Difference between revisions of "Asphalt Shingles - Diverter Flashing"

Difference between revisions of "Asphalt Shingles - Diverter Flashing"

(→WORK INCLUDED) |

|||

| Line 25: | Line 25: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | ;(1) [[Asphalt Shingle Systems | + | ;(1) [[Asphalt Shingle Systems Standard#AShDIVERTER|'''Step 1''']]: Use a standard 225 mm (9”) long step flashing and scribe the fold lines as shown on the illustration. Note that the down-slope upstand is bent at a 110-degree angle to the slope. No cutting is needed or appropriate; the flashing is formed with folds, bread-pan style. |

;(2) [[Asphalt Shingle Systems Standard#AShDIVERTER|'''Step 2''']]: Fold the bottom end of the flashing as illustrated, so that the bottom upstand aligns with the vertical bread-pan fold made in the next step. | ;(2) [[Asphalt Shingle Systems Standard#AShDIVERTER|'''Step 2''']]: Fold the bottom end of the flashing as illustrated, so that the bottom upstand aligns with the vertical bread-pan fold made in the next step. | ||

;(3) [[Asphalt Shingle Systems Standard#AShDIVERTER|'''Step 3''']]: Fold the back flap around and behind the main upstand, bread-pan style. | ;(3) [[Asphalt Shingle Systems Standard#AShDIVERTER|'''Step 3''']]: Fold the back flap around and behind the main upstand, bread-pan style. | ||

Revision as of 15:48, 31 August 2021

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the requirements of the Standard they represent. Unless otherwise required by the Standard, dimensions, the selection of materials and their application remains the responsibility of the Design Authority. The full text of the referenced requirements in the Standard may be read by using the blue hyperlinks | |

Asphalt Shingle Details

1 WORK INCLUDED

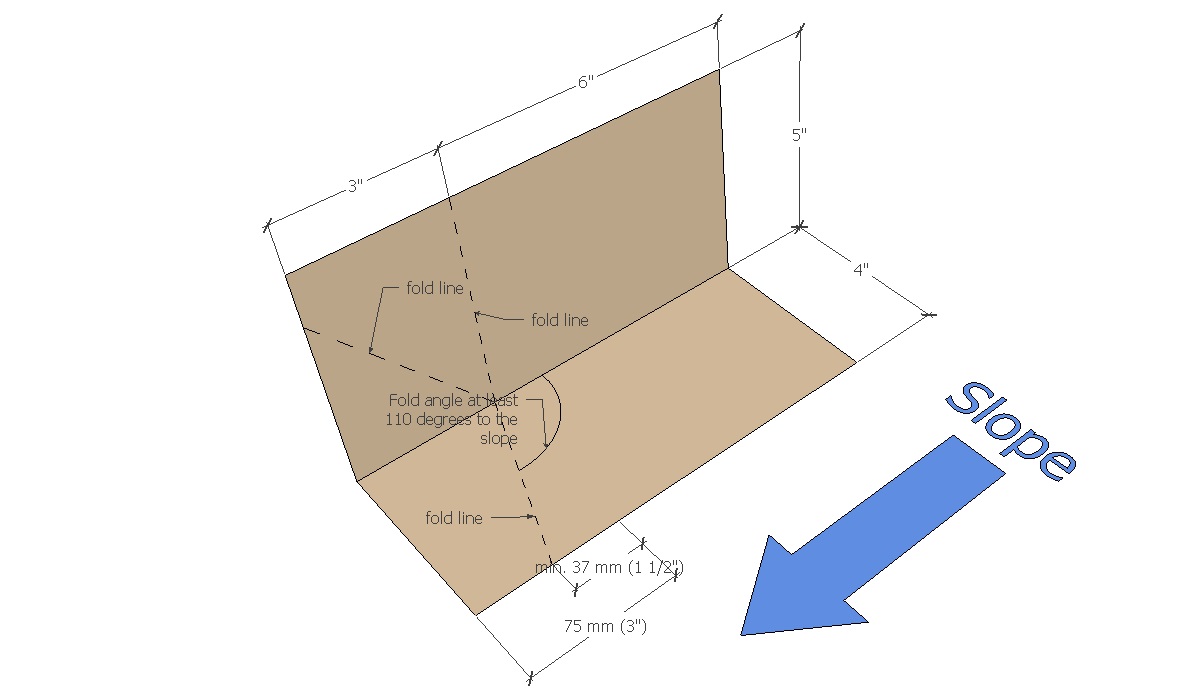

- (1) Step 1

- Use a standard 225 mm (9”) long step flashing and scribe the fold lines as shown on the illustration. Note that the down-slope upstand is bent at a 110-degree angle to the slope. No cutting is needed or appropriate; the flashing is formed with folds, bread-pan style.

