Working Page 2

Working Page 2

Division B - Standards

Waterproofing Roof Systems: Flexible Membranes (Polymer-modified Bituminous)

RGC Standard for SBS-modified Bitumen Membrane Roofs

This Standard is a consolidation of requirements previously published in the Roofing Practices Manual for Flexible Membrane Roofing Systems. It is comprised of fourteen (14) Parts that contain the requirements, guiding principles, recommendations and informative materials necessary for a roof to qualify for a RoofStar 5-Year Guarantee, RoofStar 10-Year Guarantee or RoofStar 15-year Guarantee. Requirements to qualify for a RoofStar 15-Year Guarantee are listed in each relevant Part under Section 1. All RoofStar 15-Year Guarantee requirements must be read together with the General Requirements for each Part in this Standard.

Notes to the Standard are hyperlinked from each Part and can be read by using the link in the Table of Contents for the Standard. Highlighted text within the body of the Standard indicates revisions made within the last twelve (12) months.

This Standard follows a specific structure, incorporates defined terms, and utilizes coloured text to denote specific meaning; this is explained in Division A, Part 2, "Structure and Organization of RPM and Standards". When the requirements in this Standard conflict with other resources found either in this Manual or in manufacturer's published instructions, the rules for Authority and Conflict in Division A, Article 2.3.1.2. shall be applied.

Readers are advised to review relevant materials that can be accessed through the hyperlinks embedded in the body of text.

First Edition: June 14, 2018

Previous Edition: October 20, 2023

Current Edition: Adopted October 25, 2024

All changes to this Standard are effective

November 1, 2024

© RCABC 2025

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.

Part 1 - General

This Part addresses the general and administrative requirements for the design and construction of a roof assembly, including full or partial roof replacement.

Section 1.1. Design

1.1.1. General

1.1.1.1. Scope

- The scope of this Part and the Standard shall be as described in Division A, Part 1.

- In addition to the Scope described in Division A, this Standard applies to the design and construction of roof systems that are site-built, or which may be factory fabricated, in part or in their entirety.

1.1.1.2. Coverage and Limitations

- Coverage under the RoofStar™ Guarantee shall be as described in Division A, Article 3.2.1.2.

1.1.1.3. References

- In this Standard, all references to

- the "British Columbia Building Code" (the "Building Code", or the "Code"), to municipal or regional building codes or regulations, or to other standards, presume the current edition that is in force,

- materials mean those materials expressly accepted by the Guarantor, unless stated otherwise, and

- measurements are shown in metric units first, followed by Imperial values (typically in parentheses; see Division A, Article 2.1.3.2., "Measurements").

1.1.1.4. Defined Terms

- Words that appear in italics are defined in the Glossary. Additionally, the following terms are used in this Part and the Standard:

- Design Authority means the individual or firm responsible for the issuance of project specifications and details to which the project will be bid and constructed. When a Contractor designs a project, the Contractor is deemed to be the Design Authority.

- Finished roof system surface means the top surface of any roof system, inclusive of ballast or overburden.

- Grade-level waterproofing system means an insulated or uninsulated system, designed and constructed at grade with a sheet or liquid-applied membrane, to exclude water.

- Linear metal flashing means flashings cut and shaped from flat metal stock, to redirect water at roof perimeters and edges, or to control the flow of water in valleys and drainage spillways. Linear metal flashings also protect roof membranes from weathering and damage and provide an aesthetic finish to the roof system.

- Guarantor (used interchangeably with RGC) means the RCABC Guarantee Corporation, which offers the RoofStar Guarantee.

- Membrane system means the combination of field and flashing membranes which function together to waterproof underlying materials and systems.

- Observer means a firm or person paid by the building Owner (directly, or through the RGC), who is independent (not a member) of the RCABC, and who is accepted by the RGC to provide Quality Assurance reviews during construction and after completion of the project, according to the terms and conditions set out in RCABC policy .

