated otherwise, and 3) measurements are shown in metric units first, followed by Imperial values (typically in parentheses; see Division A, Article 2.1.3.2., "Measurements"). 2) The following Canadian national, provincial, and municipal standards and guidelines have shaped, or are referenced in, this Standard: 1) CAN/CGSB-4.2 No. 12-2-95, “Textile Test Methods – Tearing Strength – Trapezoid Method” 2) CAN/CGSB-148.1 No. 7.3-92, “Methods of Testing Geotextiles and Geomembranes Grab Tensile Test for Geotextiles”. 3) CAN/CGSB-148.1 No. 4-94, “Methods of Testing Geosynthetics Geotextiles - Normal Water Permeability Under No Compressive Load”. 4) CAN/CGSB-148.1 No. 10-94, “Methods of Testing Geosynthetics Geotextiles – Filtration Opening Size”. 5) Canadian Society of Landscape Architects, “Canadian Landscape Standard”, Second Edition, March 2023. 6) Capital Regional District (City of Victoria), “Stormwater-Green roof Guidelines” (with Appendix A), 2019. 7) CSA-A123.21, “Standard test method for the dynamic wind uplift resistance of membrane-roofing systems”. 8) CSA-A123.24, “Standard test method for wind resistance of vegetated roof assembly”. 9) City of Toronto, “Green roof Construction Standard (Supplementary Guidelines)”, 2010. 10) City of Toronto, “Green Vegetative Roof Building Standard for the City of Toronto”, 2007. 11) CMHC/OAA, “Design Guidelines for Green roofs”, 2006. 12) Green Roofs for Healthy Cities, “Green Roof Design and Installation Resource Manual”, 2013. 13) Metro Vancouver, “Stormwater Source Control Design Guidelines”, 2012. 14) Régie du Bâtiment du Québec (RBQ), “Critères techniques visant la construction de toits végétalisés”, 2015. 3) In addition to Canadian standards and guidelines, this document incorporates methods, tests, and other materials gleaned from the following international resources: 1) AATCC TM195, “Liquid Moisture Management Properties of Textile Fabrics”. 2) ANSI/SPRI Standards 1) ANSI/SPRI RP-14, “Wind Design Standard for Vegetative Roofing Systems”. 2) ANSI/SPRI VF-1, “External Fire Design Standard for Vegetative Roofs”. 3) ANSI/SPRI VR-1, “Procedure for Investigating Resistance to Root or Rhizome Penetration on Vegetative Roofs”. 3) ASTM D570-22, “Standard Test Method for Water Absorption of Plastics”. 4) ASTM D698-12 (2021), “Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3))”. 5) ASTM D4632/4632M – 15a, “Standard Test Method for Grab Breaking Load and Elongation of Geotextiles”. 6) ASTM D4716/D4716M – 20, “Standard Test Method for Determining the (In-plane) Flow Rate per Unite Width and Hydraulic Transmissivity of a Geosynthetic Using a Constant Head”. 7) ASTM D6241 – 14, “Standard Test Method for Static Puncture Strength of Geotextiles and Geotextile-related Products using a 50-mm Probe”. 8) ASTM E2400/E2400M - 06 (Reapproved 2015), “Standard Guide for Selection, Installation, and Maintenance of Plants for Green Roof Systems”. 9) ASTM E2777-20, “Standard Guide for Vegetative (Green) Roof Systems”, which references the following Standards, Practices, Guides, and Specifications, some of which are referenced elsewhere in this Article: 1) ASTM C88, “Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate”. 2) ASTM D1079, “Terminology Relating to Roofing and Waterproofing”. 3) ASTM D1987-22, “Test Method for Biological Clogging of Geotextile or Soil/Geotextile Filters”. 4) ASTM D3786/D3786M, “Test Method for Bursting Strength of Textile Fabrics—Diaphragm Bursting Strength Tester Method”. 5) ASTM D4439, “Standard Terminology of Geosynthetics”. 6) ASTM D4491/D4491M, “Test Method for Water Permeability of Geotextiles by Permittivity”. 