Difference between revisions of "SBS Structural Planter"

Difference between revisions of "SBS Structural Planter"

| Line 1: | Line 1: | ||

{{Template:RPM Info}} | {{Template:RPM Info}} | ||

| − | + | <hr> | |

{| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | {| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | ||

| colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span style="color:#6495ed">'''blue-linked'''</span></big> | | colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span style="color:#6495ed">'''blue-linked'''</span></big> | ||

| Line 28: | Line 28: | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

;(1) '''Primer''': Application method and coverage rate as approved by Primary Membrane Manufacturer. | ;(1) '''Primer''': Application method and coverage rate as approved by Primary Membrane Manufacturer. | ||

| − | ;(2) [[ | + | ;(2) [[SBS Roof Systems Standard#SBSBASE|'''Primary Roof Membrane''']]: Modified Bituminous base and cap sheet membranes installed as per manufacturer's published application specifications. |

| − | ;(3) [[ | + | ;(3) [[SBS Roof Systems Standard#SBSPRECURB|'''Pre-Curb (Start-Up Curb) Membrane Flashing''']]: Modified Bituminous base and cap sheet membrane flashing installed as per manufacturer's published application specifications. |

| − | ;(4) | + | ;(4) [[SBS Roof Systems Standard#SBSLIQUIDDETAILS|'''Proprietary Liquid Membrane Flashing''']]: RoofStar Guarantee Program accepted Liquid Membrane Flashing System(s) or hot melt SBS modified bitumen. (NOTE: Refer to [[Flexible Membrane Roofing Systems: Liquid Membrane Flashing Systems|'''Liquid Membrane Flashing Systems''']] in the Accepted Materials section of this Manual). Install as per Manufacturer's published instructions. |

| − | ;(5) [[ | + | ;(5) [[SBS Roof Systems Standard#SBS-STRIPPING|'''Inside Planter Wall Membrane Flashing''']]: Adhered according to manufacturer's specifications using cold adhesive, self-adhered or torch-applied membrane. Torching directly to wood surfaces is not permitted. Carry membrane flashing plies to reglet termination near top of planter wall (stagger membrane seal minimum 300mm (6"). |

| − | ;(6) [[ | + | ;(6) [[SBS Roof Systems Standard#METALCAP-SBS|'''Reglet - Metal Counter Flashing''']]: As required by the ''RoofStar Guarantee Standards''. Note that a coping flashing may be paired with the reglet flashing, as illustrated. |

;(7) '''Plaza Deck / Planter Interior Assembly''': Extruded polystyrene insulation and filter mat over primary roof membranes. Concrete pavers placed above pre-curb membrane flashing height, on proprietary pedestals. Note: membrane flashing is not permitted above pre-curb membrane flashing on plaza deck side of planter walls. | ;(7) '''Plaza Deck / Planter Interior Assembly''': Extruded polystyrene insulation and filter mat over primary roof membranes. Concrete pavers placed above pre-curb membrane flashing height, on proprietary pedestals. Note: membrane flashing is not permitted above pre-curb membrane flashing on plaza deck side of planter walls. | ||

| Line 38: | Line 38: | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[ | + | ;(A) [[SBS Roof Systems Standard#SBSDECKS|'''Acceptable Supporting Deck Structure''']]: Concrete slab shown. Each planter area must have a drain through the roof deck. |

;(B) '''Pre-Curb''': Minimum of 100mm (4") in height above concrete deck, smooth dry and clean. | ;(B) '''Pre-Curb''': Minimum of 100mm (4") in height above concrete deck, smooth dry and clean. | ||

;(C) '''Cast over Concrete Planter Wall''': Form on top of membrane sealed Pre-curbs or Start-up curbs. | ;(C) '''Cast over Concrete Planter Wall''': Form on top of membrane sealed Pre-curbs or Start-up curbs. | ||

;(D) '''Re-Bar''': Placed at centre of Pre-curb. | ;(D) '''Re-Bar''': Placed at centre of Pre-curb. | ||

| − | ;(E) [[ | + | ;(E) [[SBS Roof Systems Standard#METALCAP-SBS|'''Reglet''']]: Premanufactured purpose-made reglet cast in concrete wall or saw-cut. |

;(F) '''Alternate Termination''': Horizontal Reglet alternative to pre-manufactured purpose-made reglet, cast in concrete wall or saw-cut on vertical surface of inside planter walls. | ;(F) '''Alternate Termination''': Horizontal Reglet alternative to pre-manufactured purpose-made reglet, cast in concrete wall or saw-cut on vertical surface of inside planter walls. | ||

</div><!-- COL-6-MD --> | </div><!-- COL-6-MD --> | ||

| Line 54: | Line 54: | ||

| − | [[ | + | [[SBS Roof Systems Standard|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''RoofStar Guarantee Standards for SBS Modified Bitumen Roof Assemblies'']] |

| − | |||

| − | |||

| − | [[ | + | [[SBS Roof System Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''SBS Modified Bitumen Construction Details'']] |

