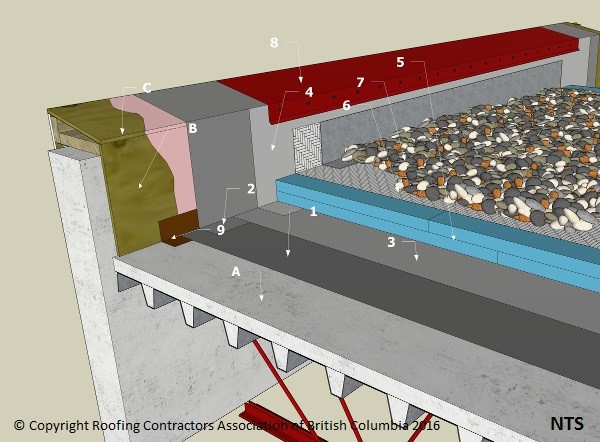

SBS Protected Roof Assembly (typical)

SBS Protected Roof Assembly (typical)

Revision as of 20:40, 25 August 2016 by James Klassen (talk | contribs)

| To read RoofStar Guarantee Standards for any element in this illustration, click on the blue-linked terms |

1 WORK INCLUDED

- (1) Base Sheet

- Adhered to deck using asphalt, cold adhesive, self-adhered, torch applied membrane or loose laid according to manufacturer's specification and to the RoofStar Guarantee Standards.

- (2) Base Sheet Flashing

- Adhered according to manufacturer's specifications using cold adhesive, self-adhered or torch applied to cover boards, or mechanically attached membrane. Torching directly to wood surfaces is not permitted. Must be carried over to outside of parapet or minimum 200 mm (8") above finished roof surface (see RoofStar Guarantee Standards for SBS Roofing Systems, 10.3).

- (3) Cap Sheet

- Applied according to manufacturer’s printed instructions and RoofStar Guarantee Standards.

- (4) Cap Sheet Flashing

- Applied according to manufacturer’s printed instructions and RoofStar Guarantee Standards to top of parapet or minimum 200 mm (8") above top of finished roof surface.

- (5) Insulation

- See available insulation products in the Accepted Materials section of this Manual.

- (6) Filter Fabric

- Metal base flashing required. See ;Section 12.

- (7) Ballast

- Gravel or concrete paving tiles.

- (8) Metal Flashing

- As required by RoofStar Guarantee Standards.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- Smooth, dry and clean concrete, coated with proprietary primer.

- (B) Plywood Backing

- Required on rough concrete or where stripping adhesion is asphalt. Must be primed.

- (C) Sloped Wood Blocking

- Sloped to roof where parapet is over 100 mm (4") in width.

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.