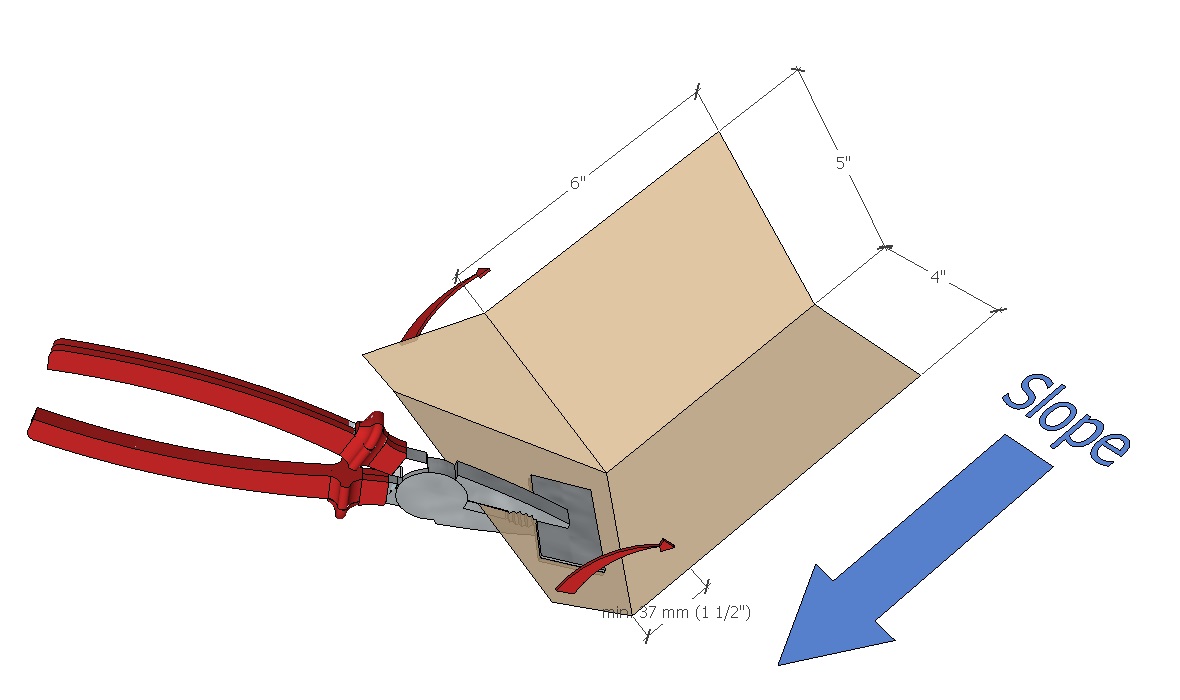

- (2) Step 2

- Fold the bottom end of the flashing as illustrated, so that the bottom upstand aligns with the vertical bread-pan fold made in the next step.

