Difference between revisions of "Asphalt Shingles - Diverter Flashing"

Difference between revisions of "Asphalt Shingles - Diverter Flashing"

(→RELATED WORK BY OTHERS) |

|||

| Line 1: | Line 1: | ||

| + | {{Template:RPM Info}} | ||

| + | |||

{| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | {| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | ||

| colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span style="color:#6495ed">'''blue-linked'''</span></big> | | colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span style="color:#6495ed">'''blue-linked'''</span></big> | ||

Revision as of 22:05, 26 July 2021

| RoofStar Guarantee Standards are blue-linked |

Asphalt Shingle Details

1 WORK INCLUDED

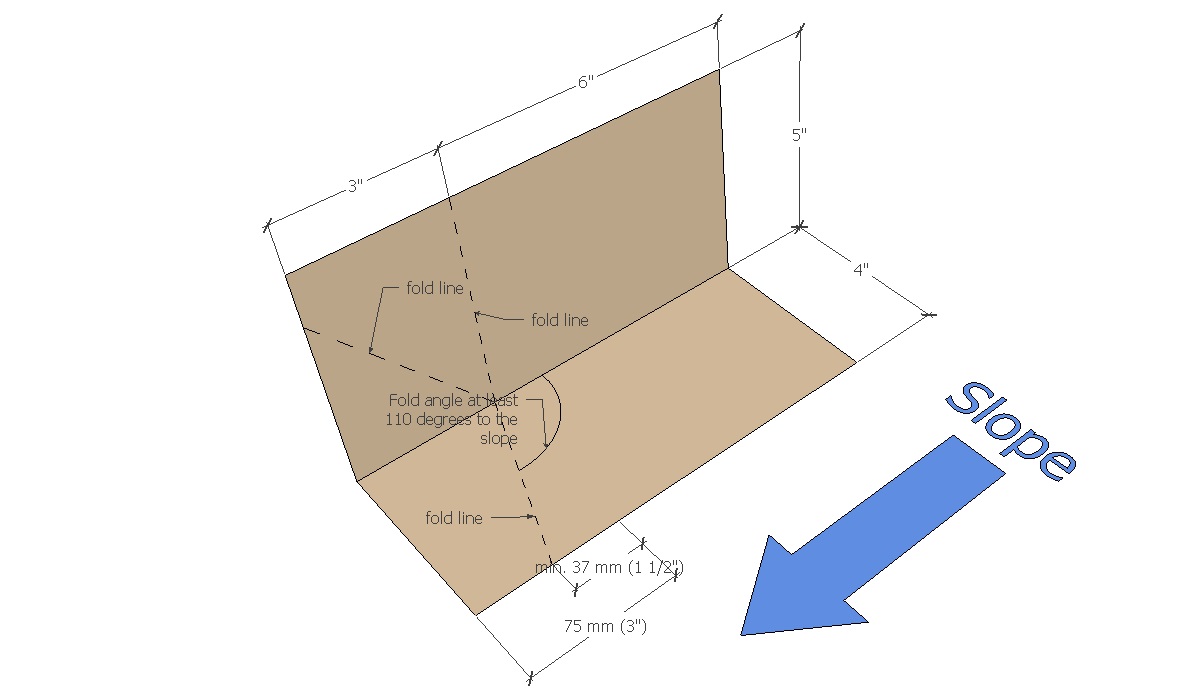

- (1) Step 1

- Use a standard 225 mm (9”) long step flashing and scribe the fold lines as shown on the illustration. Note that the down-slope upstand is bent at a 110-degree angle to the slope. No cutting is needed or appropriate; the flashing is formed with folds, bread-pan style.