7) ASTM D4595, “Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method”. 8) ASTM D4716/D4716M, “Test Method for Determining the (In-plane) Flow Rate per Unit Width and Hydraulic Transmissivity of a Geosynthetic Using a Constant Head”. 9) ASTM D4751, “Test Method for Determining Apparent Opening Size of a Geotextile”. 10) ASTM D4759, “Practice for Determining the Specification Conformance of Geosynthetics”. 11) ASTM D4873, “Guide for Identification, Storage, and Handling of Geosynthetic Rolls and Samples”. 12) ASTM D5199, “Test Method for Measuring the Nominal Thickness of Geotextiles”. 13) ASTM D5261, “Test Method for Measuring Mass per Unit Area of Geotextiles”. 14) ASTM D5262, “Test Method for Evaluating the Unconfined Tension Creep and Creep Rupture Behavior of Geosynthetics”. 15) ASTM D5617, “Test Method for Multi-Axial Tension Test for Geosynthetics”. 16) ASTM D5818, “Practice for Exposure and Retrieval of Samples to Evaluate Installation Damage of Geosynthetics”. 17) ASTM D6637, “Test Method for Determining Tensile Properties of Geogrids by the Single or Multi-Rib Tensile Method”. 18) ASTM D7361, “Test Method for Accelerated Compressive Creep of Geosynthetic Materials Based on Time-Temperature Superposition Using the Stepped Isothermal Method”. 19) ASTM E108, “Test Methods for Fire Tests of Roof Coverings”. 20) ASTM E136, “Test Method for Behavior of Materials in a Vertical Tube Furnace at 750°C”. 21) ASTM E631, “Terminology of Building Constructions”. 22) ASTM E2114, “Terminology for Sustainability Relative to the Performance of Buildings”. 23) ASTM E2396/E2396M-15, “Standard Test Method for Saturated Water Permeability of Granular Drainage Media [Falling-Head Method] for Vegetative (Green) Roof Systems”. 24) ASTM E2397/E2397M – 15, “Standard Practice for Determination of Dead Loads and Live Loads Associated with Vegetative (Green) Roof Systems”. 25) ASTM E2398/E2398M - 15a, “Standard Test Method for Water Capture and Media Retention of Geocomposite Drain Layers for Vegetative (Green) Roof Systems”. 26) ASTM E2399/E2399M – 15, “Standard Test Method for Maximum Media Density for Dead Load Analysis of Vegetative (Green) Roof Systems”. 27) ASTM E2400/E2400M - 06 (Reapproved 2015), “Standard Guide for Selection, Installation, and Maintenance of Plants for Green Roof Systems”. 28) ASTM E2432, “Guide for General Principles of Sustainability Relative to Buildings”. 29) ASTM E2788/E2788M-18, “Standard Specification for Use of Expanded Shale, Clay and Slate (ESCS) as a Mineral Component in the Growing media and the Drainage Layer for Vegetative (Green) Roof Systems”. 30) ASCE/SEI 7, “Minimum Design Loads for Buildings and Other Structures (latest edition). 31) ANSI/SPRI RP-14, “Wind Design Standard for Vegetative Roofing Systems”. 32) ANSI/SPRI VF-1, “External Fire Design Standard for Vegetative Roofs”. 33) CSA-A123.24, “Standard test method for wind resistance of vegetated roof assembly”. 10) European Federation of Green Roof and Wall Association. 11) Landscape Development and Landscaping Research Society e.V. (FLL) (Forschungsgesellschaft Landschaftsentwicklung Landshafstbau e. V.), “Guidelines for the Planning, Construction and Maintenance of Green Roofing”, 2018. 12) National Roofing Contractors Association (NRCA), “Vegetative Roof Systems Manual, Second Edition”, 2009. 4) This Standard also incorporates ideas and best practices adapted from the following publications: 1) Dvorak, Bruce. “Designing and Planting Climate Resilient Green Roofs”, Living Architecture Monitor, Summer 2021. 2) Miller, Roxanne and Nataliia Gerzhova. “Understanding the Behaviour of Fire and Green Roofs”. Living Architecture Monitor, Summer 2021.

