Difference between revisions of "TS Details:E4.7.8 (Slate - Valleys)"

Difference between revisions of "TS Details:E4.7.8 (Slate - Valleys)"

(Created page with "<hr> Valleys on a slate roof can be done in several ways including swept, laced, mitred and open. The recommended style for B.C. is open valleys, due to ease of installation a...") |

|||

| Line 1: | Line 1: | ||

| − | < | + | <div class="panel panel-success"> |

| + | <div class="panel-heading"><big>'''Slate Roofing Details'''</big></div> | ||

| + | <div class="panel-body"> | ||

| + | <div class="col-md-6"> | ||

| + | <div style="text-align:center; vertical-align:center"> | ||

| + | |||

| + | [[File:7.4.1.2.4.jpg|class=img-responsive]] | ||

| + | |||

| + | [[File:7.4.1.2.5.jpg|class=img-responsive]] | ||

| + | </div> | ||

| + | </div><!-- COL-MD-6 --> | ||

| + | |||

| + | <div class="col-md-6"> | ||

| + | |||

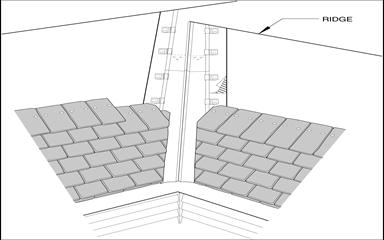

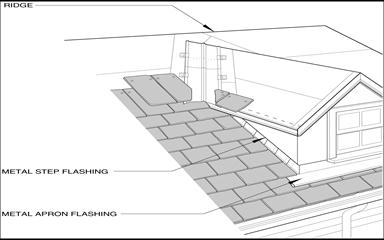

Valleys on a slate roof can be done in several ways including swept, laced, mitred and open. The recommended style for B.C. is open valleys, due to ease of installation and better drainage of debris. It is recommended that copper, lead or stainless steel be used to match the longevity of slate. | Valleys on a slate roof can be done in several ways including swept, laced, mitred and open. The recommended style for B.C. is open valleys, due to ease of installation and better drainage of debris. It is recommended that copper, lead or stainless steel be used to match the longevity of slate. | ||

Valley metal should be a minimum of 600 mm (24") wide and be centre crimped. Successive pieces should lap a minimum 150 mm (6"). Valley metal sections should be drag load fastened and sealed between laps with a compatible caulking. Slates should extend a minimum of 150 mm (6") into the valley with the cut line being tapered 1% from bottom to top. | Valley metal should be a minimum of 600 mm (24") wide and be centre crimped. Successive pieces should lap a minimum 150 mm (6"). Valley metal sections should be drag load fastened and sealed between laps with a compatible caulking. Slates should extend a minimum of 150 mm (6") into the valley with the cut line being tapered 1% from bottom to top. | ||

| − | + | </div><!-- COL-6-MD --> | |

| − | + | </div><!-- PANEL BODY --> | |

| − | + | </div><!-- PANEL --> | |

| − | |||

<hr> | <hr> | ||

| Line 12: | Line 24: | ||

| − | [[Section:E. Application: Steep Slope Roofs|<i class="fa fa-chevron-circle-left fa | + | [[Section:E. Application: Steep Slope Roofs|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Slate Application'']] |

| − | [[Tile and Slate Construction Details|<i class="fa fa-chevron-circle-left fa | + | [[Tile and Slate Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Tile and Slate Construction Details'']] |

| − | [[Section:G. Construction Details|<i class="fa fa-chevron-circle-left fa | + | [[Section:G. Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] |

Revision as of 21:19, 19 August 2016

Slate Roofing Details

Valleys on a slate roof can be done in several ways including swept, laced, mitred and open. The recommended style for B.C. is open valleys, due to ease of installation and better drainage of debris. It is recommended that copper, lead or stainless steel be used to match the longevity of slate.

Valley metal should be a minimum of 600 mm (24") wide and be centre crimped. Successive pieces should lap a minimum 150 mm (6"). Valley metal sections should be drag load fastened and sealed between laps with a compatible caulking. Slates should extend a minimum of 150 mm (6") into the valley with the cut line being tapered 1% from bottom to top.