Difference between revisions of "Asphalt Shingles - Air and Vapour Controls"

Difference between revisions of "Asphalt Shingles - Air and Vapour Controls"

m (James Klassen moved page Asphalt Shingles Air and Vapour Controls to Asphalt Shingles - Air and Vapour Controls) |

|||

| (4 intermediate revisions by the same user not shown) | |||

| Line 6: | Line 6: | ||

<big><big>Division D - Construction Details</big></big> | <big><big>Division D - Construction Details</big></big> | ||

<hr> | <hr> | ||

| − | <big><big><big><big><big> | + | <big><big><big><big><big>Asphalt Shingles | Air and Vapour Controls (Field) ([[Asphalt_Shingle_Systems_Standard#6.3.2.1._Continuity_and_Support | Article 6.3.2.1.]])</big></big></big></big></big> |

| − | { | + | {{Template:Construction Details Header}} |

| − | |||

| − | |||

| − | |||

| − | |||

<div class="panel panel-success"> | <div class="panel panel-success"> | ||

<div class="panel-heading"><big>'''"All Systems" Details'''</big></div> | <div class="panel-heading"><big>'''"All Systems" Details'''</big></div> | ||

| Line 17: | Line 13: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

<div style="text-align:center; vertical-align:center"> | <div style="text-align:center; vertical-align:center"> | ||

| − | [[File: | + | [[File:Figure 6.3.1-1.jpg|class=img-responsive | link=https://rpm.rcabc.org/images/5/54/Figure_6.3.1-1.jpg]] |

<br> | <br> | ||

<div class="col-md-8"> | <div class="col-md-8"> | ||

| − | [[File: | + | [[File:Figure 6.3.1-2.jpg|class=img-responsive | link=https://rpm.rcabc.org/images/d/d0/Figure_6.3.1-2.jpg]] |

</div> | </div> | ||

</div> | </div> | ||

| Line 38: | Line 34: | ||

;(2) '''Air or Vapour Controls''': Self-adhering membrane (typical). | ;(2) '''Air or Vapour Controls''': Self-adhering membrane (typical). | ||

;(3) '''Metal Support''': For fully or intermittently unsupported side or end laps. Use pre-finished galvanized steel (min. 24 Ga.), fabricated at least 100 mm (4”) wider than membrane overlaps, and secured with compatible flat-head fasteners (two fasteners per flute, or as otherwise specified). | ;(3) '''Metal Support''': For fully or intermittently unsupported side or end laps. Use pre-finished galvanized steel (min. 24 Ga.), fabricated at least 100 mm (4”) wider than membrane overlaps, and secured with compatible flat-head fasteners (two fasteners per flute, or as otherwise specified). | ||

| − | ;(4) '''Long edges''':Centre membrane runs along top flutes of steel deck (applicable when no deck overlay is specified and installed). | + | ;(4) '''Long edges (side laps)''':Centre membrane runs along top flutes of steel deck (applicable when no deck overlay is specified and installed). Overlap membrane side laps at least 50 mm (2”), or as specified by the membrane manufacturer (whichever is greater). Side laps must be fully supported by the roof deck or a metal support. |

;(5) '''End laps''':Overlap the roll ends at least 100 mm (4”), or as specified by the membrane manufacturer (whichever is greater). End laps must be fully supported by the roof deck or a metal support. | ;(5) '''End laps''':Overlap the roll ends at least 100 mm (4”), or as specified by the membrane manufacturer (whichever is greater). End laps must be fully supported by the roof deck or a metal support. | ||

| − | |||

<hr> | <hr> | ||

Latest revision as of 14:29, 30 June 2022

Division D - Construction Details

Asphalt Shingles | Air and Vapour Controls (Field) ( Article 6.3.2.1.)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

