Difference between revisions of "SBS Sealant Pocket"

Difference between revisions of "SBS Sealant Pocket"

(→RELATED WORK BY OTHERS) |

|||

| Line 1: | Line 1: | ||

| − | [[File:10.3.5.4.jpg]] | + | <div class="panel panel-success"> |

| + | <div class="panel-heading"><big>'''SBS Details'''</big></div> | ||

| + | <div class="panel-body"> | ||

| + | <div class="col-md-6"> | ||

| + | <div style="text-align:center; vertical-align:center"> | ||

| + | [[File:10.3.5.4.jpg|class=img-responsive]] | ||

| + | </div> | ||

| + | </div><!-- COL-MD-6 --> | ||

| + | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

;(1) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSSUBSTRATES|'''Gypsum Deck Overlay''']]: If required by design authority. | ;(1) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSSUBSTRATES|'''Gypsum Deck Overlay''']]: If required by design authority. | ||

| Line 20: | Line 28: | ||

;(B) '''Protrusion''' | ;(B) '''Protrusion''' | ||

;(C) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSWOODBLOCKING|'''Wood Blocking''']] | ;(C) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSWOODBLOCKING|'''Wood Blocking''']] | ||

| − | + | </div><!-- COL-6-MD --> | |

| + | </div><!-- PANEL BODY --> | ||

| + | </div><!-- PANEL --> | ||

'''NOTE''': Refer to '''''RoofStar Guarantee Standards''''' for additional requirements. | '''NOTE''': Refer to '''''RoofStar Guarantee Standards''''' for additional requirements. | ||

Revision as of 18:08, 19 August 2016

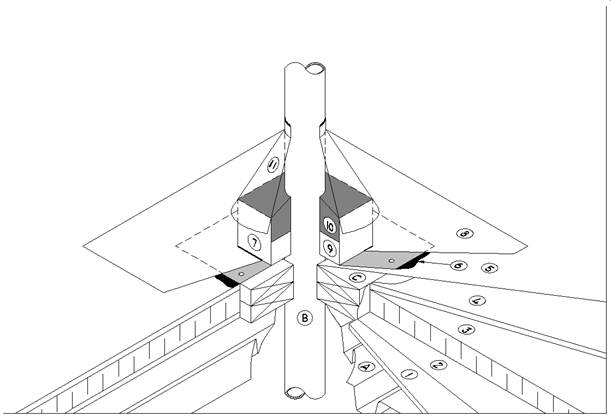

SBS Details

1 WORK INCLUDED

- (1) Gypsum Deck Overlay

- If required by design authority.

- (2) Vapour Retarder

- If required by design authority

- (3) Insulation

- Mechanically fastened. See available insulation products in the Accepted Materials section of this Manual.

- (4) Insulation Overlay Board

- As required.

- (5) Primary Membrane and Membrane Protection

- (6) Compatible Mastic

- Use only the membrane manufacturer's approved sealant.

- (7) Gum Pan or Pitch Pocket

- Minimum 100 mm (4") flange onto roof membrane. All corners, with the exception of one job-site formed double standing seam corner joint and adjoining lapped flange joining, shall be closed and soldered. Minimum height of gum pan to be 100 mm (4").

- (8) Membrane Flashing

- Onto primed metal flashing flange.

- (9) Packing

- To prevent displacement of compatible mastic.

- (10) Structural Sealant

- Use only the membrane manufacturers’ approved proprietary polyurethane based structural sealant.

- (11) Back-up Storm Collar

- To be installed whenever practical. Caulk at top of collar.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Protrusion

- (C) Wood Blocking

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

- WARNING: DO NOT USE THIS DETAIL WITH HOT PIPES.

- AVOID THIS DETAIL: Wherever possible use Flanged Metal Stack Flashing or Curbed Opening (See Section 10.3).