1.1.1.4. Defined Terms

1) Words that appear in italics are defined in the Glossary. Where terminology has been adopted from a referenced document (See Article 1.1.1.3.), the terms are not italicized and reader must consult the external resource. 2) In addition to common defined terms used throughout this Standard, the following defined terms are unique to this Standard: 1) Coordinating Registered Professional has the same general meaning as Design Authority but specifically refers to the design professional responsible for complying with all codes and by-laws, as required in the British Columbia Building Code and the Vancouver Building By-Law (Books I and II). 2) Cultivated assembly means a vegetated roof assembly that is cultivated to grow annual or perennial plants intended for cutting and harvesting (e.g., rooftop farms and gardens). 3) Extensive green roof (extensive vegetated system or assembly) means a relatively light-weight green roof that is often inaccessible, is typically shallow (growing media no deeper than 203.2 mm (8”) is comprised of limited plant diversity (often, plant species of the same genus), and requires minimal maintenance (See Note A-1.1.3.2.). 4) Finished roof system surface means the top surface of any roof system, inclusive of ballast or overburden. 5) Green roof (green roofing) has the same meaning as vegetated roof assembly. 6) Green roof design professional (designer) means the person or persons qualified in the work of designing a green roof system, which may mean a landscape architect, a Green Roof Professional, or another professional skilled in the work concerned (See Article 1.1.1.7. and Article 1.1.1.8.). 7) Intensive green roof (intensive vegetated system or assembly) means a heavier green roof that is usually accessible to people, is generally deep (growing media greater than 355.6 mm (14”), supports a very diverse plant profile that may include trees, and requires considerable maintenance (See Note A-1.1.3.2.). 8) Manufacturer means the Associate Member of the RCABC who manufactures the primary roof covering of the supporting roof assembly. 9) Qualified green roof installer means a Contractor or an Affiliate Member of the RCABC that meets the qualification requirements of this Standard (See Article 1.3.2.3.). 10) Qualified green roof project manager means an established employee of the Contractor who meets the qualification requirements of this Standard (See Article 1.3.2.3.). 11) Semi-intensive green roof (semi-intensive vegetated system or assembly) means a mid-weight, moderate height green roof that may be accessible to people, is generally of moderate depth (growing media depth ranging from 152.4 mm (6”) to 355.6 mm (14”), is typified by increased plant diversity, and requires moderate maintenance (See Note A-1.1.3.2.). 12) Single source warranty agreement means an agreement between an RCABC Associate member and an RCABC Affiliate member, in which the Associate member permits the Affiliate member’s vegetated roof system on the Associate member’s primary roof covering without compromising coverage under the RoofStar Guarantee Program. For a single source warranty agreement to be valid, the agreement must be formalized and the signed, dated document shall form part of the Guarantor’s records. 13) Vegetated roof assembly (VRA), used interchangeably in this Standard with “green roof” or “green roofing”, means a functional arrangement of interacting components, inclusive of vegetation, that is designed in conjunction with a roof assembly, is intended to both grow and flourish, and is often installed on a roof to control the rate of rainwater discharged through a storm drainage system. 14) Vegetated roof system means the functional arrangement of green roof components, inclusive of vegetation, apart from the supporting roof assembly. 15) Vegetated roof system manufacturer means an Associate or Affiliate member of the RCABC who manufactures the vegetated roof system (when an Affiliate member of the RCABC is the vegetated roof system manufacturer, there must be a formalized single source warranty agreement with a roof system manufacturer who is an Associate member of the RCABC). 16) Vegetation (plant(s)) means any live plant or portion of a plant (i.e., a cutting or plug), including pre-planted trays, mats, potted plants, and trees or shrubs with wrapped root balls.

1.1.1.5. Undefined Terms

1) The following undefined terms are used throughout this Standard and are not formatted differently from the body of text: 1) The term “primary vegetated roof system” means the vegetated roof system installed directly over the supporting roof assembly, as distinct from the vegetated roof system installed inside planters. 2) The term “bulk material” refers to anything that is usually supplied by volume, as for example growing media or gravel used in separation zones.

1.1.1.6. Objectives

1) Every vegetated roof system shall ensure that it does not adversely affect 1) the structural integrity of the building, 2) the waterproofing integrity of the supporting roof assembly, and 3) the health and vitality of the vegetation. 2) Every vegetated roof system shall conform to the Building Code or By-law having jurisdiction. 3) Every roof system that is part of a vegetated roof assembly shall conform to the applicable Standard in Division B of the RCABC Roofing Practices Manual.

1.1.1.7. Responsibility for Design

1) Each design of a vegetated roof system shall be undertaken by a person or persons qualified in the work concerned (See Note A-1.1.1.7.(2)). 2) The Coordinating Registered Professional is responsible for ensuring the design of the vegetated roof assembly complies with all applicable building, energy, and fire codes having jurisdiction (See Article 1.1.1.9. and Article 2.1.4.3.).

1.1.1.8. Pre-Design Requirements

(See Note A-1.1.1.8.) 1) The Coordinating Registered Professional is responsible to ensure that the vegetated roof assembly design is a multi-disciplinary enterprise that aligns with the designs for structural, plumbing, mechanical, electrical, architectural, building envelope, landscaping, together with all trades whose work intersects with vegetated roofing, to minimize out-of-sequence operations that could compromise the integrity of the green roof (See Article 10.1.3.2., “Sequencing of Operations” and Article 10.3.2.1., “Coordination of Work”). 2) The vegetated roof assembly must be designed to accommodate expected future changes to the roof or its occupancy, as later modifications that directly impact the assembly and the RoofStar Guarantee may significantly alter or even void coverage (See Article 1.1.1.2., “Coverage and Limitations”; see also Article 11.3.2.7., “Removal and Repair”). 3) All vegetated roof assemblies should be designed with or by a professional skilled in the work concerned, using the Critical Path Method.