Revision as of 16:57, 27 August 2021

| RoofStar Guarantee Standards are blue-linked |

SBS Details

1 WORK INCLUDED

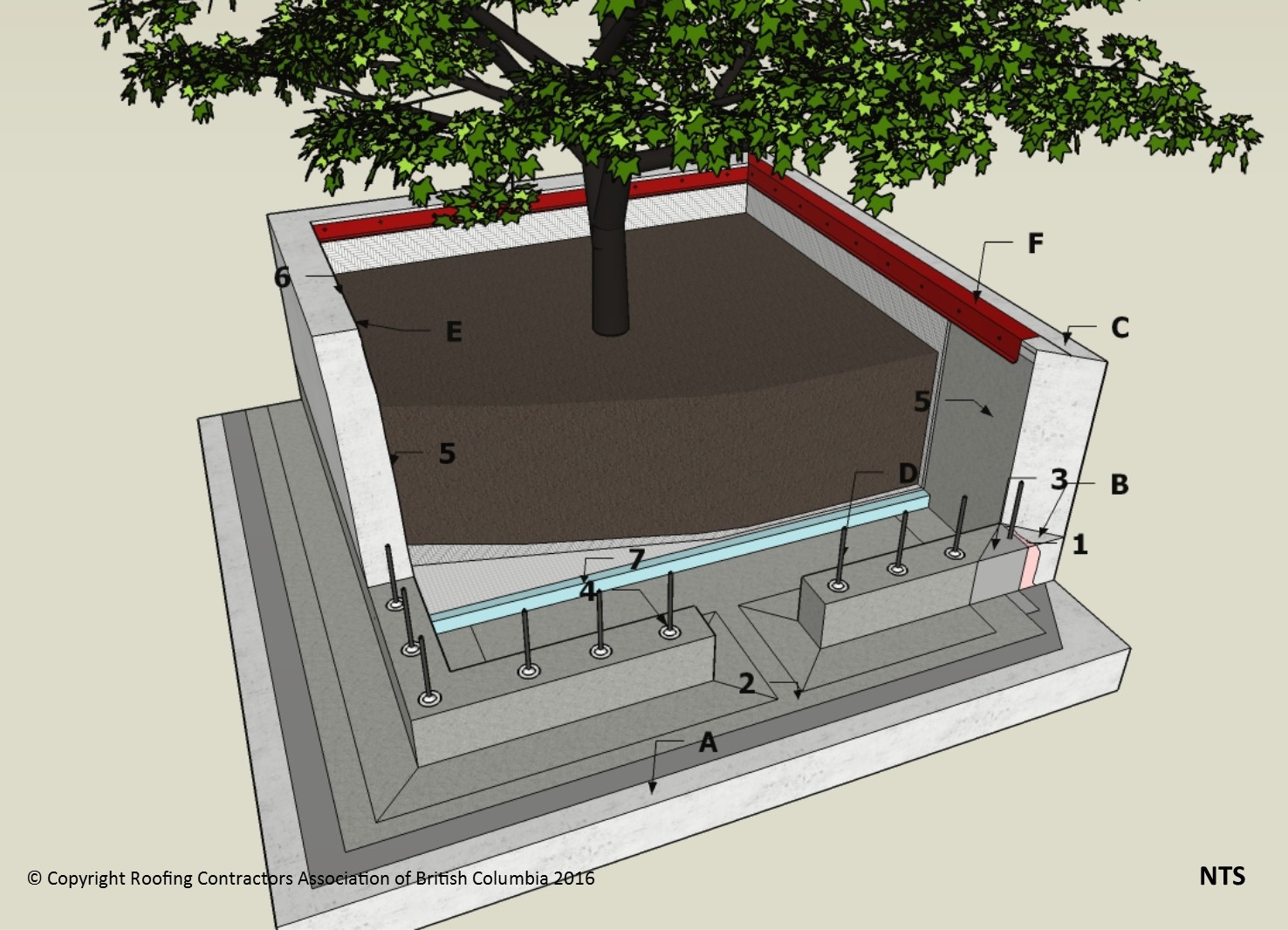

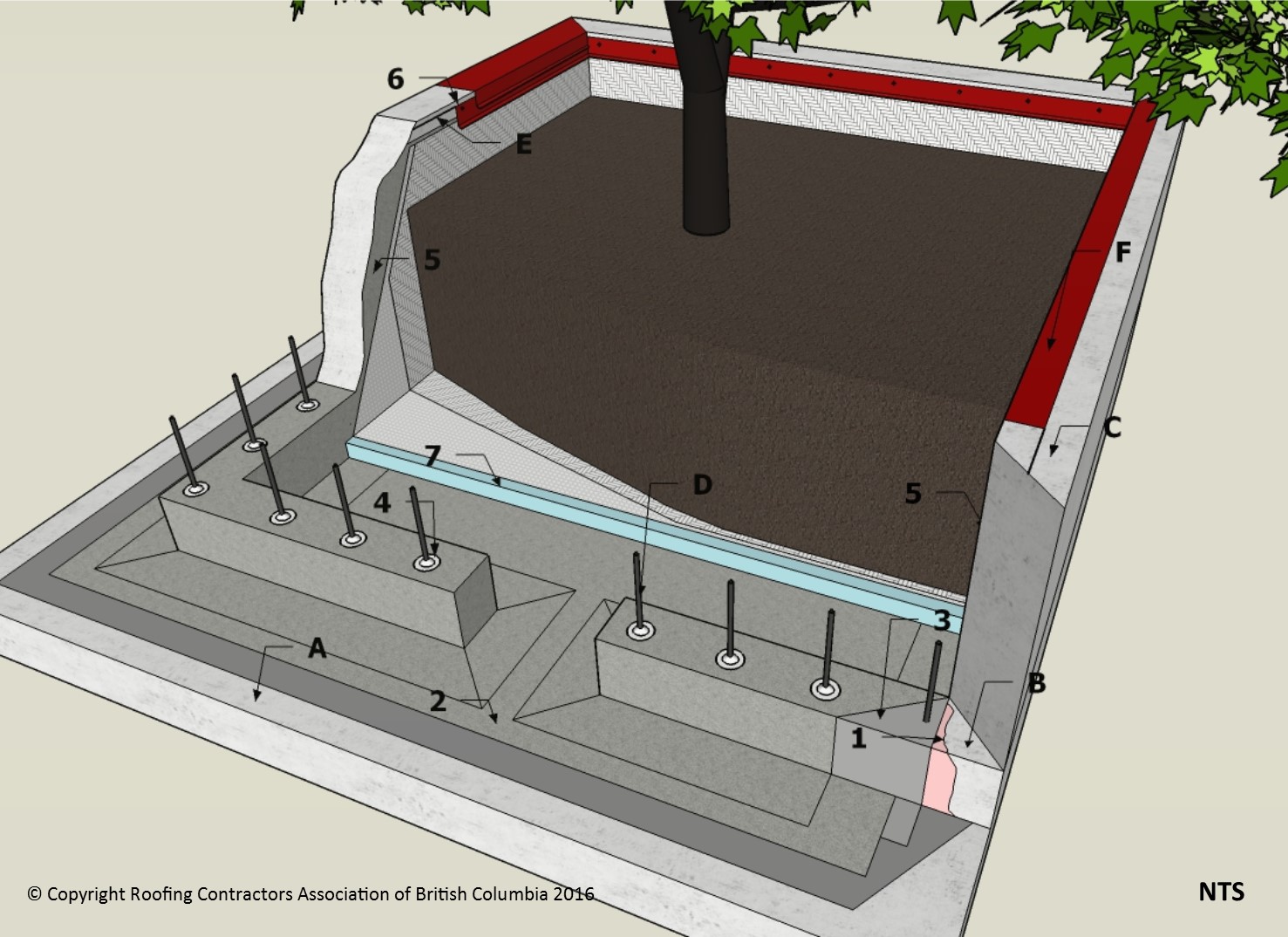

- (1) Primer

- Application method and coverage rate as approved by Primary Membrane Manufacturer.

- (2) Primary Roof Membrane

- Modified Bituminous base and cap sheet membranes installed as per manufacturer's published application specifications.

- (3) Pre-Curb (Start-Up Curb) Membrane Flashing

- Modified Bituminous base and cap sheet membrane flashing installed as per manufacturer's published application specifications.

- (4) Proprietary Liquid Membrane Flashing

- RoofStar Guarantee Program accepted Liquid Membrane Flashing System(s) or hot melt SBS modified bitumen. (NOTE: Refer to Liquid Membrane Flashing Systems in the Accepted Materials section of this Manual). Install as per Manufacturer's published instructions.

- (5) Inside Planter Wall Membrane Flashing

- Adhered according to manufacturer's specifications using cold adhesive, self-adhered or torch-applied membrane. Torching directly to wood surfaces is not permitted. Carry membrane flashing plies to reglet termination near top of planter wall (stagger membrane seal minimum 300mm (6").

