Difference between revisions of "Template:Part 8 (Waterproofing Roofs - SBS)"

Difference between revisions of "Template:Part 8 (Waterproofing Roofs - SBS)"

(→All Projects) |

(→General) |

||

| (18 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

==General== | ==General== | ||

<ol> | <ol> | ||

| − | <li><span class="reference">Insulation overlay boards are installed in most | + | <li><span class="reference">Insulation overlay boards are installed in most ''Conventionally Insulated Systems'' to</span> |

<ol> | <ol> | ||

| − | <li><span class="reference">protect heat-sensitive insulation materials from damage by heat and flame</span>. | + | <li><span class="reference">protect ''heat-sensitive insulation'' materials from damage by heat and flame</span>. |

<li><span class="reference">protect insulation materials from accidental impact</span>. | <li><span class="reference">protect insulation materials from accidental impact</span>. | ||

| − | <li><span class="reference">provide dimensional stability to the roof system</span>. | + | <li><span class="reference">provide dimensional stability to the ''roof system''</span>. |

| − | <li><span class="reference">distribute dead loads from heavy overburdens or equipment installed on top of the finished | + | <li><span class="reference">distribute dead loads from heavy overburdens or equipment installed on top of the ''finished waterproofing system''</span>. |

<li><span class="reference">ensure the membrane performs as it should</span>. | <li><span class="reference">ensure the membrane performs as it should</span>. | ||

<li><span class="reference">provide a suitable substrate for membrane application</span>. | <li><span class="reference">provide a suitable substrate for membrane application</span>. | ||

</li></ol> | </li></ol> | ||

| − | <li><span class="reference">Insulation overlay boards may be mechanically attached or adhered, depending upon the insulation type and the design requirements of the roof assembly | + | <li><span class="reference">Insulation overlay boards may be mechanically attached or adhered, depending upon the insulation type and the design requirements of the entire ''roof assembly''. See more information on</span> [http://rpm.rcabc.org/index.php?title=Insulation_Joints_and_Overlays '''Insulation Joints and Overlays'''] <span class="reference">in ''Essential Elements''</span>. |

</li></ol> | </li></ol> | ||

| − | + | <div id="INSUL_OVERLAY_DESIGN"></div> | |

===Design=== | ===Design=== | ||

====RoofStar 15-Year Guarantee==== | ====RoofStar 15-Year Guarantee==== | ||

<ol> | <ol> | ||

| − | <li>An insulation overlay is required for all insulated systems, regardless of the insulation type, and overlays must | + | <li>An insulation overlay is required for all insulated ''systems'', regardless of the insulation type, and overlays must |

<ol> | <ol> | ||

<li>be at least 6.4 mm (1/4”) thick. | <li>be at least 6.4 mm (1/4”) thick. | ||

| Line 26: | Line 26: | ||

====All Projects==== | ====All Projects==== | ||

<ol> | <ol> | ||

| − | <li> | + | <li>{{hilite |{{hilite | Notwithstanding the requirements in '''Part 7''' concerning ''heat-sensitive insulation''|| 2021-June-30 }}, an insulation overlay of one or more layers is required over {{hilite | all flat and sloped ||2021-June-30 }} board-type insulation, {{hilite | and on insulation installed on vertical surfaces|| 2021-June-30 }}, when || 2021-February-7 }} |

| − | <li> | + | <ol> |

| − | <li>< | + | <li>{{hilite | the compressive strength of the insulation is less than 110 KPa (20 psi)|| 2021-February-7 }}. |

| − | <li> | + | <li>{{hilite | the membrane {{hilite | is self-adhered or|| 2021-June-30 }} will be applied with a torch flame, adhesives or hot bitumen|| 2021-February-7 }}. |

| + | <li>{{hilite | a ''Conventionally Insulated System'' supports an overburden; these ''roof systems'' must be designed with at least one layer of adhered composite insulation overlay|| 2021-June-30 }} | ||

| + | <ol> | ||

| + | <li>{{hilite | no less than 12.7 mm (½") thick|| 2021-June-30 }}. | ||

| + | <li>{{hilite | with a minimum compressive strength of 620 kPa (90 psi)|| 2021-June-30 }}. | ||

| + | </li></ol> | ||

| + | </li></ol> | ||

| + | <li>{{hilite | The requirement to use an insulation overlay does not apply to the field application of|| 2021-June-18 }} | ||