- Vegetated Roof Assembly (VRA), used interchangeably in the "RGC Standard for Vegetated Roofs" with green roof or green roofing, means a functional arrangement of interacting components, inclusive of vegetation, that is designed in conjunction with a supporting roof assembly, is intended to both grow and flourish, and is often installed on a roof to control the rate of rainwater discharged through a storm drainage system .

- Waterproofing roof system means an insulated or uninsulated roof system, designed and constructed on roofs using a sheet or liquid-applied membrane, to exclude water. This type of system typically is installed on roof slopes less than 1:4 (3” in 12”).

- Water-shedding roof system means an insulated or uninsulated roof system, designed and constructed to shed water away from a structure, not to waterproof it. This type of system typically is installed on roof slopes greater than 1:4 (3” in 12”) but may be installed on slopes as low as 1:6 (2" in 12").

1.1.1.5. Reserved

1.1.1.6. Objectives

- Every roof system shall conform to the more stringent of this Standard or the Building Code or By-law having jurisdiction.

1.1.1.7. Responsibility for Design

- Each design of a roof system shall be undertaken by a person or persons qualified in the work concerned (See Article 3.1.3.1. with respect to the securement of the roof assembly).

- The Coordinating Registered Professional is responsible for ensuring the design of the vegetated roof assembly complies with all applicable building, energy, and fire codes having jurisdiction.

1.1.1.8. Pre-Design Requirements

- The Coordinating Registered Professional is responsible to ensure that the roof assembly design is a multi-disciplinary enterprise that aligns with the designs for structural, plumbing, mechanical, electrical, architectural, and building envelope, together with all trades whose work intersects with the Contractor’s scope of work, to minimize out-of-sequence operations that could compromise the integrity of the completed roof assembly.

1.1.1.9. Suitability of Design

- The Design Authority is responsible for determining the appropriate roof assembly design and must consider (without limitation)

- the requirements of the building code having jurisdiction,

- the structural capabilities or limitations of the building,

- fire resistance and the roof class requirements for the building,

- wind loads (See Part 3 of this Standard),

- the effects of nearby structures on the roof assembly,

- the potential effects of reflected heat on the roof assembly,

- roof system aesthetics, and

- maintenance requirements, including the safety of maintenance workers.

- When the roof is intended as a platform to support a vegetated roof system, the supporting roof assembly must be suitable for that purpose (See Sentence 1.1.3.1.(2)).

1.1.2. Guarantee Requirements

1.1.2.1. RoofStar 5-Year Guarantee and RoofStar 10-year Guarantee

- To qualify for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, all projects shall comply with the requirements in this Part.

- In addition to Sentence (1), all projects shall comply with

- the project specifications and drawings, and

- the manufacturer's published installation requirements.

1.1.2.2. RoofStar 15-Year Guarantee

- To qualify for a RoofStar 15-year Guarantee, all projects shall comply with the requirements in this Standard for a RoofStar 5-year Guarantee or RoofStar 10-year Guarantee, together with the following:

- Each project must be designed and constructed in compliance with both the RoofStar Guarantee Standards, together with the membrane manufacturer’s available 20-year System Warranty standards.

- Where enhanced roof system securement is required by the manufacturer, which may exceed the securement required in a Tested Assembly, an Assembly with Proven Past Performance or a custom-engineered securement, the project must comply with the higher securement requirements.

- On all "new construction" projects, where external access is not provided, all roofs with a field elevation greater than 7620 mm (25’) above grade must incorporate safe, appropriate access to the roof, for example by incorporating stairs and a doorway or a properly located roof hatch (Safe, appropriate access to the roof is recommended for existing buildings, to facilitate maintenance and ongoing performance reviews).

- Moisture surveys for Membrane Replacement projects must be documented and submitted in report form to the Guarantor for review and consideration prior to tender; documented testing means a moisture survey scan performed by a qualified person, and

- at least three (3) cut tests for roof areas up to 20,000 sf (200 squares), or one (1) cut test for every 2000 sf (20 squares), whichever is more,

- one (1) cut test for every 3000 sf (30 squares) of roof area that exceeds the first 20,000 sf (200 squares), or

- one (1) cut test for each small roof area measuring no more than 200 sf (2 squares).