1.1.1.9. Suitability of Design

(See also Sub-sections 2.1.3. and 2.1.4.) 1) The Design Authority is responsible for determining the appropriate vegetated roof assembly design and must consider (without limitation) 1) the structural capabilities or limitations of the building, 2) fire resistance and the roof class requirements for the building (See Article 2.1.4.3. and Article 7.1.3.1.), 3) local climate, as it has a bearing on 1) exposure to wind loads (uplift and shear, for example), 2) rapid drying conditions (caused, or exacerbated by, wind and extreme heat), 3) frost (including “night sky effect”), 4) available direct and indirect sunlight, and 5) winter freezing cycles, 4) the effects of nearby structures (as these affect exposure to light and weather), 5) reflected heat stress, 6) aesthetics, 7) permissible vegetated roof systems (See Article 1.1.3.2.), 8) the limitations of available water for irrigation (See Article 8.1.3.1.), and 9) maintenance requirements. 2) Details at plane changes of the supporting roof assembly must be capable of handling inter-plane movement, i.e., at deck-to-wall intersections. 3) When the design specifies a semi-intensive or intensive vegetated roof system, any insulation in the supporting roof assembly must possess a minimum compressive strength of 275 kPa (40 psi) but shall in any event utilize insulation and other system materials capable of supporting all anticipated loads (See Article 3.1.3.4. 4) While slope is required for every supporting roof assembly (See Article 2.1.3.1.) structural slope is strongly recommended for protected membrane assemblies (inverted roofs); using tapered insulation to generate slope may negate ELD effectiveness and may affect the dew point of the roof assembly (for more on the dew point in protected roof assemblies, refer to the Article in Division E of the RPM on Protected and Modified Protected Roof Systems).

1.1.2. Guarantee Term Requirements

1.1.2.1. RoofStar 2-year Guarantee for Vegetated Roof Assemblies

1) To qualify for a RoofStar 2-year Guarantee for Vegetated Roof Assemblies, 1) a vegetated roof assembly shall comply with the requirements in this Part, 2) only new materials may be specified for and installed in both the membrane roof assembly and the green roof, 3) the waterproofing roof assembly that supports green roofing shall qualify for a RoofStar Guarantee, and coverage for both the waterproofing roof system and green roof shall commence simultaneously, 4) the green roof shall be concurrently warrantied by the vegetated roof system manufacturer, exclusive of vegetation, for a period of not less than two (2) years from the commencement of the RoofStar Guarantee term, and 5) the Contractor shall furnish to the Guarantor a copy of the maintenance contract with an RGC-qualified maintenance contractor, for the full term of the RoofStar Guarantee.

1.1.3. All Systems

1.1.3.1. Permitted Roof Assemblies

(See Note A-1.1.3.1.) 1) Only roofs with a new membrane qualify for a RoofStar 2-year Guarantee for Vegetated Roof Assemblies, but roofs that have been recovered are not suitable and are therefore not permitted. 2) An extensive green roof may be supported by a 1) fully adhered (AARS) conventionally insulated roof system, 2) a PARS conventionally insulated roof system, but only when screw fasteners are installed in the system below a gypsum-based insulation overlay panel, or 3) protected membrane roof system. 3) Only a protected membrane roof system may be used to support a semi-intensive green roof or intensive green roof, provided the membrane satisfies the requirements in Section 9.1. of the applicable Standard for the supporting roof assembly and is capable of resisting hydrostatic pressure. 4) Roofs with slopes equal to or greater than 1:6 (2” in 12”) must be uninsulated and waterproofed with a membrane acceptable to the Guarantor; a vegetated roof system shall not be installed over water-shedding system, i.e., ASM, asphalt shingles.

