Difference between revisions of "Asphalt Shingles - Diverter Flashing"

Difference between revisions of "Asphalt Shingles - Diverter Flashing"

m (James Klassen moved page Asphalt Shingles Diverter Flashing to Asphalt Shingles - Diverter Flashing) |

|||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{Template:RPM Info}} | {{Template:RPM Info}} | ||

| + | |||

| + | {{DISPLAYTITLE:<span style="position: absolute; clip: rect(1px 1px 1px 1px); clip: rect(1px, 1px, 1px, 1px);">{{FULLPAGENAME}}</span>}} | ||

| + | __NOTOC__ | ||

| + | |||

| + | <big><big>Division D - Construction Details</big></big> | ||

<hr> | <hr> | ||

| − | + | <big><big><big><big><big>Asphalt Shingles | Diverter Flashing ([[Asphalt_Shingle_Systems_Standard#10.1.4.2. Eave and Rake Edges | Article 10.1.4.2.]])</big></big></big></big></big> | |

| − | + | {{Template:Construction Details Header}} | |

| − | | | ||

| − | |||

| − | |||

<div class="panel panel-success"> | <div class="panel panel-success"> | ||

<div class="panel-heading"><big>'''Asphalt Shingle Details'''</big></div> | <div class="panel-heading"><big>'''Asphalt Shingle Details'''</big></div> | ||

Latest revision as of 14:28, 30 June 2022

Division D - Construction Details

Asphalt Shingles | Diverter Flashing ( Article 10.1.4.2.)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

Asphalt Shingle Details

1 WORK INCLUDED

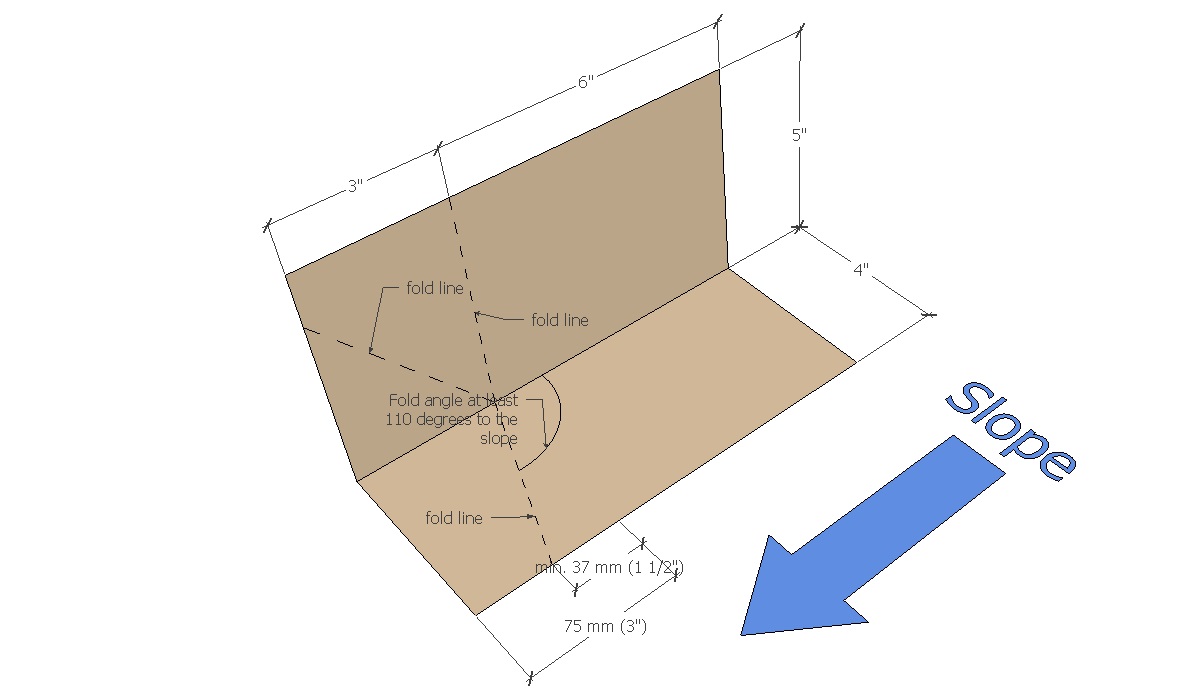

- (1) Step 1

- Use a standard 225 mm (9”) long step flashing and scribe the fold lines as shown on the illustration. Note that the down-slope upstand is bent at a 110-degree angle to the slope. No cutting is needed or appropriate; the flashing is formed with folds, bread-pan style.