- (6) Reglet - Metal Counter Flashing

- As required by the RoofStar Guarantee Standards. Note that a coping flashing may be paired with the reglet flashing, as illustrated.

- (7) Plaza Deck / Planter Interior Assembly

- Extruded polystyrene insulation and filter mat over primary roof membranes. Concrete pavers placed above pre-curb membrane flashing height, on proprietary pedestals. Note: membrane flashing is not permitted above pre-curb membrane flashing on plaza deck side of planter walls.

2 RELATED WORK BY OTHERS

- (A) Acceptable Supporting Deck Structure

- Concrete slab shown. Each planter area must have a drain through the roof deck.

- (B) Pre-Curb

- Minimum of 100mm (4") in height above concrete deck, smooth dry and clean.

- (C) Cast over Concrete Planter Wall

- Form on top of membrane sealed Pre-curbs or Start-up curbs.

- (D) Re-Bar

- Placed at centre of Pre-curb.

- (E) Reglet

- Premanufactured purpose-made reglet cast in concrete wall or saw-cut.

- (F) Alternate Termination

- Horizontal Reglet alternative to pre-manufactured purpose-made reglet, cast in concrete wall or saw-cut on vertical surface of inside planter walls.

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

Back to RoofStar Guarantee Standards for SBS Modified Bitumen Roof Assemblies