1.1.3.2. Permitted Vegetated Roof Systems

(See Note A-1.1.3.2.) 1) To qualify for a RoofStar Guarantee for Vegetated Roof Assemblies a vegetated roof system must be produced, distributed, and warrantied by a vegetated roof system manufacturer and physically supported by a waterproofing (membrane) roof assembly that concurrently qualifies for a RoofStar Guarantee (vegetated roof systems installed on roofs without a RoofStar Guarantee do not qualify for coverage under this Program). 2) A vegetated roof system that qualifies for a RoofStar Guarantee for Vegetated Roof Assemblies may also be installed in structural or non-structural planters so that both are covered by the same Guarantee, provided 1) the vegetated roof system manufacturer will warranty the system in the planters, 2) structural planters conform to the requirements in Part 10 of this Standard and of the Standard for the supporting roof assembly, and 3) non-structural planters are physically attached to or part of the primary vegetated roof system (planters by themselves, or planters that are isolated from the rest of the vegetated roof system, do not qualify for a RoofStar Guarantee). 3) All accepted vegetated roof systems shall, at a minimum, be comprised of a root barrier, a drainage layer, a protection layer, a vapour diffusion membrane, filtration layer, growing media, and vegetation (See Article 5.2.1.2. for root barrier material requirements). 4) A green roof that qualifies for a RoofStar 2-year Guarantee for Vegetated Roof Assemblies Guarantee shall be designed to meet the objectives in Article 1.1.1.6. and shall also 1) preserve life safety of building occupants, including those who access the roof (See Part 2), 2) resist displacement by wind (See Part 3), 3) collect and drain precipitation (See Part 5 and Part 7), 4) suit the roof environment, irrigation needs, and growing media depth (see Note A-1.1.3.2.(1)(9)). Also see Part 1 and Part 9), and 5) promote maintenance of both the vegetated roof system and the waterproofing roof assembly (See Article 1.1.3.3., Part 8, and Part 11). 5) Only extensive vegetated roof systems may be installed over a conventionally insulated roof assembly. 6) Semi-intensive and intensive vegetated roof systems, and systems designed for substantial water detention (so-called “blue-green” roofs), must be installed over an uninsulated or protected membrane roof assembly. 7) Vegetated assemblies designed for walls or slopes greater than 1:1 (12” in 12”) do not qualify for a RoofStar 2-year Guarantee for Vegetated Roof Assemblies (See Article 2.1.3.1.). 8) Rooftop farms and gardens (cultivated assemblies) 1) shall be designed as part of a protected roof assembly, 2) shall be designed with additional protection for the supporting roof assembly (See Article 5.1.3.1.), and 3) are ineligible for coverage applicable to both the growing media and vegetation. 9) An existing vegetated roof system that is renovated may qualify for a RoofStar Guarantee, provided 1) the supporting roof assembly membrane is new and qualifies for a RoofStar Guarantee, 2) all components of the vegetated roof system are new or will be expressly warrantied by the vegetated roof system manufacturer, and 3) the existing growing media is acceptable to the vegetated roof system manufacturer (See Article 7.1.3.1.).

1.1.3.3. Establishment and Maintenance

(See Note A-1.1.3.3.) 1) Every vegetated roof assembly 1) must be designed to achieve a reasonable state of vegetation establishment based on the type of vegetated system, the system’s plant profile, the planting schedule, and supporting irrigation (See Article 11.3.2.1.), 2) must include maintenance plans and procedures for ongoing maintenance after establishment (See Article 11.1.3.2.), and 3) must be designed to provide safe access for maintenance, where the roof is at least 3 m (10’) above the surface of the ground, or where a hazard to a person exists, should a fall be possible (this requirement also applies to roof areas intended for regular occupancy). 2) Intensive and semi-intensive vegetated roof assemblies must be accessible for maintenance directly from a floor or via a staircase; hatch access is permissible only for extensive vegetated roof assemblies. 3) Design elements to mitigate fall hazards should align with the Code having jurisdiction, and with the Workers Compensation Act Regulations, and should include 1) perimeter walls (i.e., parapets) that satisfy minimum Building Code, local by-laws, and WorkSafeBC occupational health and safety requirements for walls used as fall restraint, 2) guardrails, or 3) tie-off anchors. 4) All roofs with a field elevation greater than 6096 mm (20’) above grade must incorporate access to the roof by stairs and a doorway or with a properly located roof hatch. 5) Any hatch, ladder or mechanical unit should be located a sufficient distance away from the roof edge (setback zone) so that other fall protection measures are not required by those using or accessing the roof to service it. 6) When it is not possible to situate a hatch, ladder, or mechanical unit outside the setback zone, guard rails should be designed for the roof edge to provide additional fall protection for those using or accessing such equipment.