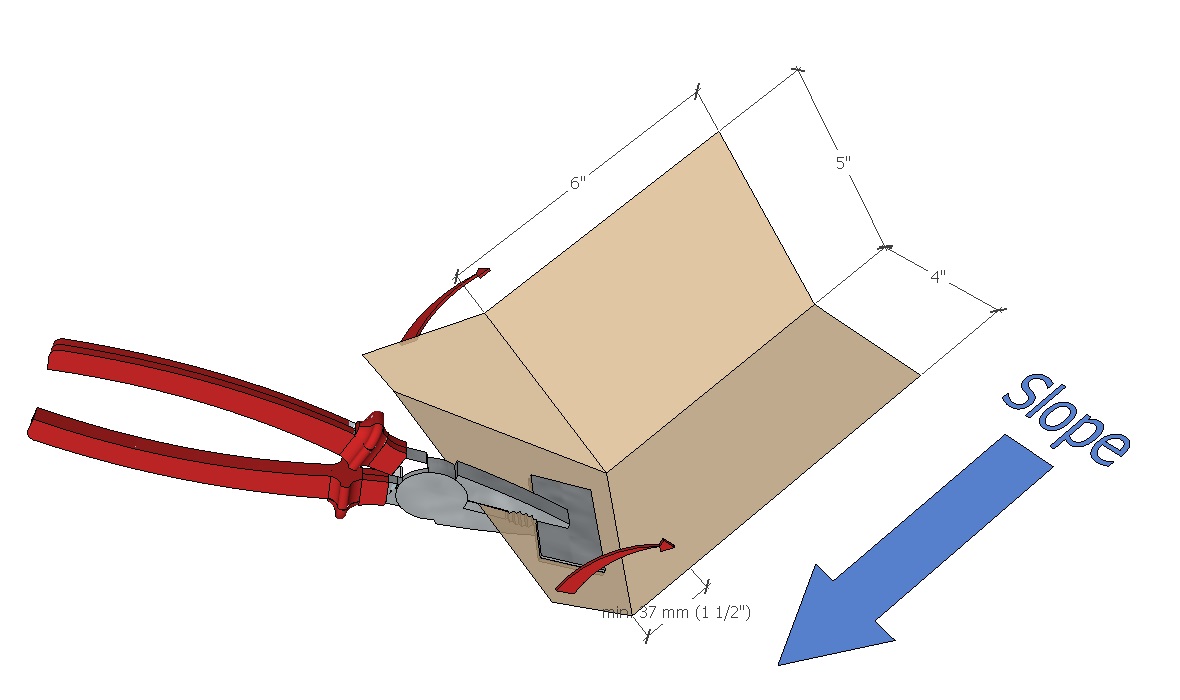

- (2) Step 2

- Fold the bottom end of the flashing as illustrated, so that the bottom upstand aligns with the vertical bread-pan fold made in the next step.