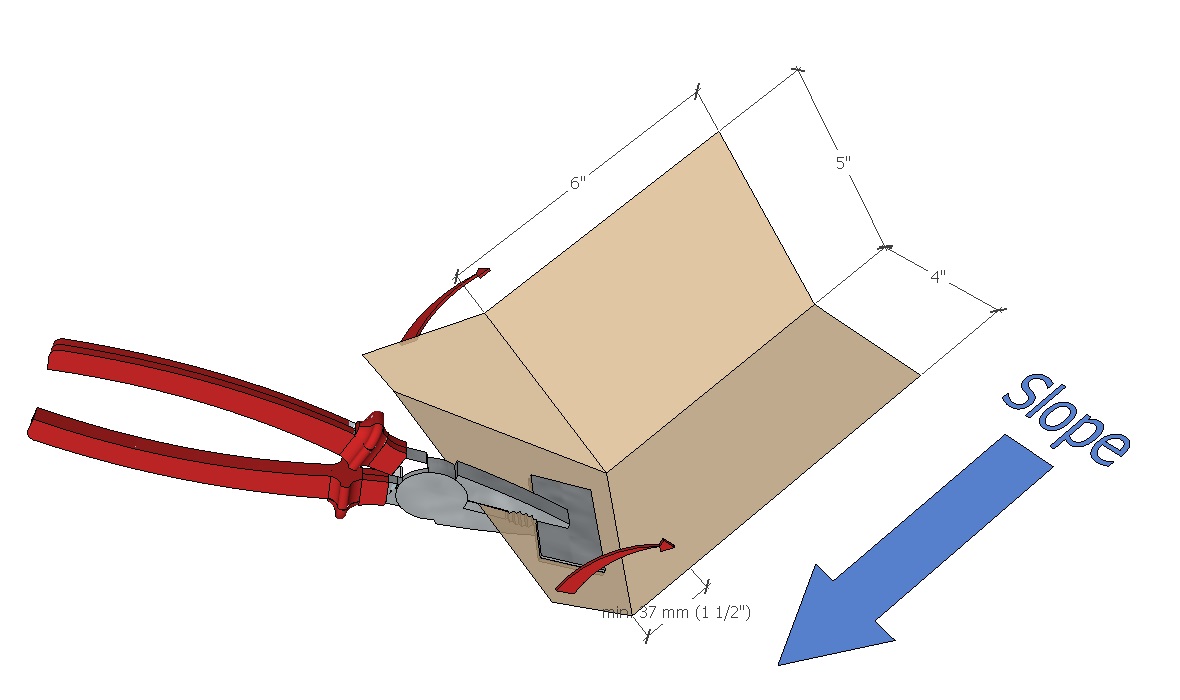

- (2) Step 2

- Fold the bottom end of the flashing as illustrated, so that the bottom upstand aligns with the vertical bread-pan fold made in the next step.