1.1.3.4. Electronic Leak Detection

(See Note A-1.1.3.4.) 1) Electronic Leak Detection (ELD), when specified by the Design Authority, shall conform to 1) ASTM D7877, "Standard Guide for Electronic Methods for Detecting and Locating Leaks in Waterproof Membranes", or 2) ASTM D8231, "Standard Practice for the Use of Low Voltage Electronic Scanning System for Detecting and Locating Breaches in Roofing and Waterproofing Membranes." 2) Electronic Leak Detection (ELD) is recommended for all vegetated roof systems but required when they are installed at grade (Ref. RGC Standard for Grade-level Waterproofing Systems). 3) When Electronic Leak Detection is specified, it shall provide detection capabilities for all waterproofed surfaces, and should extend at least 50.8 mm (2") vertically from the drainage plane at 1) all transitions, 2) any point along the entire deck perimeter, and 3) protrusions.

1.1.3.5. Reserved

1.1.3.6. Variances

1) When a design is unable to conform to the Standard, the Design Authority may apply to the RGC for a written Variance. 2) Application for a written Variance must be made in writing (email correspondence is common), and must 1) identify the project name and its civic address, 2) identify the RoofStar Guarantee number (if assigned), 3) identify the Contractor (if awarded), 4) identify the type of RoofStar Guarantee (Vegetated roof system, or Vegetated roof assembly), 5) articulate the nature of the design problem, 6) identify the RoofStar Guarantee requirement to be varied, and state the desired modification (i.e., reduce the requirement for 203.2 mm (8") to 152.4 mm (6")), 7) cite the reference to which the Variance will apply (i.e., Standard name, article number, sentence number, etc.), and 8) provide design drawings, photographs, and roof plans, referencing grid lines that identify or articulate the boundaries to which the Variance will be applied. 3) Variances are issued by the RGC only to the Design Authority and will be distributed to the Contractor. 4) A Variance is valid only if it receives the full written support of the vegetated roof system manufacturer. 5) A Variance may be unrestricted in its scope, or it may include one or more conditions, or a restriction in coverage, that will affect the design and construction of the project, to accommodate the varied standard, but this is at the discretion of the Guarantor. 6) Variances are issued only for the project-specific issue identified in the written request, and do not constitute general permission to depart from the published requirements in this Standard, for any aspect of the same project or for future projects, designed or constructed by any other firm.

1.1.4. General Design Requirements

1.1.4.1. Waterproofing Roof Assemblies

1) Any membrane used in an assembly that will detain standing water to a depth greater than 12.7 mm (1/2”) shall be deemed suitable for use under hydrostatic pressure only if approved in writing by the roof system manufacturer (see Article 1.3.2.4., “Contractor Submittals”).

1.1.4.2. Rainwater Detention and Release

1) Every vegetated roof system shall conform to the minimum rainwater detention and discharge rates published by the municipal or regional Code, By-law, or regulation having jurisdiction.

1.1.4.3. Protection of Vegetated Assemblies

(See Note A-1.1.4.3.) 1) Every roof must be designed to promote the growth and vitality of the vegetation, including (without limitation) 1) proper slope for drainage, 2) protection from wind, 3) protection from emissions, 4) protection from displacement and erosion, and 5) protection from concentrated reflected light. 2) Designated walkways for service access to rooftop mechanical equipment must be incorporated in the vegetated roof assembly design.

Section 1.2. Reserved

Section 1.3. Application

1.3.1. Reserved

1.3.2. All Systems

1.3.2.1. Responsibility for Construction

(See Article 10.1.3.2.) 1) The Contractor is responsible to deliver the project RoofStar Guarantee certificate and therefore the Contractor shall be responsible to ensure the vegetated roof assembly is complete and ready for review by the assigned Observer. 1.3.2.2. Workmanship 1) The installer of a vegetated roof system must take reasonable measures to protect the project from damage by other trades, during and at the completion of the project. 1.3.2.3. Trade Qualifications 1) Each installation of a vegetated roof system must be coordinated and supervised by a trained, qualified green roofing project manager who is an established employee of the Contractor. 2) Every qualified green roof project manager 1) Shall be journeyperson-certified as a professional roofer or possess comparable education and experience, 2) Shall have completed the project manager course offered by the RGC, and 3) Must hold a valid Green Roof Installation and Maintenance Professional (GRIMP) certificate issued by Green Roofs for Healthy Cities, or other training deemed equivalent by the Guarantor. 3) A Green Roof Professional (GRP) designation is recommended for project managers. 4) Installation of a RoofStar-guarantee vegetated roof assembly shall be conducted only by a qualified green roof installer. 5) Every qualified green roof installer shall employ 1) at least one person in a senior supervisory role who holds a Green Roof Professional (GRP) designation (documented equivalent training and experience will be considered acceptable by the Guarantor, provided it is also acceptable to the vegetated roof system manufacturer), and 2) at least one person in a field supervisory role who holds a valid Green Roof Installation and Maintenance Professional (GRIMP) certificate issued by Green Roofs for Healthy Cities, or who can demonstrate equivalency to the satisfaction of the Guarantor. 6) Maintenance of a vegetated roof system shall be undertaken only by a trained, established employees of a qualified green roof installer, and shall be supervised by a person who meets the qualifications a qualified green roof installer.