"All Systems" Details

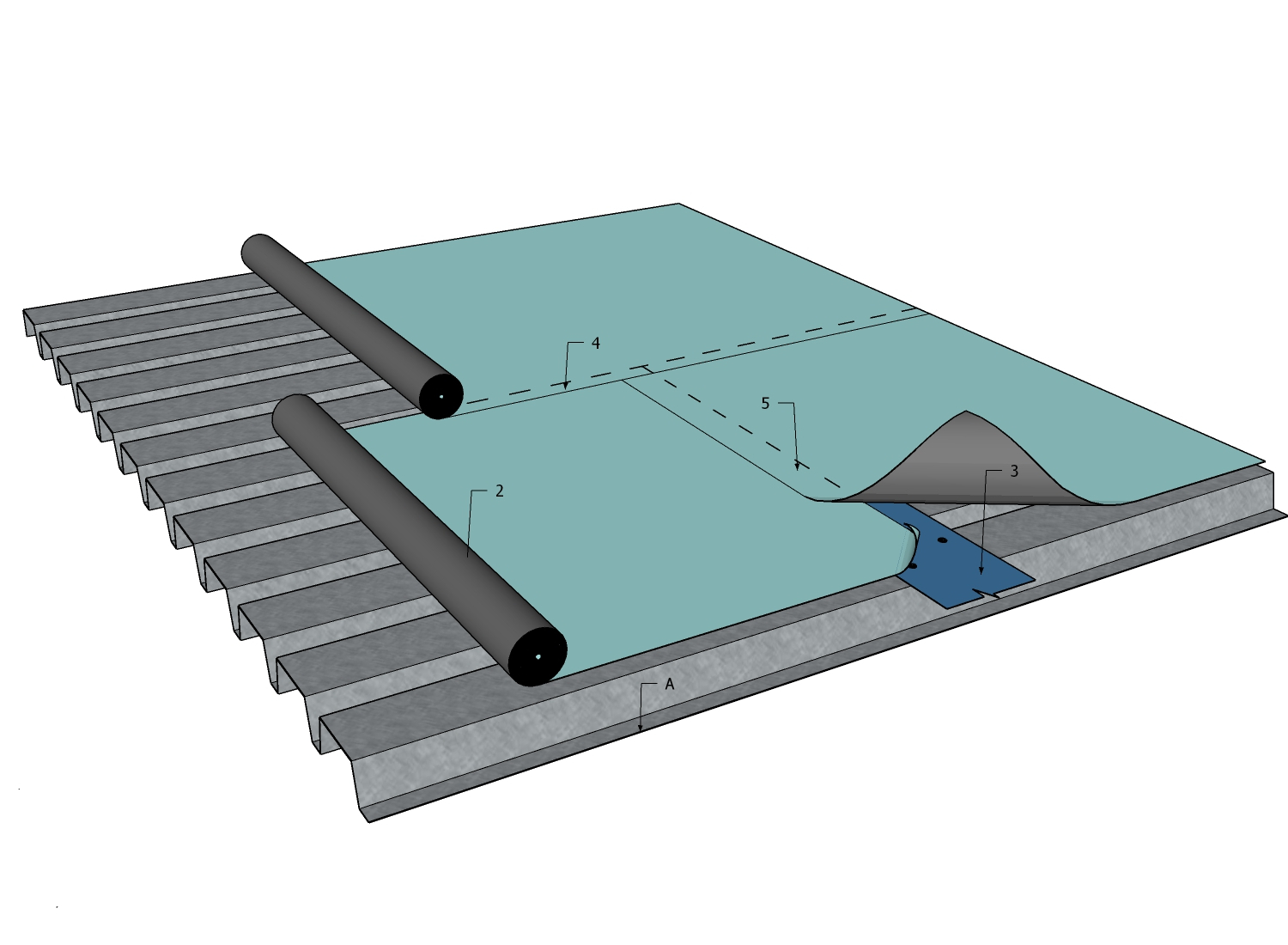

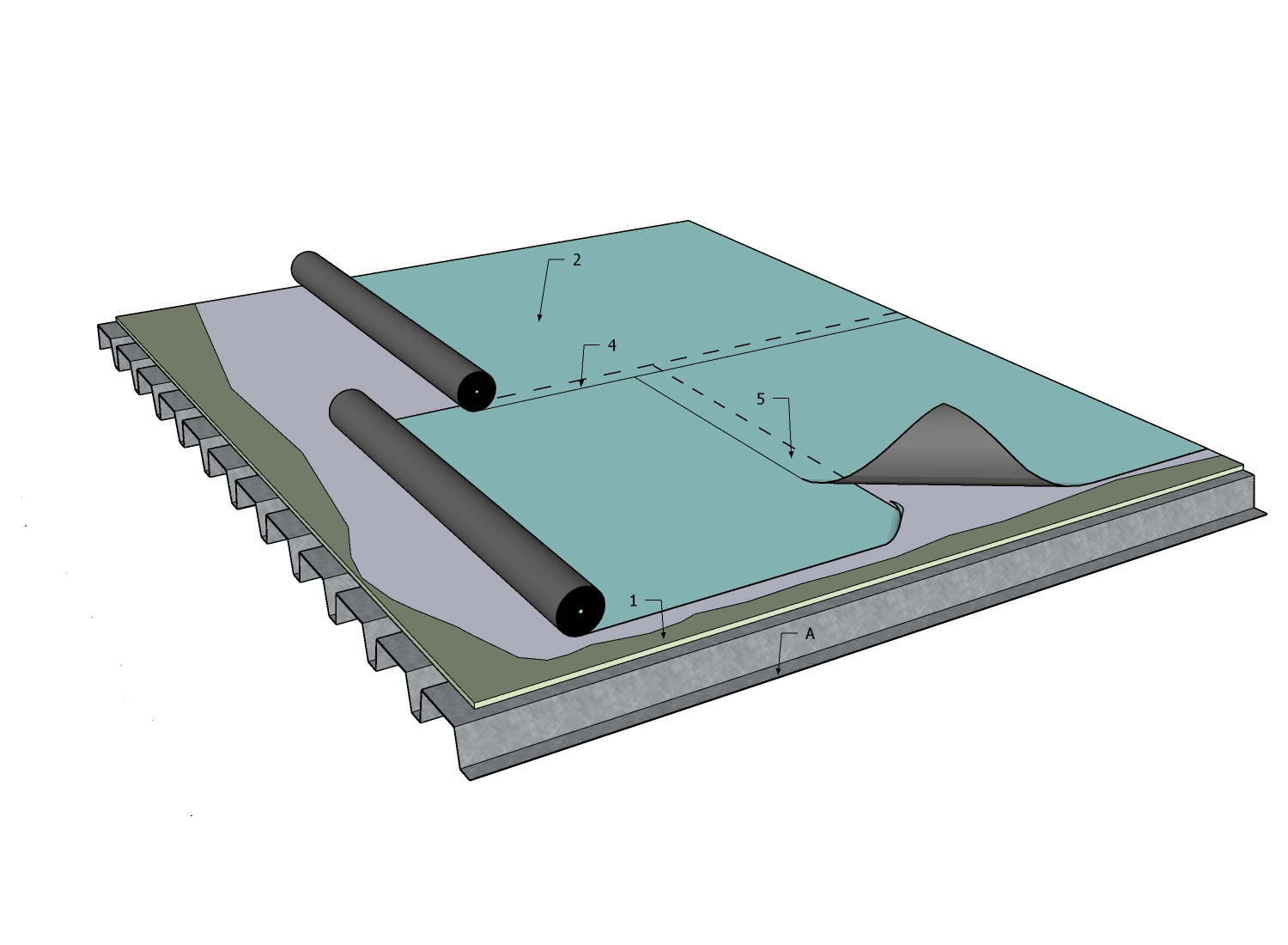

1 WORK INCLUDED

- (1) Supporting Deck Overlay

- Recommended over steel decks, to provide continuous support for membrane control layers (this fulfills the requirement for continuity, British Columbia Building Code, Div. B, 5.4.1.2 (3)).

- (2) Air or Vapour Controls

- Self-adhering membrane (typical).

- (3) Metal Support

- For fully or intermittently unsupported side or end laps. Use pre-finished galvanized steel (min. 24 Ga.), fabricated at least 100 mm (4”) wider than membrane overlaps, and secured with compatible flat-head fasteners (two fasteners per flute, or as otherwise specified).

- (4) Long edges (side laps)

- Centre membrane runs along top flutes of steel deck (applicable when no deck overlay is specified and installed). Overlap membrane side laps at least 50 mm (2”), or as specified by the membrane manufacturer (whichever is greater). Side laps must be fully supported by the roof deck or a metal support.

- (5) End laps

- Overlap the roll ends at least 100 mm (4”), or as specified by the membrane manufacturer (whichever is greater). End laps must be fully supported by the roof deck or a metal support.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

NOTE: See the Standard for additional requirements.

Back to Asphalt Shingle System Details

© RCABC 2026

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.