Difference between revisions of "Asphalt Shingles - Application (Low Slopes)"

Difference between revisions of "Asphalt Shingles - Application (Low Slopes)"

| Line 7: | Line 7: | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| + | ;(1) [[RoofStar Guarantee Standards for Asphalt Shingles Roof Systems#LSUNDERLAYMENT|'''Underlayment & Eave Protection''']]: One ply of self-adhered modified bituminous underlayment material. Lap 50 mm (2") minimum on sides and 150 mm (6") minimum on ends. Also refer to the [[Eave Protection & Underlayment (Asphalt Shingles, Cedar Shakes & Shingles)|'''Accepted Materials''']] section of this Manual. | ||

| + | ;(2) '''Edge Metal Flashing''': Optional (cf. [[RoofStar Guarantee Standards for Asphalt Shingles Roof Systems#LSEDGE|'''2.2.9 Wood Deck Overlay Sheathing (Non-Structural)''']] for specific requirements), installed to manufacturer's printed instructions. | ||

| + | ;(3) [[RoofStar Guarantee Standards for Asphalt Shingles Roof Systems#LSSTARTER|'''Starter Course''']]: Consists of same type shingles used for roof, applied tabs facing up the slope. | ||

| + | ;(4) '''Strip or Standard Shingles''': Applied as recommended by manufacturer. Laminated shingles are <u>not</u> acceptable for this application. | ||

| + | ;(5) '''Compatible Mastic''': Heavy bead of compatible asphaltic mastic at rakes (gables) and valleys. | ||

| + | ;(6) [[RoofStar Guarantee Standards for Asphalt Shingles Roof Systems#ASPROTRUSIONS|'''Protrusions''']]: Curbs and skylights must be flashed with underlayment so as to shed water, with minimum 125mm (5") up vertical surfaces and 150 mm (6") lapping onto field surfaces. Vent stack underlayment flashing should fit tight to the vent pipe and be sealed with compatible mastic. For fire-rated stacks or hot pipe protrusions, strip in secondary metal deck flashing before installing rated stack / pipe flashing. | ||

| + | ;(7) [[RoofStar Guarantee Standards for Asphalt Shingles Roof Systems#ASNAILING|'''Nailing''']]: Note manufacturer's recommended nailing pattern. Placement varies with manufacturer. | ||

| − | |||

| − | + | <hr> | |

| − | ( | + | === RELATED WORK BY OTHERS === |

| − | + | ;(A) [[RoofStar Guarantee Standards for Asphalt Shingles Roof Systems#ASDECK|'''Acceptable Deck''']] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | '''NOTE''': Refer to '''''RoofStar Guarantee Standards''''' for additional requirements. | ||

| − | |||

| − | |||

| − | |||

| − | |||

<hr> | <hr> | ||

Revision as of 16:13, 9 August 2016

Applicable to slopes 1:6 (2" in 12") and greater.

1 WORK INCLUDED

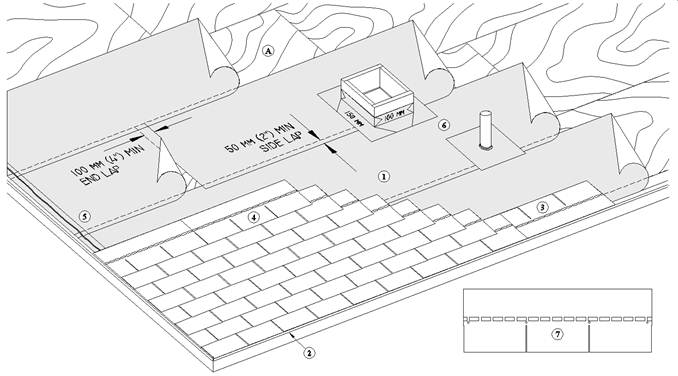

- (1) Underlayment & Eave Protection

- One ply of self-adhered modified bituminous underlayment material. Lap 50 mm (2") minimum on sides and 150 mm (6") minimum on ends. Also refer to the Accepted Materials section of this Manual.

- (2) Edge Metal Flashing

- Optional (cf. 2.2.9 Wood Deck Overlay Sheathing (Non-Structural) for specific requirements), installed to manufacturer's printed instructions.

- (3) Starter Course

- Consists of same type shingles used for roof, applied tabs facing up the slope.

- (4) Strip or Standard Shingles

- Applied as recommended by manufacturer. Laminated shingles are not acceptable for this application.

- (5) Compatible Mastic

- Heavy bead of compatible asphaltic mastic at rakes (gables) and valleys.

- (6) Protrusions

- Curbs and skylights must be flashed with underlayment so as to shed water, with minimum 125mm (5") up vertical surfaces and 150 mm (6") lapping onto field surfaces. Vent stack underlayment flashing should fit tight to the vent pipe and be sealed with compatible mastic. For fire-rated stacks or hot pipe protrusions, strip in secondary metal deck flashing before installing rated stack / pipe flashing.

- (7) Nailing

- Note manufacturer's recommended nailing pattern. Placement varies with manufacturer.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

Back to Asphalt Shingle Application