1.3.2.4. Contractor Submittals

1) The Contractor shall provide to the Guarantor, with the application for a RoofStar Guarantee, 1) design specifications and drawings issued for construction, for the vegetated roof system, 2) a copy of the maintenance contract between the Contractor and the qualified green roof installer, for maintenance of the vegetated roof system, and 3) a copy of the single source warranty agreement between the vegetated roof system manufacturer and the roof system manufacturer, when applicable. 2) The Contractor shall provide to the Guarantor, prior to issuance of a RoofStar Guarantee, 1) the designed securement of the vegetated roof system (including shop drawings), and when the design is custom-engineered (See Article 3.1.3.3.) the design package shall bear the original stamp of the registered professional who designed the system securement or validated the design (Ref. Part 3), 2) design drawings bearing the signed stamp of a registered professional, showing the securement of anti-shear retention measures on vegetated roof system designed for slopes greater than 22° (See Article 2.1.3.2.), 3) the design and monitoring arrangements (if any) for electronic leak detection (ELD), 4) the certificate from the growing media supplier, certifying the soil’s origins and specifications (See Article 7.2.1.1.), 5) written approval from the roof system manufacturer stating that the application of the waterproofing membrane is suitable for use under hydrostatic pressure (applicable only when the design requires the detention of standing water to a depth greater than 12.7 mm (1/2”) in so-called “blue-green” roof systems; see Article 1.1.4.1.), 6) maintenance logs from the qualified green roof installer, and 7) a copy of the vegetated roof system manufacturer warranty for the vegetated roof system. 3) The Contractor shall, as part of its obligations under policy, ensure that the qualified green roof installer submits maintenance logs to the Guarantor demonstrating that the vegetated roof system is maintained according to the requirements of this Standard (Ref. Article 11.3.2.2.).

1.3.3. Reserved

1.3.4. Reserved

Part 2 – Structural Support and Safety

Section 2.1. Design

2.1.1. General

2.1.1.1. Scope

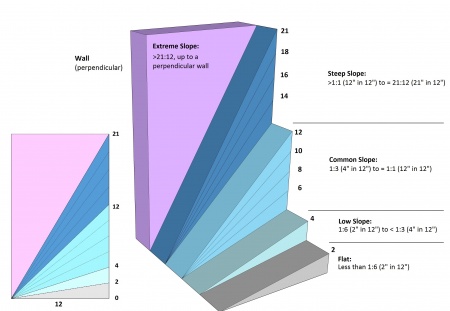

1) The scope of this Part and the Standard shall be as described in Division A, Part 1. 2.1.1.2. Defined Terms 1) Words that appear in italics are defined in the Glossary. Additionally, the following terms are used in this Part: 1) Angle of repose means the steepest angle at which particular loose material is stable. 2) Common Slope means a roof with a slope 1:3 (4” in 12”, or 18°), up to and including 1:1 (12” in 12”, or 45°). 3) Extreme Slope means a roof with a slope greater than 21:12 (21” in 12”, or 84°). 4) Flat (roof) means a roof with a slope less than 1:6 (2” in 12”, or 9°). 5) Low Slope means a roof with a slope 1:6 (2" in 12", or 9°, up to but less than 1:3 (4” in 12”, or 18°). 6) Steep Slope means a roof with a slope greater than 1:1 (12” in 12”, or 45°) up to and including 21:12 (21” in 12”, or 84°). 7) Supporting deck ("deck") means the "structural surface to which a roof system is applied" (adapted from ASTM D1079-18 Standard Terminology Relating to Roofing and Waterproofing).

2.1.2. Guarantee Term Requirements

2.1.2.1. RoofStar 2-year Guarantee for Vegetated Roof Assemblies

1) To qualify for a RoofStar 2-year Guarantee for Vegetated Roof Assemblies, all projects shall comply with the requirements in Article 1.1.2.1., the requirements in this Part, and the requirements of the Standard governing the supporting roof assembly.