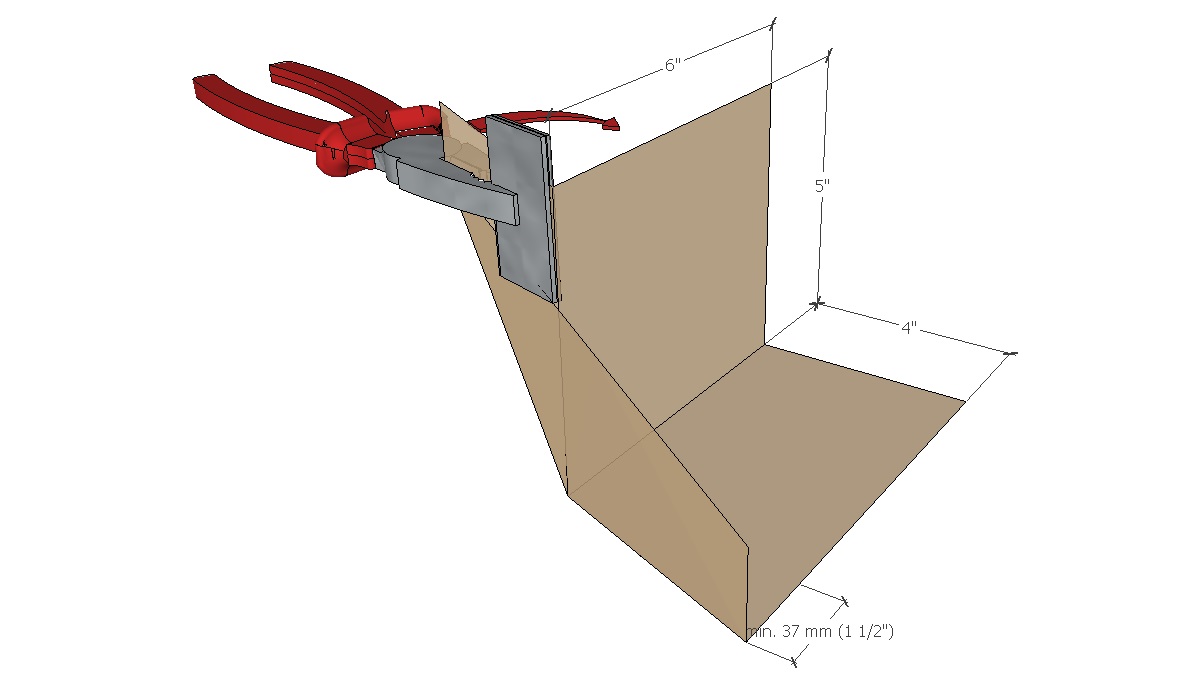

- (3) Step 3

- Fold the back flap around and behind the main upstand, bread-pan style.

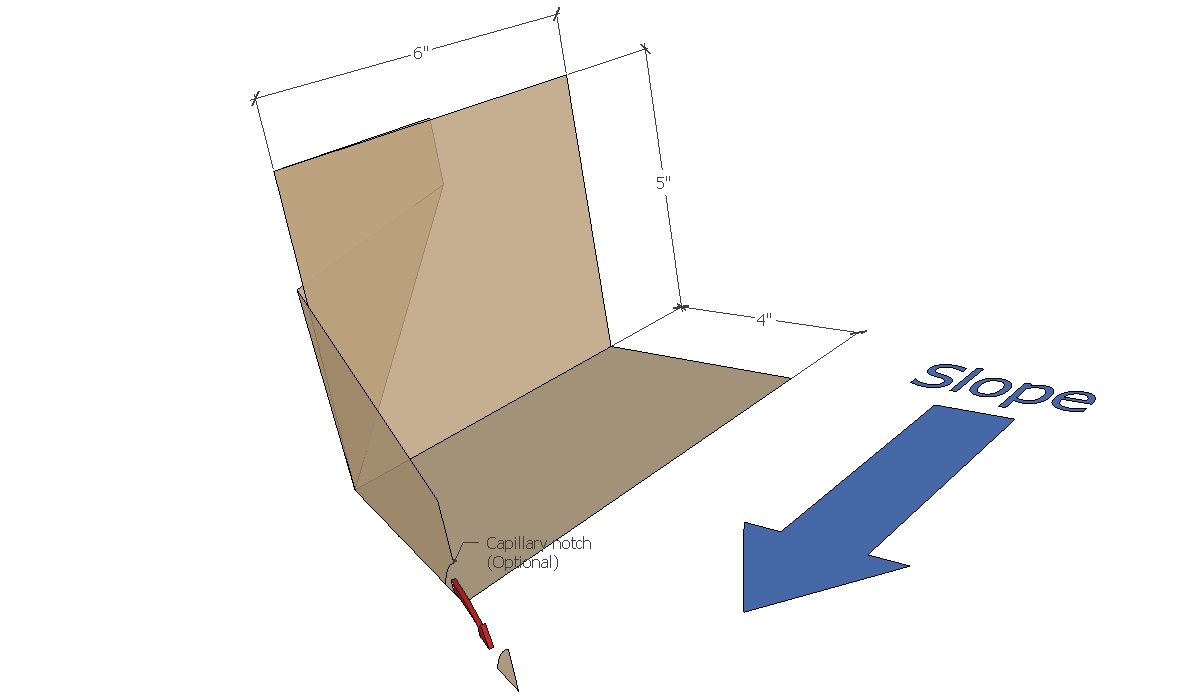

- (4) Step 4

- If required or desirable, cut a capillary notch in the bottom upstand (illustrated), and trim the upstand to suit the aesthetics of the roof.

2 RELATED WORK BY OTHERS

- None

NOTE: See the Standard for additional requirements.

Back to "SBS" Roof System Details

© RCABC 2026

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.