Difference between revisions of "SBS Window Opening"

Difference between revisions of "SBS Window Opening"

(→WORK BY OTHERS) |

|||

| Line 3: | Line 3: | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

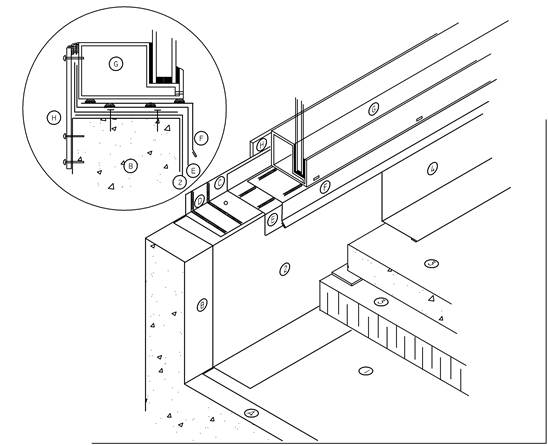

| − | (1) | + | ;(1) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSBASE|'''Primary Roof Membrane''']]: Installed per RoofStar Guarantee Standards |

| − | + | ;(2) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSSTRIPTERM|'''Membrane Flashing''']]: Carried up walls a minimum 200 mm (8") above roof surface. At window curbs membrane flashing must be 200mm (8") in height above the top of extruded polystyrene insulation or protection/drainage layer, extended under the window mullion (fenestration assembly) and carried to the inside edge of the curb. Membrane gussets must be installed at all corners and transitions. | |

| − | (2) | + | ;(3) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSDRAINAGE|'''Protection/Drainage Layer''']] '''- Insulation Surfacing''': Assemblies to be determined by Design Authority. Paver systems are required to have proprietary pedestals that incorporate a minimum 3mm (1/8") gap between adjacent units. See additional RoofStar Guarantee Standards under [[RoofStar Guarantee Standards for SBS Roof Systems#SBSBALLAST|'''8.4.3 Protected and Modified Protected Membranes - Ballast''']]. |

| − | + | ;(4) [[RoofStar Guarantee Standards for SBS Roof Systems#METALCAP-SBS|'''Metal Wall Flashing''']]: Required on roof assemblies using gravel ballast, filter mats and drainage mediums at insulation /curb interfaces. | |

| − | (3) | ||

| − | |||

| − | (4) | ||

=== WORK BY OTHERS === | === WORK BY OTHERS === | ||

| − | (A) | + | ;(A) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSDECKS|'''Acceptable Deck''']]: Concrete slab shown |

| − | + | ;(B) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSCURB|'''Supporting Curb''']]: Height varies depending on the insulation thickness and type of roof assembly. | |

| − | (B) | + | ;(C) <b>Metal Water Stop Flashing:</b> Mechanically attached to the top of the window curb. Cut flashing to fit the opening and pan fold, weld, or solder seams at all corners and mitres. |

| − | + | ;(D) <b>Metal Water Stop Flashing Seam: </b>Overlap metal water stop joints a minimum of 150mm (6") and seal joints with two rows of structural sealant. | |

| − | (C) <b>Metal Water Stop Flashing:</b> Mechanically attached to the top of the window curb. Cut flashing to fit the opening and pan fold, weld, or solder seams at all corners and mitres. | + | ;(E) <b>Building Envelope Membrane Flashing:</b> Must be compatible with and overlap the roof membrane flashing. Membrane gussets must be installed at all corners and transitions. |

| − | + | ;(F) [[RoofStar Guarantee Standards for SBS Roof Systems#METALCAP-SBS|'''Metal Cap Flashing''']]: Adhere metal cap flashing to membrane flashing with a membrane compatible structural sealant. Mechanical attachment of metal flashing through the membrane flashing is not acceptable. | |

| − | (D) <b>Metal Water Stop | + | ;(G) <b>Fenestration Assembly: CAUTION – </b>Securement fasteners <b>MUST NOT</b> penetrate the metal or membrane flashing. |

| − | + | ;(H) <b>Fenestration Assembly Securement Bar – ONLY </b>fasten securement bar through upper vertical leg of the window mullion (frame). | |

| − | (E) <b>Building Envelope Membrane Flashing:</b> Must be compatible with and overlap the roof membrane flashing. Membrane gussets must be installed at all corners and transitions. | ||

| − | |||

| − | (F) | ||

| − | |||

| − | (G) <b>Fenestration Assembly: CAUTION – </b>Securement fasteners <b>MUST NOT</b> penetrate the metal or membrane flashing. | ||

| − | |||

| − | (H) <b>Fenestration Assembly Securement Bar – ONLY </b>fasten securement bar through upper vertical leg of the window mullion (frame). | ||

Revision as of 17:44, 4 August 2016

1 WORK INCLUDED

- (1) Primary Roof Membrane

- Installed per RoofStar Guarantee Standards

- (2) Membrane Flashing

- Carried up walls a minimum 200 mm (8") above roof surface. At window curbs membrane flashing must be 200mm (8") in height above the top of extruded polystyrene insulation or protection/drainage layer, extended under the window mullion (fenestration assembly) and carried to the inside edge of the curb. Membrane gussets must be installed at all corners and transitions.

- (3) Protection/Drainage Layer - Insulation Surfacing

- Assemblies to be determined by Design Authority. Paver systems are required to have proprietary pedestals that incorporate a minimum 3mm (1/8") gap between adjacent units. See additional RoofStar Guarantee Standards under 8.4.3 Protected and Modified Protected Membranes - Ballast.

- (4) Metal Wall Flashing

- Required on roof assemblies using gravel ballast, filter mats and drainage mediums at insulation /curb interfaces.

2 WORK BY OTHERS

- (A) Acceptable Deck

- Concrete slab shown

- (B) Supporting Curb

- Height varies depending on the insulation thickness and type of roof assembly.

- (C) Metal Water Stop Flashing: Mechanically attached to the top of the window curb. Cut flashing to fit the opening and pan fold, weld, or solder seams at all corners and mitres.

- (D) Metal Water Stop Flashing Seam: Overlap metal water stop joints a minimum of 150mm (6") and seal joints with two rows of structural sealant.

- (E) Building Envelope Membrane Flashing: Must be compatible with and overlap the roof membrane flashing. Membrane gussets must be installed at all corners and transitions.

- (F) Metal Cap Flashing

- Adhere metal cap flashing to membrane flashing with a membrane compatible structural sealant. Mechanical attachment of metal flashing through the membrane flashing is not acceptable.

- (G) Fenestration Assembly: CAUTION – Securement fasteners MUST NOT penetrate the metal or membrane flashing.

- (H) Fenestration Assembly Securement Bar – ONLY fasten securement bar through upper vertical leg of the window mullion (frame).

NOTE: Refer to RGC Guarantee Standards for additional requirements.