2.1.2.2. Reserved

2.1.3. Roof Slope

2.1.3.1. General Requirements for Roof Slope

1) All roof assemblies that support a vegetated roof system shall be constructed with a minimum slope of 1:50 (1/4” in 12”; 1 degree or 2%), measured on the primary sloped planes of the roof assembly (See Note A-2.1.3.1.(1); also see Article 1.1.1.9., “Suitability of Design”). 2) Roofs with slopes greater than 1:1 (12” in 12”; 45° or 100%) do not qualify for a RoofStar Guarantee.

2.1.3.2. Vegetated Roof Systems on Slopes Greater Than 1:6

1) All vegetated roof assemblies with a designed slope greater than 1:6 (2” in 12”) shall be reviewed by the Design Authority to ensure that any and all materials in the green roof system resist slippage (shear loads) (See Article 1.1.1.9.; also see Article 3.3.4.1. and 7.1.4.1.). 2) When the design slope of a vegetated roof system exceeds the greater of the angle of repose for loose materials, or 1:1.25 (4.75” in 12”, or 22°), the design must be reviewed and accepted by the Authority Having Jurisdiction (AHJ), and its acceptance by the AHJ, along with the engineering of anti-shear measures (stamped by a Registered Professional) shall be submitted by the Contractor as information to be kept on file by the Guarantor, in the application for a Guarantee (Ref. Article 1.3.2.4.).

2.1.3.3. Reserved

2.1.4. Structural and Life Safety

2.1.4.1. Structural Loads

(See Note A-2.1.4.1.) 1) All load calculations shall be performed by a registered professional skilled in the work concerned. 2) The structural design for the roof should allow for loads during construction of the vegetated system, and for loads arising during potential repairs. 3) The Design Authority is responsible to determine all loads arising from the construction of the specified vegetated roof system, and must consider (without limitation) 1) seismic shear loads, 2) the dead load of the vegetated roof systems when fully mature and saturated with water, and 3) live loads during construction and after commissioning, including environmental loads such as rain and snow, expected for the building’s size and location, 4) shear ("drag") loads (See Article 3.3.4.1.), 5) loads from other overburden (Ref. Part 14 in the related waterproofing roof Standard), and 6) thermal expansion and contraction of the roof system components. 4) The determination of structural loads should incorporate the practices and test methods published in the following documents: 1) ASTM E2397/E2397M – 15, “Standard Practice for Determination of Dead Loads and Live Loads Associated with Vegetative (Green) Roof Systems”. 2) ASTM E2399/E2399M – 15, “Standard Test Method for Maximum Media Density for Dead Load Analysis of Vegetative (Green) Roof Systems”.

2.1.4.2. Specified Wind Loads

1) The Design Authority shall design the vegetated roof system to resist displacement by expected wind conditions (See Part 3 in this Standard for wind resistance requirements).

2.1.4.3. Fire Safety

1) The Design Authority is responsible to determine the level of fire safety for the VRS, based on the design standards published in ANSI/SPRI VF-1, “External Fire Design Standard for Vegetative Roofs”. 2) When the organic content of the growing media exceeds 20% by volume, the supporting roof assembly should have a ULC Class A rating, but this is subject to requirements of the Code having jurisdiction (See Article 1.1.1.9. and Article 7.1.3.1.).

2.1.4.4. Occupant and Maintenance Worker Safety

1) When a VRS is intended for human access, the Design Authority is responsible to incorporate into the roof design fall protection measures (including protection around skylights and clerestory windows) that conform to the requirements of the By-law or Building Code having jurisdiction, and to WorkSafeBC regulations. 2) A roof supporting a vegetated roof system shall be designed to protect maintenance workers from fall hazards (See Article 1.1.3.3.).

2.1.5. Roof Decks

2.1.5.1. Suitability of Roof Deck

1) A roof deck must conform to the requirements in Sub-section 2.1.5. of the applicable Standard for the supporting roof assembly. 2) When a wood structure supports a vegetated roof system, the deck and any vertical planes that contact the vegetated roof system should be pressure-treated tongue-and-groove plywood at least 19.05 mm (3/4”) thick, but when the existing deck and adjoining wall surfaces are untreated wood, they should be overlaid with no less than one layer of pressure-treated tongue-and-groove plywood at least 12.7 mm (1/2”) thick, secured with material-compatible screw fasteners (See Note A-2.1.5.1.).

2.1.6. Expansion and Control Joints

2.1.6.1. General Requirements

1) Expansion and control joint (roof divider) design shall conform to the requirements of the specified membrane roof system Standard and shall be isolated from the vegetated roof system with a separation zone (Ref. Article 5.1.3.2.) 2) Expansion joints must be elevated at least 203.2 mm (8”) above the finished roof system surface, a requirement which may not be reduced through a written Variance.