- Membrane Replacement projects must incorporate new insulation overlays in keeping with the requirements published in Part 8, Insulation Overlays.

- Materials left in place for partial roof system replacement must be scanned for moisture (Article 1.1.4.3.).

- All roofs (new construction and replacement roofing) must be built with a minimum slope of 2% (1:50) (Article 2.1.2.2.).

- All replacement roofing must utilize crickets to enhance drainage around curbs and sleepers (Article 2.1.2.2.).

- On new construction roofs, curbs and sleepers wider/longer than 1219.2 mm (48") must incorporate crickets to improve drainage (Article 7.1.2.2.).

- An insulation overlay is required on all conventionally insulated roof systems (Article 8.1.2.2.).

- Only certain membranes will qualify for a RoofStar 15-year Guarantee (Article 9.1.2.2.).

- All drains and overflows require clamping rings, and overflows are required for each roof area (Article 11.1.2.2.).

- Enhanced penetration flashing requirements (Article 12.1.2.2.).

- Linear metal flashings must be fabricated from 24-gauge material (Article 13.1.2.2.).

1.1.2.3. Quality Control

- Notwithstanding any other requirements in this Standard, the Contractor shall

- bid the project to meet the more stringent of this Standard or the project specifications,

- bid the project to include only RGC-accepted systems and materials,

- ensure that the supporting roof assembly conforms to the requirements and limitations of Article 1.1.3.1.,

- notify the Observer at least 24 hours before construction is scheduled to start or resume (72 hours notice is required for projects further away than 100 km),

- ensure that construction conforms to this Standard and exhibits good workmanship,

- ensure that samples, reports, shop drawings, ELD arrangements, certificates, manufacturer approvals, warranty documentation, and all other submittals are collected and provided to the Guarantor as required in Article 1.3.2.4., and

- abide by all pertinent RCABC policies.

1.1.2.4. Quality Assurance

(See Note A-1.1.2.4. )

- Notwithstanding any other requirements in this Standard, the Observer shall

- verify that the materials used in construction are accepted by the Guarantor and listed in Division C of this Manual,

- review the construction of the roof system (according to the prescribed number of observations, with consideration for the expected duration of construction) for conformance with the more stringent of

- this Standard,

- conditions and limitations in Division A of the RPM, as they apply,

- the manufacturer’s published requirements,

- the project drawings and specifications, or

- the Building Code having jurisdiction.

- review and report whether the Contractor has met the RCABC policy requirements noted in this Standard, and

- perform cut tests or other acceptable methods, whenever required, to verify that the materials and methods of construction conform to this Standard (for example, this may be required when the Contractor has completed more than 30 squares of roofing without an observation).

1.1.3. All Systems

1.1.3.1. Permitted Roof Systems

(See Note A-1.1.3.1.)

- This Standard applies to new construction, and to the partial or complete replacement of existing roofs, constructed as

- Uninsulated systems in which the membrane is bonded directly to the roof deck or an overlay, and is exposed to the weather and to sunlight,

- Conventionally insulated systems, sometimes referred to as Compact Roofs, in which the membrane is installed above insulation and other roof system materials, and is exposed to the weather and to sunlight,

- Protected roof systems, also referred to as “inverted”, in which the membrane is installed beneath other roof system or protection materials (usually insulation), and is protected from exposure to the weather and from sunlight, and

- Modified protected roof systems, which combine the functions and benefits of both a conventionally insulated system and a protected roof system, and where the membrane is protected from exposure to the weather and to sunlight.

- Where the roof is intended to support a vegetated roof system and qualify for a RoofStar Vegetated Roof Guarantee, only a new roof or a roof that is specified for a complete roof system replacement will qualify for the Guarantee (See Article 1.1.4.2. and Article 1.3.3.2. ).