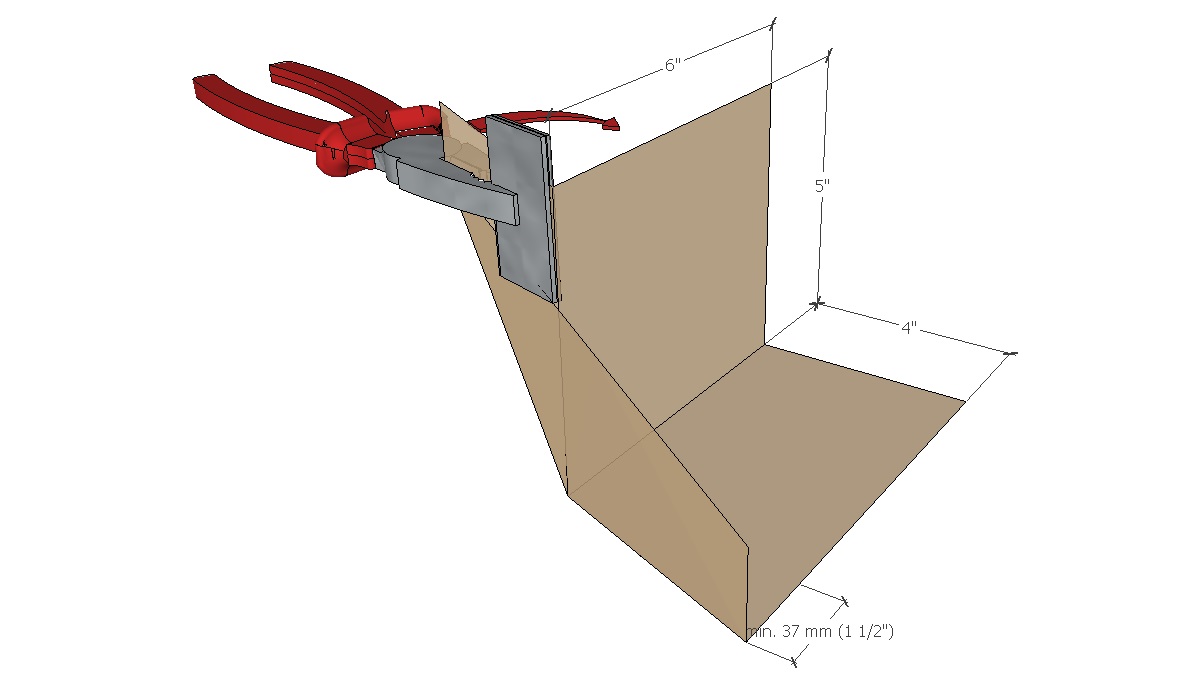

- (3) Step 3

- Fold the back flap around and behind the main upstand, bread-pan style.

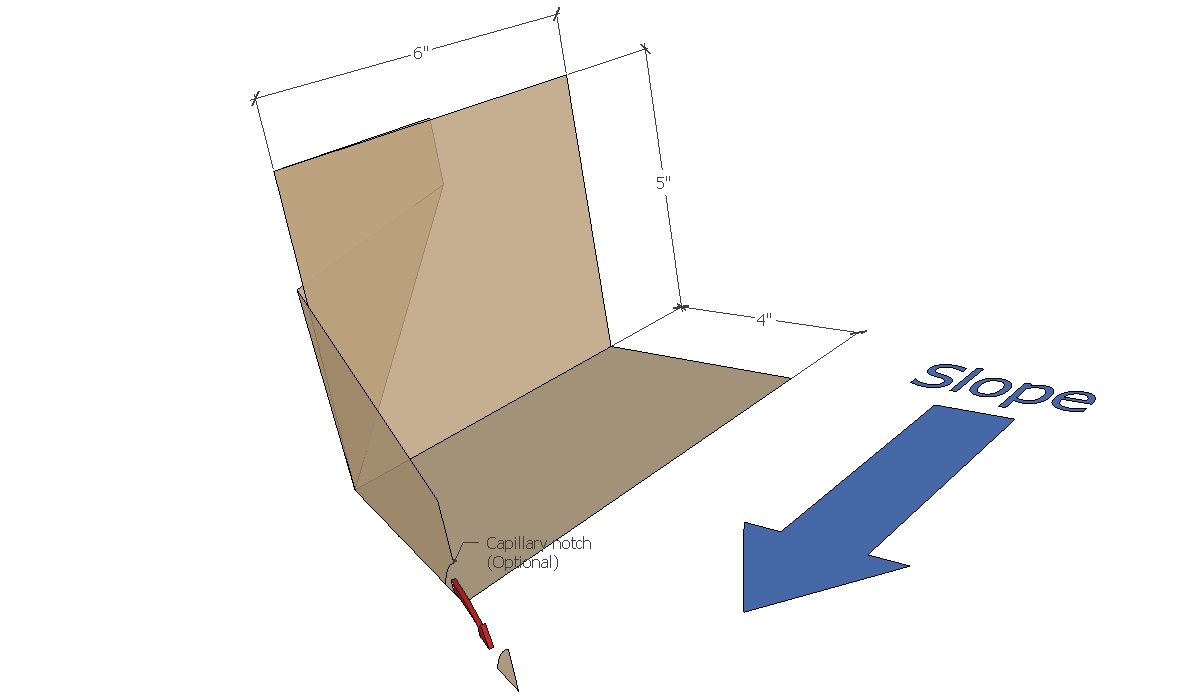

- (4) Step 4

- If required or desirable, cut a capillary notch in the bottom upstand (illustrated), and trim the upstand to suit the aesthetics of the roof.

2 RELATED WORK BY OTHERS

- None

NOTE: See the Standard for additional requirements.

Back to Asphalt Shingle System Details

© RCABC 2024

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.