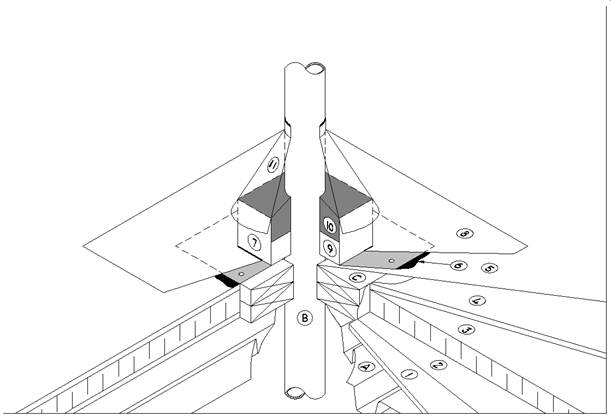

SBS Sealant Pocket

SBS Sealant Pocket

1 WORK INCLUDED

(1) Gypsum Overlay Board: If required by design authority.

(2) Vapour Retarder: If required by design authority.

(3) Insulation: See list of accepted materials in Section 2.2.

(4) Insulation Overlay: As required. See RGC Guarantee Standard B4.1, B4.2 and C4.1

(5) Primary Membrane and Membrane Protection

(6) Compatible Mastic: Use only the membrane manufacturers’ approved sealant.

(7) Metal Gum Pan or Pitch Pocket: Minimum 100 mm (4") flange onto roof membrane. All corners, with the exception of one job-site formed double standing seam corner joint and adjoining lapped flange joining, shall be closed and soldered. Minimum height of gum pan to be 100 mm (4"). See RGC Guarantee Standard A6.2

(8) Membrane Flashing: Onto primed metal flashing flange.

(9) Packing: To prevent displacement of compatible mastic.

(10) Structural Sealant: Use only the membrane manufacturers’ approved proprietary polyurethane based structural sealant.

(11) Back-up Storm Collar: To be installed whenever practical. Caulk at top of collar.

2 RELATED WORK BY OTHERS

(A) Acceptable Deck

(B) Protrusion

(C) Wood Blocking

- NOTE

- WARNING: DO NOT USE THIS DETAIL WITH HOT PIPES.

- AVOID THIS DETAIL: Wherever possible use Flanged Metal Stack Flashing or Curbed Opening (See Section 10.3).

- NOTE: Refer to RGC Guarantee Standards for additional requirements.