1.1.3.2. Accessibility for Maintenance

- All roofs with a field elevation greater than 7620 mm (25’) above grade should incorporate access to the roof by stairs and a doorway or with a properly located roof hatch.

- Any hatch, ladder or mechanical unit should be located a sufficient distance away from the roof edge (setback zone) so that other fall protection measures are not required by those using or accessing this equipment.

- When it is not possible to situate a hatch, ladder, or mechanical unit outside the setback zone, guard rails should be designed for the roof edge to provide additional fall protection for those using or accessing such equipment.

- Each roof should be designed to provide safe access for maintenance of roof drains, corners, or mechanical equipment, where the roof is at least 3 m (10’) above the surface of the ground, or where a hazard to a person exists, should a fall be possible (this principle also applies to roof areas intended for regular occupancy); design elements to mitigate fall hazards should align with the Code having jurisdiction, and with the Workers Compensation Act Regulations, and should include

- tall parapets,

- guardrails, or

- tie-off anchors.

- Where a roof is intended to support a vegetated roof system, the roof must satisfy the design and pre-construction requirements published in the “RGC Standard for Vegetated Roofs”.

1.1.3.3. Membrane Integrity Testing

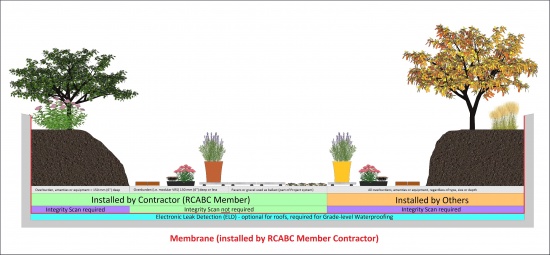

(See Note A-1.1.3.3. and Figure 1.1.3.3.-A )

- Electrical current membrane integrity testing shall conform to

- ASTM D7877, "Standard Guide for Electronic Methods for Detecting and Locating Leaks in Waterproof Membranes", or

- ASTM D8231, "Standard Practice for the Use of Low Voltage Electronic Scanning System for Detecting and Locating Breaches in Roofing and Waterproofing Membranes."

- An electrical current membrane integrity test is required when anyone other than the Contractor installs overburden, amenities, or equipment, (In this Standard, the term "electrical current membrane integrity test" means a test method that uses electrical current and electronic sensing technology to detect breaches in the membrane system).

- An electrical current membrane integrity test is required when the Contractor installs overburden, amenities, or equipment, but only when

- the total project area (footprint), inclusive of planters or other waterproofed features, exceeds 18.58 m2 (200 sf), and

- overburden, amenities, or equipment exceed 152.4 mm (6”) in depth .

- When the roof assembly supports a vegetated roof system covered by a RoofStar Guarantee an electrical current membrane integrity test is optional (not required) but recommended . An electrical current membrane integrity test is required immediately prior to the installation of a vegetated roof system .

- An electrical current membrane integrity test must be performed by an RGC-recognized service provider listed in Division C.

- Flood testing employed as a secondary or alternative membrane integrity test is strongly discouraged for conventionally insulated roof systems because of the risk of extensive damage to system components or the building interior, and is best suited for protected roof systems (See Note A-1.1.3.3.(5)).

- If flood testing is specified, it shall be conducted prior to the installation of insulation and roof coverings, and must be executed in keeping with ASTM D5957, "Standard Guide for Flood Testing Horizontal Waterproofing Installations".

1.1.3.4. Electronic Leak Detection

(See Note A-1.1.3.4.)

- Electronic Leak Detection (ELD), when specified by the Design Authority, shall conform to

- ASTM D7877, "Standard Guide for Electronic Methods for Detecting and Locating Leaks in Waterproof Membranes", or

- ASTM D8231, "Standard Practice for the Use of Low Voltage Electronic Scanning System for Detecting and Locating Breaches in Roofing and Waterproofing Membranes."