<ol> | <ol> | ||

| − | <li> | + | <li>{{hilite | self-adhered membranes|| 2021-June-30 }} |

| − | <li>with a | + | <ol> |

| + | <li>{{hilite | expressly accepted by the '''''Guarantor''''' for application directly on specific insulation types without the use of an overlay|| 2021-June-30 }}. | ||

| + | <li>{{hilite | expressly approved (in published literature) by the manufacturer for application directly on an insulation panel|| 2021-June-30 }}. | ||

| + | </li></ol> | ||

| + | <li>torch-applied membranes installed directly on mineral wool insulation treated with a thermofusible bitumen top surface. This exception is subject to the standards for mineral wool insulation published in '''Part 7 INSULATION'''. | ||

| + | </li></ol> | ||

| + | <li>When an overlay board is required over mineral wool insulation, the overlay board must be a moisture resistant fibreglass-faced silicon treated gypsum core board measuring at least 12.7 mm (1/2") thick. See also '''7.2 Materials''' concerning mineral wool insulation. | ||

| + | <li>{{hilite | ''Heat-sensitive'' crickets used in membrane systems applied with a torch flame or hot bitumen must be overlaid using either of the following approaches || 2021-June-18 }}: | ||

| + | <ol> | ||

| + | <li>one layer of panels, | ||

| + | <ol> | ||

| + | <li>at least 12.5 mm (1/2”) thick. | ||

| + | <li>offset from insulation joints by at least 300 mm (12”). | ||

| + | <li>continuously sealed with a flame-impervious tape along all joints with adjacent panels. | ||

| + | </li></ol> | ||

| + | <li>two layers of panels, | ||

| + | <ol> | ||

| + | <li>each at least 4.8 mm (3/16”) thick. | ||

| + | <li>offset from each other, from the adjacent layer, and from insulation joints by at least 300 mm (12”). | ||

| + | </li></ol> | ||

</li></ol> | </li></ol> | ||

<br> | <br> | ||

| − | See also '''14.1.2.1 General''' | + | See also '''14.1.2.1 General'''. |

</li></ol> | </li></ol> | ||

| + | <div id="INSUL_OVERLAY_MATERIALS"></div> | ||

==Materials== | ==Materials== | ||

| − | See [http://rpm.rcabc.org/index.php/Insulation_Overlays '''Insulation Overlays'''] accepted for use in '''''RoofStar Guaranteed''''' roof systems. | + | See [http://rpm.rcabc.org/index.php/Insulation_Overlays '''Insulation Overlays'''] accepted for use in '''''RoofStar Guaranteed''''' ''roof systems''. |

:{| class="wikitable" | :{| class="wikitable" | ||

|+ Table 8.1 Insulation Overlay Minimum Thicknesses | |+ Table 8.1 Insulation Overlay Minimum Thicknesses | ||

|- | |- | ||

| − | ! style="width: | + | ! style="width: 450px;vertical-align:centre;text-align:center;" | Overlay Type |

! style="width: 220px;vertical-align:centre;text-align:center;" | Minimum Thickness - mm (in.) | ! style="width: 220px;vertical-align:centre;text-align:center;" | Minimum Thickness - mm (in.) | ||

|- | |- | ||

| − | | Asphaltic core | + | | Asphaltic core || style="width: 100px;vertical-align:top;text-align:center;" | 4.8 (3/16") |

|- | |- | ||

| − | | Moisture- | + | | Moisture resistant fibreglass-faced silicon treated gypsum core || style="width: 100px;vertical-align:top;text-align:center;" | 6.4 (1/4") |

|- | |- | ||

| − | | High-density | + | | High-density insulation || style="width: 100px;vertical-align:top;text-align:center;" | 12.7 (1/2") |

|- | |- | ||

| − | | | + | | Membrane-laminated overlays and Composites || style="width: 100px;vertical-align:top;text-align:center;" | As listed in this ''Manual'' |

|- | |- | ||

| − | | Fibreboard || style="width: 100px;vertical-align:top;text-align:center;" | As listed in this | + | | Fibreboard || style="width: 100px;vertical-align:top;text-align:center;" | As listed in this ''Manual'' |

|- | |- | ||

| − | + | | Mineral wool || style="width: 100px;vertical-align:top;text-align:center;" | As listed in this ''Manual'' | |

| − | |||

| − | | Mineral wool || style="width: 100px;vertical-align:top;text-align:center;" | As listed in this | ||

|} | |} | ||

<ol> | <ol> | ||

<li>Regardless of the type of insulation overlay, the overall thickness of insulation overlay boards shall not exceed 50 mm (2”). Minimum allowable thicknesses are shown in '''Table 8.1''' above. | <li>Regardless of the type of insulation overlay, the overall thickness of insulation overlay boards shall not exceed 50 mm (2”). Minimum allowable thicknesses are shown in '''Table 8.1''' above. | ||

| − | <li>Asphalt | + | <li>{{hilite | Asphalt-coated|| 2021-June-30 }} fibreboard roof insulation adhered with hot asphalt or an asphalt-based adhesive must be asphalt-coated on the top and bottom surface (minimum coated two-sides). |

