CS Details:E3.7.3 (Hip & Ridge Caps)

CS Details:E3.7.3 (Hip & Ridge Caps)

| RoofStar Guarantee Standards are blue-linked |

1 WORK INCLUDED

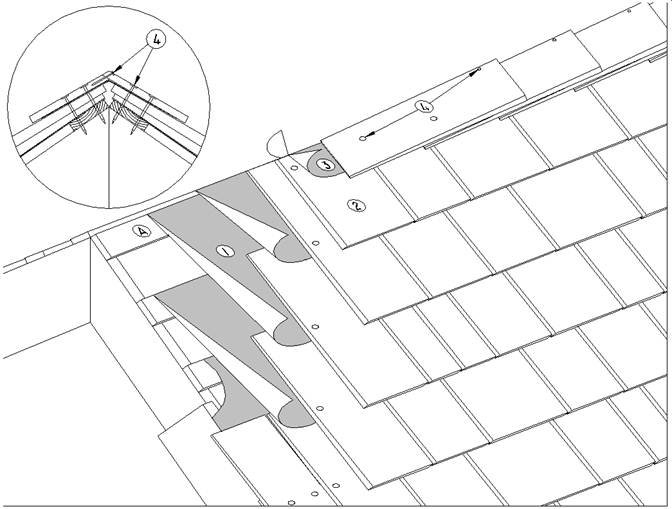

(1) Interrlay: Minimum No. 15 asphalt saturated felt not less than 450 mm (18") shall be laid between courses of cedar shakes starting from a distance equal to double the weather exposure from the butt. On open sheathing top edge of interlay must rest on and be secured to the strapping.

(2) Final Course: Trim final course to top point of ridge or hip.

(3) Ridge Underlay: A strip of minimum No. 15 asphalt saturated felt prior to capping.

(4) Ridge Caps: Optional locations for second nail. All ridges and hips shall be of the alternate overlap type and at the same exposure as the field of the roof. Each side shall be fastened with 2 nails not in the same line of grain (staggered). Nails should be longer than the field nails and long enough to penetrate the sheathing a minimum of 20 mm (3/4") or in the case of plywood, completely through the sheathing, OR 1 nail per side and an additional nail through the butt end edge at peak of ridge caps (staples alone are not sufficient).

2 RELATED WORK BY OTHERS

(A) Sheathing: Minimum 19 mm x 89 mm (1" x 4") boards spaced to match exposure of shakes or shingles, though minimum 19 mm x 140 mm (1" x 6") boards are mandatory for 24" shakes. Solid sheathing is also acceptable.

NOTE: • Refer to RGC Guarantee Standards for additional requirements.

Back to Cedar Shakes & Shingles Application