- Electronic Leak Detection (ELD) is optional for waterproofing roof systems, but strongly recommended

- for projects where multiple trades will have access to a roof that is under construction and completed, to identify breaches in the waterproofing membrane in a timely way and avoid future costly delays,

- when the roof assembly protects a sensitive occupied space (i.e., data centres, hospitals, critical infrastructure), or

- when the roof supports any type of overburden, amenities, or equipment, including a vegetated roof system .

- When Electronic Leak Detection is specified, it shall provide detection capabilities for all waterproofed surfaces, and should extend at least 50.8 mm (2") vertically from the drainage plane at

- all transitions,

- any point along the entire deck perimeter, and

- protrusions.

1.1.3.5. Hot Works

(See Note A-1.1.3.5.)

- The Design Authority may specify that the Contractor must maintain compliance with the RCABC Hot Works Program and consequently manage the Hot Works conducted on site (See Article 1.3.2.1.).

- When the project involves Hot Work, the Design Authority must either

- pre-approve alternate applications already written in this Standard or another applicable Standard published in this Manual, when the specified application is deemed to be fire-sensitive by the Contractor as part of the risk assessment process, or

- provide alternate material and application requirements in the Specification for fire sensitive locations on the project.

1.1.3.6. Variances

- When a design is unable to conform to the Standard, the Design Authority may apply to the RGC for a written Variance.

- Application for a written Variance must be made in writing (email correspondence is common), and must

- identify the project name and its civic address,

- identify the RoofStar Guarantee number (if assigned),

- identify the Contractor (if awarded),

- articulate the nature of the design problem,

- identify the RoofStar Guarantee requirement to be varied, and state the desired modification (i.e., reduce the requirement for 203.2 mm (8") to 152.4 mm (6")),

- cite the reference to which the Variance will apply (i.e., Standard name, article number, sentence number, etc.), and

- provide design drawings, photographs, and roof plans, referencing grid lines that identify or articulate the boundaries to which the Variance will be applied.

- Variances are issued by the RGC only to the Design Authority and will be distributed to the Contractor.

- A Variance may be unrestricted in its scope, or it may include one or more conditions, or a restriction in coverage, that will affect the design and construction of the project, to accommodate the varied standard, but this is at the discretion of the Guarantor.

- Variances are issued only for the project-specific issue identified in the written request, and do not constitute general permission to depart from the published requirements in this Standard, for any aspect of the same project or for future projects, designed or constructed by any other firm.

- A Variance for a vegetated roof assembly shall conform to the requirements in Article 1.1.3.6. of the “RGC Standard for Vegetated Roofs”.

1.1.4. Replacement and Alterations

(The requirements in Subsection 1.1.3., "All Systems", shall be read together with the following Articles) (See Note A-1.1.4.)

1.1.4.1. General Requirements

- Unless expressly permitted otherwise in this Standard, the design for replacement roofing shall conform to the requirements for new roofing in this Standard.

1.1.4.2. Complete Roof System Replacement

- Complete roof system replacement shall conform to the general requirements in Article 1.1.4.1., unless expressly varied elsewhere in this Standard.

- Roof system replacement means the complete removal and replacement of all roof system and metal flashing materials, exclusive of the air or vapour control layers, and only new replacement materials shall be installed.

- Subject to the requirements in Part 6, "Air and Vapour Controls", the decision to reuse and repair an existing air or vapour control layer remains the responsibility of the Design Authority.

- Roof system replacement projects are eligible to qualify for a RoofStar 5-year Guarantee, RoofStar 10-year Guarantee, or a RoofStar 15-year Guarantee, subject to their respective requirements.

1.1.4.3. Partial Roof Replacement

- Partial replacement of roof systems is permitted by the Guarantor, but coverage under the Guarantee is limited to new materials supplied and installed by the Contractor.

- Retention of insulation materials in a roof system is subject to the requirements for insulation in Part 7.