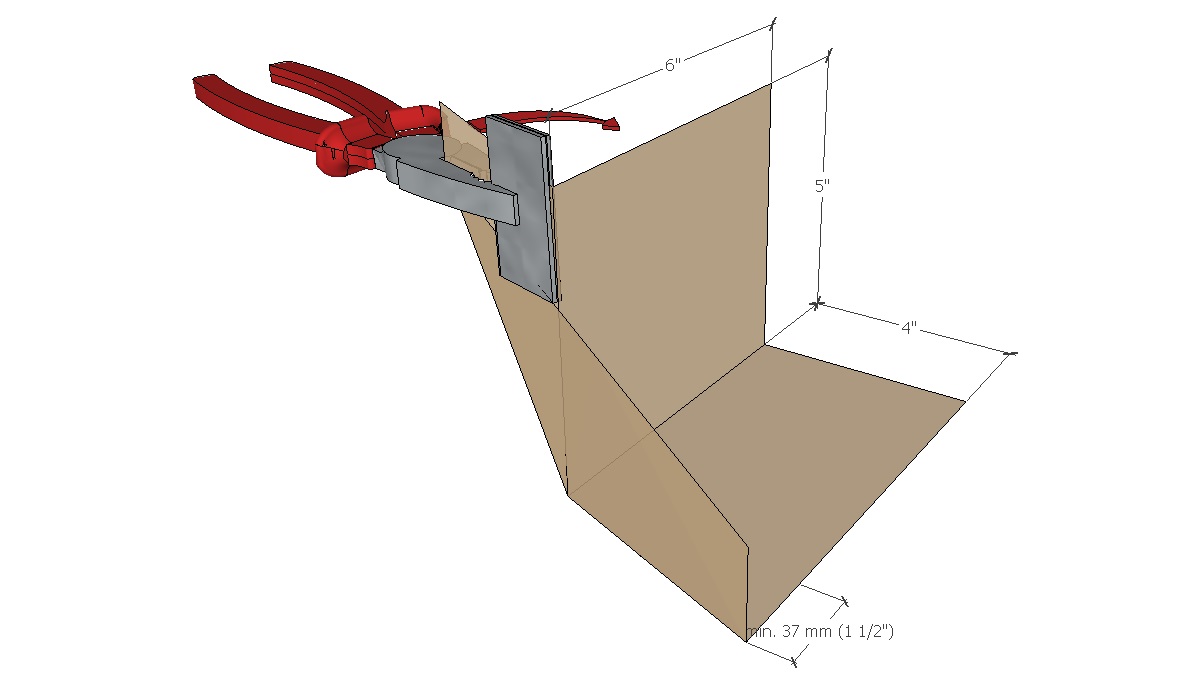

- (3) Step 3

- Fold the back flap around and behind the main upstand, bread-pan style.

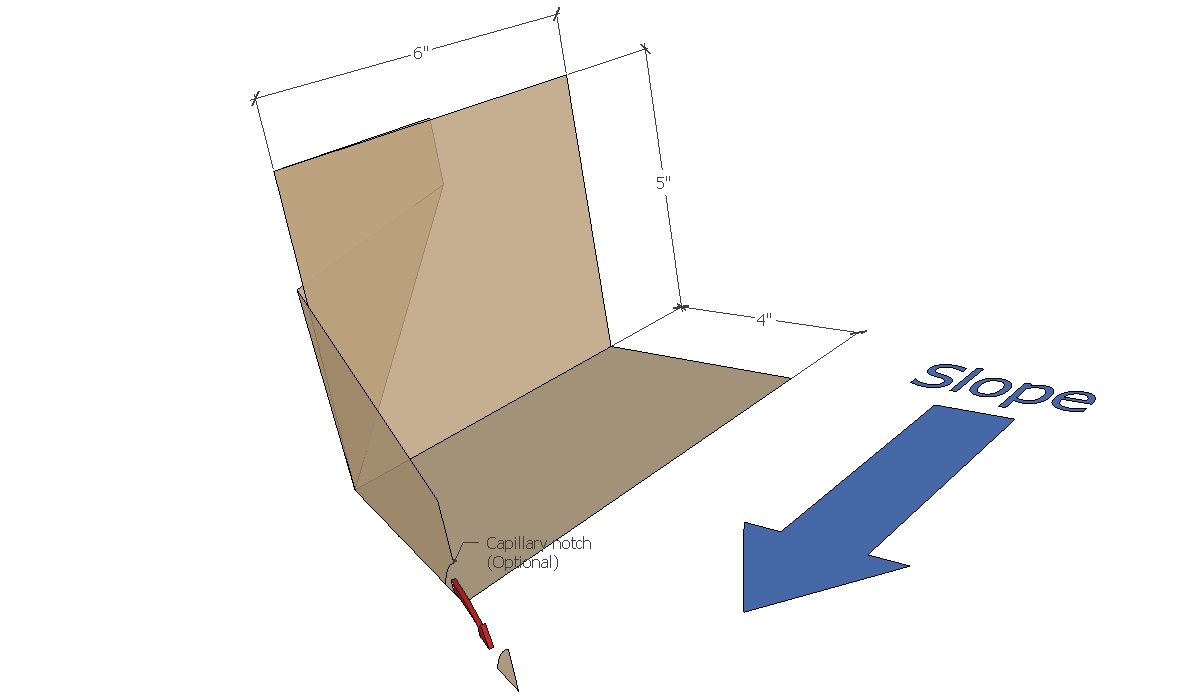

- (4) Step 4

- If required or desirable, cut a capillary notch in the bottom upstand (illustrated), and trim the upstand to suit the aesthetics of the roof.

2 RELATED WORK BY OTHERS

- None

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

Standard for Asphalt Shingle Systems