<li>Fire guard tape must be 150 mm (6”) wide | <li>Fire guard tape must be 150 mm (6”) wide | ||

<ol> | <ol> | ||

| Line 69: | Line 94: | ||

</li></ol> | </li></ol> | ||

</li></ol> | </li></ol> | ||

| − | + | <div id="INSUL_OVERLAY_APPLICATION"></div> | |

==Application== | ==Application== | ||

===General=== | ===General=== | ||

| Line 79: | Line 104: | ||

====All Projects==== | ====All Projects==== | ||

<ol> | <ol> | ||

| − | <li> | + | <li>See the Design requirements in '''8.1.1 Design'''. |

| + | <li>{{hilite | Fibreboard shall not be used as an insulation overlay beneath torch-applied membranes|| 2021-June-30 }}. | ||

| + | <li>{{hilite | Insulation overlays || 2021-June-30 }} | ||

<ol> | <ol> | ||

| − | <li>the | + | <li>{{hilite | should be square and should make firm, full contact with adjacent panels unless specified otherwise by the manufacturer|| 2021-June-30 }}. |

| − | <li>the insulation is | + | <li>{{hilite | must be offset at least 300 mm (12") from the joints of the insulation layer; a minus offset tolerance of 50 mm (2") maximum is permissible|| 2021-June-30 }}. |

</ol></li> | </ol></li> | ||

| − | <li> | + | <li>When multiple layers of an {{hilite | insulation|| 2021-June-30 }} overlay are specified, the joints between boards must be offset/staggered at least 300 mm (12") from adjacent layers and rows. See '''Figure 8.1'''. See also '''Part 7 INSULATION'''. |

| + | <br> | ||

| + | {| class="wikitable"; table style="background-color:white"; border="#A9A9A9;" | ||

| + | |+ '''Figure 8.1''' (Click to expand) | ||

| + | |- | ||

| + | | [[File:8.1 Insulation and Overlays.jpg| link=http://rpm.rcabc.org/images/9/9e/8.1_Insulation_and_Overlays.jpg |400 px]] | ||

| + | |} | ||

| + | <br> | ||

| + | <li>'''Mechanical securement''': | ||

<ol> | <ol> | ||

| − | <li>one | + | <li>When mechanically attaching insulation overlay boards, the insulation and overlay boards may be fastened together as one ''assembly''. Unless otherwise indicated by the system requirements in a ''Tested Assembly'', follow the fastener patterns set out in '''Part 3 SECURING the ROOF ASSEMBLY'''. |

| − | + | <li>When a membrane-laminated overlay is mechanically fastened over insulation, fasteners and plates used in the field of each panel must be covered with torch-applied polyester or composite-reinforced membrane patches that extend past the edge of each plate at least 50 mm (2”). | |

| − | |||

| − | <li> | ||

| − | |||

</ol></li> | </ol></li> | ||

| − | <li> | + | <li>'''Adhered securement''': |

<ol> | <ol> | ||

| − | <li> | + | <li>{{hilite | Adhered laminated membrane, composite or moisture resistant fibreglass-faced silicon treated gypsum core board overlays measuring at least 12.7 mm (1/2") thick must be used when|| 2021-June-30 }} |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |- | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<ol> | <ol> | ||

| − | <li> | + | <li>{{hilite | ''Conventionally Insulated Systems'' support ''overburden'' (overlays must provide compressive strength of at least 620 kPa (90 psi)|| 2021-June-30 }}. |

| − | + | <li>{{hilite | mandated by the standards for mineral wool insulation (see '''7.1.1.2'''('''11'''))|| 2021-June-30 }}. See also '''Part 14 The ROOF as a PLATFORM''' for design and construction standards. | |

| − | < | ||

| − | |||

| − | See '''14 The ROOF as a PLATFORM''' for design and construction standards | ||

| − | |||

| − | |||

</ol></li> | </ol></li> | ||

| − | + | <li>{{hilite | ''Roof system'' components adhered with two-component low-rise polyurethane foam must be|| 2021-June-30 }} | |

| − | |||

<ol> | <ol> | ||

| − | <li> | + | <li>{{hilite | installed immediately in wet adhesive (before a surface skin develops), applied|| 2021-June-30 }} |