- Membrane replacement, which is limited to the removal and replacement of the roof membrane and materials adhered to the membrane,

- may be specified without a written Variance from the Guarantor, and

- may qualify for a RoofStar 5-year Guarantee and RoofStar 10-year Guarantee, provided

- the Design Authority is certain the existing roof system is properly secured to the existing deck structure (See Part 3, "Securing the Roof Assembly"),

- the existing roof system is demonstrably dry and free of any wet materials (wet materials must be replaced, in order to qualify for a RoofStar Guarantee),

- the existing field membrane will be removed,

- a new insulation overlay will be supplied and installed, together with a new roof membrane,

- existing membrane flashing will be removed and replaced with new materials, and

- the design conforms to the requirements in this Standard for new roof construction.

- To qualify for a RoofStar 15-year Guarantee, membrane replacement projects must conform to the requirements of this Article and shall include the removal and replacement of the insulation overlay (Ref. Article 1.1.2.2.).

1.1.4.4. Membrane Recovering

(See Note A-1.1.4.4. )

- Recovering (installing a new membrane system over an existing membrane system)

- may qualify for both a RoofStar 5-year Guarantee and a RoofStar 10-year Guarantee, but only if it is permitted under a written Variance issued by the Guarantor prior to the tendering of documents (recovering is not a recommended practice and will limit the scope of coverage under the RoofStar Guarantee), and

- does not qualify for a RoofStar 15-year Guarantee.

- Membrane recovering, which is a type of roof system replacement, does not qualify for a RoofStar Vegetated Roof Guarantee .

- A RoofStar Guarantee issued for a recovered roof is limited strictly to the value of new roof system materials; existing materials that remain in place beneath new materials are not covered by the RoofStar Guarantee.

- All membrane recovering project specifications and drawings shall reflect and conform to the construction requirements in Article 1.3.3.4.

- Before proceeding with roof recovering, the Design Authority should consider

- the requirements for moisture testing (described below),

- testing securement of materials to be left in place, and

- the potential consequences of failure for the building and its use.

- To qualify for a written Variance from the Guarantor, the Variance request (See Article 1.1.3.6.)

- must identify the type of roof system to which the Variance pertains (i.e., uninsulated, conventionally insulated, protected, or modified protected roof system),

- must indicate how the new roof system will be secured (See Part 3, "Securing the Roof Assembly"),

- must specify how the existing roof system will be physically separated from other roof areas, and

- must include the formal independent report that describes the condition of the existing roof system, and which documents results from cut tests and moisture investigation that are prerequisites for a RoofStar Guarantee.

- Uninsulated and protected roof systems presented to the Guarantor in a written Variance application by the Design Authority must be

- free of blisters and breaches in the membrane,

- independently surveyed by qualified professionals, when they are constructed on a wood deck, using calibrated moisture detection equipment, and

- cut open and probed for moisture and deterioration when any moisture is detected in a wood deck (the results of such investigation must be formally documented for review by the Guarantor).

- Conventionally insulated and modified protected roof systems presented to the Guarantor in a written Variance application by the Design Authority must be independently surveyed by qualified professionals using calibrated moisture detection equipment and cut tests, and the resulting survey shall be formally documented for review by the Guarantor.

- All cut test surveys performed on conventionally insulated systems

- shall be independently documented for review by the Guarantor,

- must be performed using ASTM D7636/D7636M-11, "Standard Practice for Sampling and Analysis of Modified Bitumen Roof Systems", and

- shall be no fewer than

- three (3), for roof areas up to 20,000 sf (200 squares), or one (1) for every 2,000 sf (20 squares), whichever is more,

- one (1) for every 3000 sf (30 squares) of roof area that exceeds the first 20,000 sf (200 squares), and

- one (1) for each small roof area equal to or less than 200 sf (2 squares).

- When a conventionally insulated roof system

- is structurally sloped, at least half (50%) of the required cut tests shall sample the roof in or near valleys, and near roof drains.

