Difference between revisions of "SBS Equipment Sleeper"

Difference between revisions of "SBS Equipment Sleeper"

(→RELATED WORK BY OTHERS) |

(→RELATED WORK BY OTHERS) |

||

| Line 29: | Line 29: | ||

| − | [[Section:D. Application: Low Slope Roofs|<i class="fa fa-chevron-circle-left fa | + | [[Section:D. Application: Low Slope Roofs|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''SBS Application'']] |

| − | [[SBS Construction Details|<i class="fa fa-chevron-circle-left fa | + | [[SBS Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''SBS Construction Details'']] |

| − | [[Section:G. Construction Details|<i class="fa fa-chevron-circle-left fa | + | [[Section:G. Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] |

Revision as of 17:50, 8 August 2016

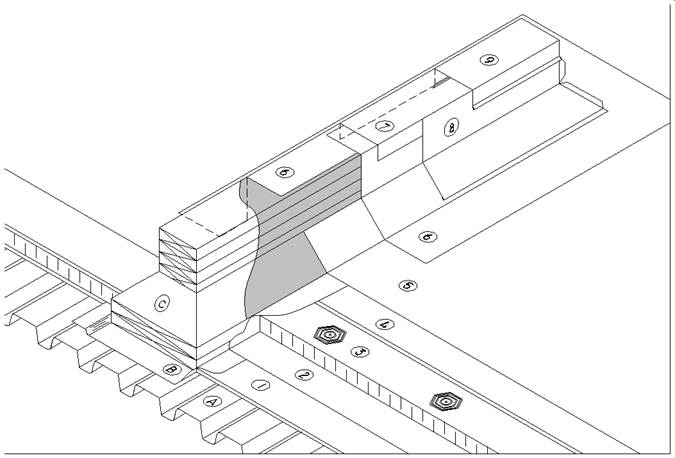

1 WORK INCLUDED

- (1) Gypsum Deck Overlay

- If required by design authority.

- (2) Vapour Retarder

- If required by design authority.

- (3) Insulation

- See available insulation products in the Accepted Materials section of this Manual.

- (4) Insulation Overlay Board

- As required.

- (5) Primary Membrane and Membrane Protection

- (6) Membrane Flashing

- Lap one ply from each side over top of sleeper (C) and mechanically fasten.

- (7) Alternate Cap Flashing

- May be used instead of lapping membrane flashing over sleeper.

- (8) Metal Base Flashing

- Mechanically fasten to top of wood blocking, standing seam at corners, optional on flexible membrane systems. Optional on flexible membrane systems. Required on assemblies using gravel ballast filter mats.

- (9) Metal Cap Flashing

- NOTE: (8) and (9) may be one piece.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Air / Vapour Seal

- (C) Wood Blocking/Sleeper

- Minimum 150 mm (6") thick, minimum 100 mm (4") above finished roof surface.

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.