Difference between revisions of "TS Details:E4.7.9 (Slate - Hips)"

Difference between revisions of "TS Details:E4.7.9 (Slate - Hips)"

| Line 12: | Line 12: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

<div style="text-align:center; vertical-align:center"> | <div style="text-align:center; vertical-align:center"> | ||

| − | [[File:7.4.1.2.6.jpg|class=img-responsive]] | + | [[File:7.4.1.2.6.jpg| link=http://rpm.rcabc.org/images/9/93/7.4.1.2.6.jpg | class=img-responsive]] |

| − | [[File:7.4.1.2.7.jpg|class=img-responsive]] | + | [[File:7.4.1.2.7.jpg| link=http://rpm.rcabc.org/images/6/62/7.4.1.2.7.jpg | class=img-responsive]] |

</div> | </div> | ||

</div><!-- COL-MD-6 --> | </div><!-- COL-MD-6 --> | ||

Revision as of 21:33, 31 August 2021

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the requirements of the Standard they represent. Unless otherwise required by the Standard, dimensions, the selection of materials and their application remains the responsibility of the Design Authority. The full text of the referenced requirements in the Standard may be read by using the blue hyperlinks | |

Hips on a slate roof can be either mitred, saddled or have a metal flashing.

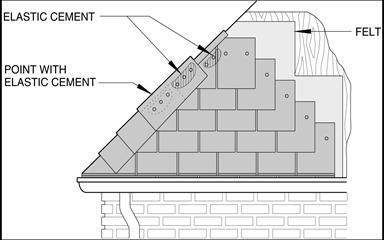

Saddled hips require a lathe nailer on both sides thick enough to support the hip tiles from the field tiles. The width should allow nailing and keep a 75 mm (3") lap over field tiles. Nail heads should be covered with elastic cement between successive tiles.

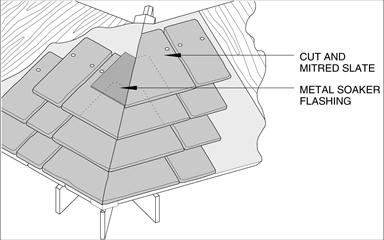

On mitred hips, field slates are cut flush at the apex to match slates on the other side. The unexposed portion of these slates is covered with a metal flashing which should extend 50 mm up from the tiles being covered.

NOTE: See the Standard for additional requirements.

© RCABC 2026

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.