- is structurally flat, samples shall be taken near roof drains and in a random pattern across the roof.

- All wet material identified by either the independent moisture detection survey or through cut tests shall be specified for removal.

1.1.4.5. Tie-ins, Additions, and Alterations to Existing Roofing

- Where a new roof adjoins and ties into an existing roof, the two areas must be isolated and separated by a control joint securely attached to the structure and waterproofed in keeping with the requirements in both Article 10.1.6.2., "Control Joints (Roof Dividers)", and Part 10, "Perimeters and Walls".

- If project conditions do not allow for a curb joint, the Design Authority must submit an alternative design and obtain a written Variance from the Guarantor that permits the elimination of curb joints (see Article 1.1.3.6., "Variances"); any alternative design

- must include design specifications and construction details showing a positive water cut-off that fully isolates the existing roof system from the new roof system, and

- shall show how the new roof system will be easily distinguishable from the existing roof system.

- Repairs or renovations to an existing roof system that is not covered by a RoofStar Guarantee do not qualify for a RoofStar Guarantee (the term "renovation" means the removal and replacement of, or the application of a cover to, a portion of the roof system).

- Modifications or additions to a guaranteed roof are permissible, subject to various conditions, but must be made by a Contractor qualified to perform work under the RoofStar Guarantee Program.

1.1.5. Reserved

Section 1.2. Reserved

Section 1.3. Application

1.3.1. Reserved

1.3.2. All Systems

1.3.2.1. Hot Works: Contractor Requirements

- The Contractor must maintain the requirements of the RCABC Hot Works Program, including (without limitation)

- Insurance Coverage, wherein the limits carried on the Contractor’s policy must equal or exceed the minimum requirements set by RCABC, and coverage must be unhindered by warranties that limit or exclude coverage when Hot Works is required,

- Education and training, since workers who perform Hot Works must be trained by the Contractor and kept current with acceptable methods,

- the "British Columbia Fire Code", wherein a Fire Safety Plan, preventative methods or alternative work procedures, fire watches, and the use and placement of equipment at the project site must comply with the BC Fire Code requirements for Hot Work,

- a Fire Safety Plan, whereby

- the Contractor must assess the hazards to property and persons and produce a written Fire Safety Plan prior to the start of work, and

- the Fire Safety Plan must be kept on the project site and must be kept current until the project is completed,

- RoofStar Guarantee Standards, to which the Contractor must conform, at each juncture where the interface of different membranes applications constitutes part of the Fire Safety Plan,

- a Fire Watch, in which the Contractor must, as part of the Fire Safety Plan, conduct a fire watch

- that complies with the "British Columbia Fire Code",

- is assigned to competent, trained personnel using suitable equipment, including the use of a hand-held infrared thermometer, and

- is documented in a written fire watch log, and

- Hot Works Notification, wherein the Contractor shall notify the project authority or the AHJ, as and when required, that Hot Works will be performed.

1.3.2.2. Workmanship

(See Note A-1.3.2.2.)

- The Contractor must take reasonable measures to protect the project from damage by the weather, during and at the completion of the project.

- Open penetrations and flashings must be temporarily sealed off from the weather, even when other trades are responsible to make a permanent seal or install overlapping materials (See Article 4.2.1.1.).

1.3.2.3. Contractor Qualifications

- Supervision and installation of a RoofStar-guaranteed waterproofing roof system may be conducted only by established employees of the Contractor, and every project must be supervised by a Journeyperson employee who holds a valid ticket.

- A Journeyperson may supervise a maximum of three (3) apprentices and/or three (3) labourers (Ref. RCABC Policy A-248).

1.3.2.4. Contractor Submittals

- The Guarantor must receive from the Contractor, prior to construction of the project and to document the roof system record,

- a Tested Assembly report supplied or endorsed by a manufacturer, including documentation of the substitution of any materials identified in that test report,

- a letter in support of an Assembly with Proven Past Performance , as required in Article 3.1.4.3.(2), or

- a custom-engineered system for securing the roof assembly.

