Difference between revisions of "TS Details:E4.7.10 (Slate - Ridges)"

Difference between revisions of "TS Details:E4.7.10 (Slate - Ridges)"

| Line 32: | Line 32: | ||

| − | [[ | + | [[RoofStar Guarantee Standards for Tile & Slate Roof Systems|<i class="fa fa-chevron-circle-left fa" ></i> RoofStar Guarantee Standards for Tile & Slate Roof Systems]] |

[[Tile and Slate Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Tile and Slate Construction Details'']] | [[Tile and Slate Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Tile and Slate Construction Details'']] | ||

[[Section:G. Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] | [[Section:G. Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] | ||

Revision as of 18:58, 25 October 2016

| RoofStar Guarantee Standards are blue-linked |

Slate Roofing Details

Ridges have several traditional styles including saddled or a metal flashing. Ridges are installed after the field slates are installed flush with each other on opposite sides of the ridge.

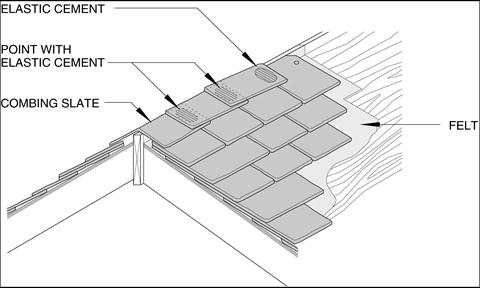

- Saddle Ridges

- The slates are run horizontally and overlapping with the nails being driven between slates of the last course. Elastic cement should be applied in overlaps and joints on top of the ridge.

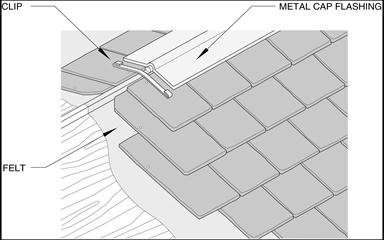

- Metal Ridge Cap

- Metal used for a ridge cap should be non-corrosive to last the life of a slate roof. It is installed on a ridge board and must cover the last course of slate down to its normal exposure. Attachment is provided by hidden clips.

RoofStar Guarantee Standards for Tile & Slate Roof Systems