Difference between revisions of "WP Details:F1.7.7 (Walls - Low Door Sill)"

Difference between revisions of "WP Details:F1.7.7 (Walls - Low Door Sill)"

(→WORK INCLUDED) |

|||

| Line 11: | Line 11: | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | (1)<b>Primary Waterproofing Membrane:</b> Fully adhered to acceptable substrates. | + | (1) <b>Primary Waterproofing Membrane:</b> Fully adhered to acceptable substrates. |

| − | (2)<b>Membrane Flashing:</b> At walls membrane flashing must be carried up walls a minimum of 100mm (4") in height above the finished waterproofing assembly be it ballast, pavers or other permeable wearing course. At doorsill openings membrane flashing may be less than 100mm (4") in height above the finished waterproofing assembly but must not be less than 100mm (4") in height above the primary waterproofing membrane. Low doorsills shall incorporate a metal water stop flashing that is mechanically attached to the backside of doorsill framing or openings and is sealed with elastomeric or SBS membrane flashing. In addition, membrane flashing gussets must be installed at doorsill opening corners. For additional requirements refer to Section 2.1.1 Guarantee Standard A5 | + | (2) <b>Membrane Flashing:</b> At walls membrane flashing must be carried up walls a minimum of 100mm (4") in height above the finished waterproofing assembly be it ballast, pavers or other permeable wearing course. At doorsill openings membrane flashing may be less than 100mm (4") in height above the finished waterproofing assembly but must not be less than 100mm (4") in height above the primary waterproofing membrane. Low doorsills shall incorporate a metal water stop flashing that is mechanically attached to the backside of doorsill framing or openings and is sealed with elastomeric or SBS membrane flashing. In addition, membrane flashing gussets must be installed at doorsill opening corners. For additional requirements refer to Section 2.1.1 Guarantee Standard A5 |

(3) <b>Metal Base Flashing:</b> Required on all waterproofing assemblies. Flashing lengths joined by use of S-locks or standing seam joints. | (3) <b>Metal Base Flashing:</b> Required on all waterproofing assemblies. Flashing lengths joined by use of S-locks or standing seam joints. | ||

| Line 23: | Line 23: | ||

(6) <b>Metal Pan Sill Flashing:</b> Optional: Metal pan with water stop formed with pan folded, welded or soldered corners mechanically attached to inside of doorsill frame or opening and sealed with membrane flashing. | (6) <b>Metal Pan Sill Flashing:</b> Optional: Metal pan with water stop formed with pan folded, welded or soldered corners mechanically attached to inside of doorsill frame or opening and sealed with membrane flashing. | ||

(7) <b>Protection Board/Mat:</b> Proprietary membrane protection board or mat approved by membrane manufacture, compatible with waterproofing membrane system, and compliant with RGC Guarantee Standards <b>E.</b> | (7) <b>Protection Board/Mat:</b> Proprietary membrane protection board or mat approved by membrane manufacture, compatible with waterproofing membrane system, and compliant with RGC Guarantee Standards <b>E.</b> | ||

| − | |||

=== WORK BY OTHERS === | === WORK BY OTHERS === | ||

Revision as of 21:43, 19 August 2016

1 WORK INCLUDED

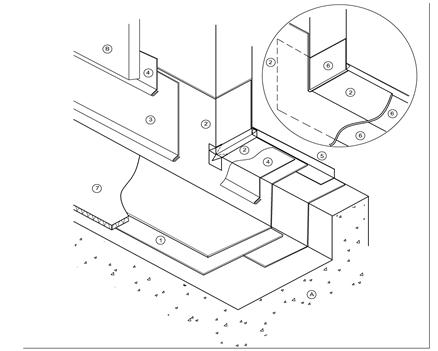

(1) Primary Waterproofing Membrane: Fully adhered to acceptable substrates.

(2) Membrane Flashing: At walls membrane flashing must be carried up walls a minimum of 100mm (4") in height above the finished waterproofing assembly be it ballast, pavers or other permeable wearing course. At doorsill openings membrane flashing may be less than 100mm (4") in height above the finished waterproofing assembly but must not be less than 100mm (4") in height above the primary waterproofing membrane. Low doorsills shall incorporate a metal water stop flashing that is mechanically attached to the backside of doorsill framing or openings and is sealed with elastomeric or SBS membrane flashing. In addition, membrane flashing gussets must be installed at doorsill opening corners. For additional requirements refer to Section 2.1.1 Guarantee Standard A5

(3) Metal Base Flashing: Required on all waterproofing assemblies. Flashing lengths joined by use of S-locks or standing seam joints.

(4) Metal Counter Flashing: Extend behind wall finish (siding) minimum 50mm (2"). Flashing lengths joined by use of S-locks or standing seam joints.

(5) Metal Water Stop Flashing: Mechanically attached to inside of doorsill framing or opening. Cut flashing to fit opening and install membrane gussets at corners.

(6) Metal Pan Sill Flashing: Optional: Metal pan with water stop formed with pan folded, welded or soldered corners mechanically attached to inside of doorsill frame or opening and sealed with membrane flashing. (7) Protection Board/Mat: Proprietary membrane protection board or mat approved by membrane manufacture, compatible with waterproofing membrane system, and compliant with RGC Guarantee Standards E.

2 WORK BY OTHERS

(A) Acceptable Deck: Concrete slab depicted.

(B) Wall Cladding and Flashing:

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

Back to Waterproofing Application