- The Contractor shall submit to the Guarantor, before a RoofStar Guarantee is issued, any and all required samples, reports, shop drawings, ELD arrangements, certificates, manufacturer approvals, or warranty documentation (required for a RoofStar 15-year Guarantee).

1.3.3. Replacement and Alterations

(The requirements in Subsection 1.3.2., "All Systems", shall be read together with the following Articles)

1.3.3.1. General Requirements

- Unless expressly permitted otherwise in this Standard, all replacement roofing shall conform to the requirements for new roofing in this Standard.

1.3.3.2. Complete Roof System Replacement

- See the requirements throughout this Standard, which apply to both new construction and replacement of a roof system.

1.3.3.3. Partial Roof Replacement

- See the requirements throughout this Standard, which apply to both new construction and replacement of a roof membrane.

1.3.3.4. Membrane Recovering

(See Article 1.1.4.4.)

- All wet material identified by either the independent moisture detection survey or through cut tests shall be removed in the course of construction.

- When recovering uninsulated systems,

- deteriorated wood decks must be repaired with new material of like kind and quality; a new roof system shall not be installed on a compromised deck,

- the existing membrane system must be

- clean and free of debris, gravel, or blisters, and

- cut at the perimeter change in plane to relieve any tension or distortions in the membrane, and

- the existing field and flashing membranes must be overlaid with a mechanically attached, inorganic moisture-resistant insulation overlay board acceptable to the Guarantor, secured to conform to the requirements in Part 3.

- When recovering conventionally insulated systems, the existing membrane must be cut through

- in a grid pattern measuring no larger than 6m x 6m (approximately 20' x 20'), and

- around the perimeter of the roof area, no more than 0.2 m (8") from the edge.

- A grid-cut field membrane must be overlaid with a mechanically attached, inorganic moisture-resistant insulation overlay board acceptable to the Guarantor.

- When expanded polystyrene insulation (EPS) is present in an existing roof system, the existing membrane must be overlaid with at least one layer of 50.8 mm (2”) mineral wool or polyisocyanurate insulation, in combination with a RoofStar-accepted insulation overlay board (as required).

- New membrane system materials must be properly secured to the underlying roof assembly.

- All membrane recovering projects must incorporate only new

- strip-in flashings for roof penetrations (Ref. Part 12),

- roof drains (cast-iron roof drains in usable condition are exempted from this requirement; see Article 11.3.3.2.), and

- linear metal flashings (Ref. Part 13).

1.3.3.5. Tie-ins, Additions, and Alterations to Existing Roofing

- Where a new roof adjoins and ties into an existing roof, the two areas must be isolated and separated by a curb joint securely attached to the structure and waterproofed in keeping with the requirements for control joints ( Article 10.1.6.2. and Article 10.3.6.2.).

- If the Design Authority has obtained from the Guarantor a written Variance that permits the elimination of curb joints, the new roof system must be fully isolated from the existing roof system with a positive water cut-off that renders the new roof system easily distinguishable from the existing roof system.

1.3.3.6. Repairs and Modifications

- When a roof system that is covered by an active (unexpired) RoofStar Guarantee has been damaged or otherwise requires repairs, work shall conform to the specifications of the material manufacturers, and to the requirements in this Standard, with respect to (without limitation)

- the securement of new materials ( Part 3),

- deck or wall overlays ( Part 5),

- continuity of air and vapour controls ( Part 6),

- thermal resistance and insulation overlays ( Part 7 and Part 8),

- membranes ( Part 9),

- membrane flashing ( Part 10),

- drains ( Part 11),

- penetrations and curbs ( Part 12), and

- linear metal flashings ( Part 13).

- Modifications to an existing roof system covered by an active (unexpired) RoofStar Guarantee, including (without limitation) the addition of new curbs, drains, or penetrations, shall conform to all the requirements in this Standard, or as otherwise stated.