<ol> | <ol> | ||

| − | <li> | + | <li>{{hilite | in parallel runs or in a Z-pattern, no more than 150 mm (6”) from any edge of the board and spaced no more than 300 mm (12”) apart|| 2021-June-30 }}. |

| + | <li>{{hilite | to a clean, dry and contaminant-free surface|| 2021-June-30 }}. | ||

| + | <li>{{hilite | in ribbon widths specified by the adhesive manufacturer or, in the absence of manufacturer requirements, 19 mm (3/4”) wide|| 2021-June-30 }}. | ||

| + | </ol></li> | ||

| + | <li>{{hilite | properly placed and weighted in wet adhesive until cured|| 2021-June-30 }}. | ||

| + | </ol></li> | ||

| + | <li>{{hilite | Hot bitumen used to adhere a ''roof assembly''|| 2021-June-30 }} | ||

<ol> | <ol> | ||

| − | <li> | + | <li>{{hilite | must be applied at minimum rates and temperatures based on the type of product, as published by the material manufacturer and in the '''RoofStar Guarantee Standards for Built-up Roof (BUR) Systems'''|| 2021-June-30 }}. |

| − | <li> | + | <li>{{hilite | may be applied on slopes up to 1/2:12 (for steeper slopes, select a different method of securement)|| 2021-June-30 }}. |

</ol></li> | </ol></li> | ||

| − | |||

</ol></li> | </ol></li> | ||

| − | |||

| − | |||

</ol></li> | </ol></li> | ||

| − | === | + | ===[NOT USED]=== |

| − | + | ||

| − | + | ===[NOT USED]=== | |

| − | |||

| − | |||

Latest revision as of 13:49, 14 April 2021

1 General

- Insulation overlay boards are installed in most Conventionally Insulated Systems to

- protect heat-sensitive insulation materials from damage by heat and flame.

- protect insulation materials from accidental impact.

- provide dimensional stability to the roof system.

- distribute dead loads from heavy overburdens or equipment installed on top of the finished waterproofing system.

- ensure the membrane performs as it should.

- provide a suitable substrate for membrane application.

- Insulation overlay boards may be mechanically attached or adhered, depending upon the insulation type and the design requirements of the entire roof assembly. See more information on Insulation Joints and Overlays in Essential Elements.

1.1 Design

1.1.1 RoofStar 15-Year Guarantee

- An insulation overlay is required for all insulated systems, regardless of the insulation type, and overlays must

- be at least 6.4 mm (1/4”) thick.

- possess a compressive strength of at least 690 kPa (100 psi).

1.1.2 All Projects

- Notwithstanding the requirements in Part 7 concerning heat-sensitive insulation, an insulation overlay of one or more layers is required over all flat and sloped board-type insulation, and on insulation installed on vertical surfaces, when

- the compressive strength of the insulation is less than 110 KPa (20 psi).

- the membrane is self-adhered or will be applied with a torch flame, adhesives or hot bitumen.

- a Conventionally Insulated System supports an overburden; these roof systems must be designed with at least one layer of adhered composite insulation overlay

- no less than 12.7 mm (½") thick.

- with a minimum compressive strength of 620 kPa (90 psi).

- The requirement to use an insulation overlay does not apply to the field application of

- self-adhered membranes

- expressly accepted by the Guarantor for application directly on specific insulation types without the use of an overlay.

- expressly approved (in published literature) by the manufacturer for application directly on an insulation panel.

- torch-applied membranes installed directly on mineral wool insulation treated with a thermofusible bitumen top surface. This exception is subject to the standards for mineral wool insulation published in Part 7 INSULATION.

- self-adhered membranes

- When an overlay board is required over mineral wool insulation, the overlay board must be a moisture resistant fibreglass-faced silicon treated gypsum core board measuring at least 12.7 mm (1/2") thick. See also 7.2 Materials concerning mineral wool insulation.

- Heat-sensitive crickets used in membrane systems applied with a torch flame or hot bitumen must be overlaid using either of the following approaches:

- one layer of panels,

- at least 12.5 mm (1/2”) thick.

- offset from insulation joints by at least 300 mm (12”).

- continuously sealed with a flame-impervious tape along all joints with adjacent panels.

- two layers of panels,

- each at least 4.8 mm (3/16”) thick.

