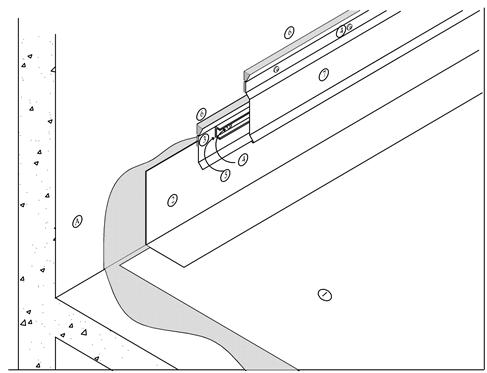

WP Details:F1.7.10 (Walls - Double Surface Reglet Flashing)

WP Details:F1.7.10 (Walls - Double Surface Reglet Flashing)

1 WORK INCLUDED

(1)Primary Waterproofing Membrane: Fully adhered to acceptable substrates (concrete slab depicted), installed as per RGC Guarantee Standards E and Membrane Manufacturer's installation specifications.

(2) Membrane Flashing: Carried up wall minimum 200 mm (8") above deck surface and minimum 100 mm (4") above top of finished permeable wearing course or overburden.

(3) Primary Surface Reglet: Install as detailed with steel channel and concrete pins. Adhered membrane termination held in place by clamping pressure and pins.

(4) Fasteners: Suitable expanding type concrete pins.

(5) Clamping Bar: Steel channel with elongated holes to permit expansion/contraction, pinned into concrete at maximum 400 mm (16") o/c. Bar dimensions to be a minimum 38 mm (1 ½") wide x 12 mm (1/2") thick C-channel, formed from a minimum 22 gauge galvanized or pre-finished steel.

(6) Caulking: Polyurethane sealant, fill to top of the flashing and crown to promote drainage.(7) Surface Reglet Counter Flashing: To cover lower reglet assembly, pinned directly without a clamping bar at maximum 300 mm (12") o/c. (Interlocking hooked type assembly optional)

2 RELATED WORK BY OTHERS

(A)Concrete, Stone or Steel Wall Finish: Must be dry, smooth and primed for membrane flashing to be adhered directly. (Plywood or fibre-mat reinforced cement board may be required).

NOTE: * AVOID SURFACE REGLET: (wherever possible) Use preformed or saw cut REGLETS:

- Refer to RGC Guarantee Standards E for additional requirements

Back to Waterproofing Application