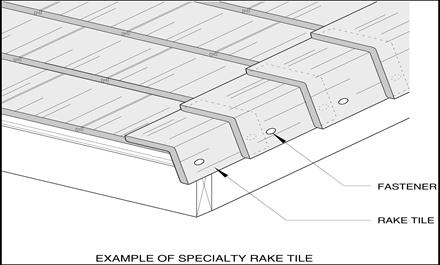

TS Details:E4.7.2 (Tile - Rake Edge)

TS Details:E4.7.2 (Tile - Rake Edge)

Rake tiles cover the exposed edge of field tiles at fascia boards. This helps prevent wind driven rain from entering the system and provides an attractive finish. Rake tiles “butt” against the lower edge of the field tile courses then are fastened with two nails into the fascia.

Flashings:

Flashings bridge the gap between field areas and any protrusions such as pipes, vents, and adjoining walls. Because these items impede the flow of water, small deficiencies can cause high amounts of water to enter the building. Proper detail work will make the difference between a successful or problematic roof.

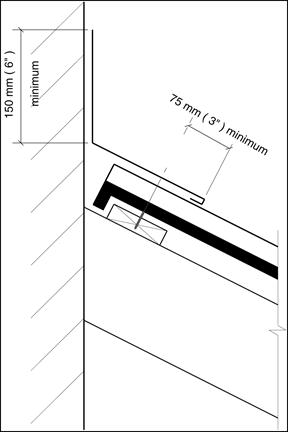

Pipe Flashings:

Pipe flashings are made of lead which conforms well to the tiles’ surface. They are applied over the course of tile penetrated by the pipe and under the next course with a 75 mm (3") min. lap.

Flashing for a wall termination should lap the tile by a minimum of 100 mm (4"). Material should be the 26 ga. prepainted galvanized with S locks or standing seams to join lengths.

A mortar or mastic bedding should be applied to the tops of the concrete tile before flashing to prevent wind blown rain or vermin from entering.

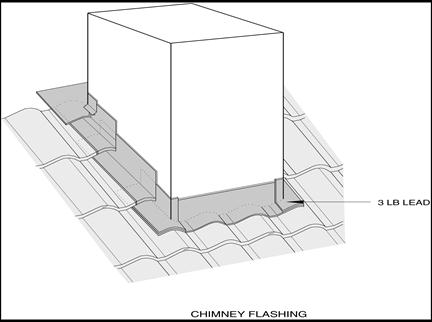

Curb Flashings:

Curb flashings are applied around skylights, chimneys or other larger penetrations. The basic principle is to deflect the water rushing against the uproof side, safely around then on top of the tiles on the down roof side.

The recommended method is to use 3 lb. lead sheeting due to its malleability and, therefore, easy conformance to the tile’s contour.

Upper and lower flashings should be conformed with tile’s surface.Upper flashings should extend 150 mm (6") past corners on each side, then formed around soakers.

Lower flashing should extend 100 mm (4") past corners and lapped under the soakers.