- offset from each other, from the adjacent layer, and from insulation joints by at least 300 mm (12”).

See also 14.1.2.1 General. - one layer of panels,

2 Materials

See Insulation Overlays accepted for use in RoofStar Guaranteed roof systems.

Table 8.1 Insulation Overlay Minimum Thicknesses Overlay Type Minimum Thickness - mm (in.) Asphaltic core 4.8 (3/16") Moisture resistant fibreglass-faced silicon treated gypsum core 6.4 (1/4") High-density insulation 12.7 (1/2") Membrane-laminated overlays and Composites As listed in this Manual Fibreboard As listed in this Manual Mineral wool As listed in this Manual

- Regardless of the type of insulation overlay, the overall thickness of insulation overlay boards shall not exceed 50 mm (2”). Minimum allowable thicknesses are shown in Table 8.1 above.

- Asphalt-coated fibreboard roof insulation adhered with hot asphalt or an asphalt-based adhesive must be asphalt-coated on the top and bottom surface (minimum coated two-sides).

- Fire guard tape must be 150 mm (6”) wide

- self-adhering modified bituminous tape acceptable to the membrane manufacturer.

- Type IV fibreglass felt or No. 15 organic felt, applied with hot bitumen or cold adhesive.

3 Application

3.1 General

3.1.1 RoofStar 15-Year Guarantee

- See the requirements for a RoofStar 15-Year Guarantee in 8.1.1.1.

3.1.2 All Projects

- See the Design requirements in 8.1.1 Design.

- Fibreboard shall not be used as an insulation overlay beneath torch-applied membranes.

- Insulation overlays

- should be square and should make firm, full contact with adjacent panels unless specified otherwise by the manufacturer.

- must be offset at least 300 mm (12") from the joints of the insulation layer; a minus offset tolerance of 50 mm (2") maximum is permissible.

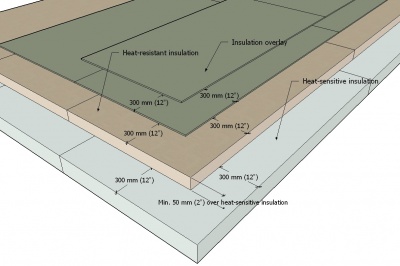

- When multiple layers of an insulation overlay are specified, the joints between boards must be offset/staggered at least 300 mm (12") from adjacent layers and rows. See Figure 8.1. See also Part 7 INSULATION.

Figure 8.1 (Click to expand)

- Mechanical securement:

- When mechanically attaching insulation overlay boards, the insulation and overlay boards may be fastened together as one assembly. Unless otherwise indicated by the system requirements in a Tested Assembly, follow the fastener patterns set out in Part 3 SECURING the ROOF ASSEMBLY.

- When a membrane-laminated overlay is mechanically fastened over insulation, fasteners and plates used in the field of each panel must be covered with torch-applied polyester or composite-reinforced membrane patches that extend past the edge of each plate at least 50 mm (2”).

- Adhered securement:

- Adhered laminated membrane, composite or moisture resistant fibreglass-faced silicon treated gypsum core board overlays measuring at least 12.7 mm (1/2") thick must be used when

- Conventionally Insulated Systems support overburden (overlays must provide compressive strength of at least 620 kPa (90 psi).

- mandated by the standards for mineral wool insulation (see 7.1.1.2(11)). See also Part 14 The ROOF as a PLATFORM for design and construction standards.

- Roof system components adhered with two-component low-rise polyurethane foam must be

- installed immediately in wet adhesive (before a surface skin develops), applied

- in parallel runs or in a Z-pattern, no more than 150 mm (6”) from any edge of the board and spaced no more than 300 mm (12”) apart.

- to a clean, dry and contaminant-free surface.

- in ribbon widths specified by the adhesive manufacturer or, in the absence of manufacturer requirements, 19 mm (3/4”) wide.

- properly placed and weighted in wet adhesive until cured.

- installed immediately in wet adhesive (before a surface skin develops), applied

- Hot bitumen used to adhere a roof assembly

- must be applied at minimum rates and temperatures based on the type of product, as published by the material manufacturer and in the RoofStar Guarantee Standards for Built-up Roof (BUR) Systems.

- may be applied on slopes up to 1/2:12 (for steeper slopes, select a different method of securement).

- Adhered laminated membrane, composite or moisture resistant fibreglass-faced silicon treated gypsum core board overlays measuring at least 12.7 mm (1/2") thick must be used when