Difference between revisions of "Draft CD 3"

Difference between revisions of "Draft CD 3"

(→WORK INCLUDED) |

|||

| (21 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | { | + | |

| − | + | ||

| − | + | {{DISPLAYTITLE:<span style="position: absolute; clip: rect(1px 1px 1px 1px); clip: rect(1px, 1px, 1px, 1px);">{{FULLPAGENAME}}</span>}} | |

| − | + | __NOTOC__ | |

| − | + | ||

| + | <big><big>Division D - Construction Details</big></big> | ||

| + | <hr> | ||

| + | <big><big><big><big><big>EPDM | Membrane Termination C (Wall) ([[EPDM_Roof_Systems_Standard#10.3.2.3._General_Application_Requirements_for_Perimeters_and_Walls | Article 10.3.2.3.]])</big></big></big></big></big> | ||

| + | {{Template:Construction Details Header}} | ||

<div class="panel panel-success"> | <div class="panel panel-success"> | ||

| − | <div class="panel-heading"><big>''' | + | <div class="panel-heading"><big>'''EPDM Details'''</big></div> |

<div class="panel-body"> | <div class="panel-body"> | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

<div style="text-align:center; vertical-align:center"> | <div style="text-align:center; vertical-align:center"> | ||

| − | [[File: | + | <br> |

| − | + | [[File:10.3.2.3.-EPDM-C.png |class=img-responsive | link=https://rpm.rcabc.org/images/b/be/10.3.2.3.-EPDM-C.png]] | |

| − | + | :Drawing NTS | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

</div> | </div> | ||

| + | </div><!-- COL-6-MD --> | ||

| − | |||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | < | + | ;(1) [[EPDM Roof Systems Standard#PART_6|<big>Air/Vapour Control Layers</big>]]: |

| + | :As specified by the ''Design Authority'' and installed to provide continuity for optimal control. | ||

| + | ;(2) [[EPDM Roof Systems Standard#PART_7|<big>Insulation</big>]]: | ||

| + | :Installed in keeping with Section 7.3. Multiple layering illustrated; layers must be offset and staggered at least 304.8 mm (12”) in each direction. | ||

| + | ;(3) [[EPDM Roof Systems Standard#PART_8|<big>Insulation Overlay Panel</big>]]: | ||

| + | :Required for fully adhered membrane systems or when overburden is specified. Panels must be offset and staggered from underlying insulation panels. | ||

| + | ;(4) [[EPDM Roof Systems Standard#PART_9|<big>Field Membrane</big>]]: | ||

| + | :See Table 9.2. for permissible application methods and corresponding membrane properties. Membrane must be installed according to the requirements in Section 9.3. | ||

| + | ;(5) [[EPDM Roof Systems Standard#PART_10|<big>Edge Securement</big>]]: | ||

| + | :Proprietary to the membrane manufacturer. Edge securement is required, irrespective of how the membrane is applied (i.e., adhered, self-adhered, mechanically fastened). | ||

| + | ;(6) [[EPDM Roof Systems Standard#PART_10|<big>Mechanical Fastening</big>]]: | ||

| + | :Edge securement must be anchored to the roof structure to prevent membrane movement. | ||

| + | ;(7) [[EPDM Roof Systems Standard#PART_10|<big>Primer or Adhesive</big>]]: | ||

| + | :Proprietary to the membrane manufacturer. Primer may be required for self-adhered membranes; adhesive is required for all other applications. All membranes applied to the vertical substrate must be fully adhered. | ||

| + | ;(8) [[EPDM Roof Systems Standard#PART_10|<big>Membrane Flashing</big>]]: | ||

| + | :May be run continuously up the vertical substrate from the field or installed as separate flashing (see membrane manufacturer requirements). Membrane shall be carried up the vertical substrate at least 203.2 mm (8”) above the ''finished roof system surface'', plus at least 76.2 mm (3”) for wall control layer overlap. In regions where heavy snow accumulation is possible, or to accommodate future roof membrane replacement, membrane should be carried at least 304.8 mm (12”) up the vertical substrate. | ||

| + | ;(9) [[EPDM Roof Systems Standard#PART_10|<big>Membrane Edge Securement and Sealant</big>]]: | ||

| + | :All membranes applied to a vertical surface must be mechanically fastened. 2-component fleece-reinforced PMMA/PUMA is illustrated, together with sealant applied to upper membrane edge (See [[EPDM Roof Systems Standard#10.3.3.4. Liquid Membrane Flashing | Article 10.3.3.4.]] for application requirements); liquid membrane flashing must be compatible with the primary membrane and listed in [https://rpm.rcabc.org/index.php?title=Division_C Division C] of the RPM. | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[ | + | ;(A) [[EPDM Roof Systems Standard#PART_2|<big>Acceptable Deck</big>]] |

| − | + | :Illustrated deck is representative. See Sub-section 2.1.5. for acceptable ''deck'' types and conditions. | |

| + | ;(B) [[EPDM Roof Systems Standard#PART_2|<big>Wall Structure</big>]] | ||

| + | :Illustrated wall is representative. Wall control layers (i.e. water resistive barrier) must overlap ''roofing system'' to achieve ''continuity''. See Sub-section 2.1.7. for wall conditions. | ||

| + | |||

</div><!-- COL-6-MD --> | </div><!-- COL-6-MD --> | ||

</div><!-- PANEL BODY --> | </div><!-- PANEL BODY --> | ||

</div><!-- PANEL --> | </div><!-- PANEL --> | ||

| − | '''NOTE''': | + | '''NOTE''': See the [[EPDM Roof Systems Standard | '''EPDM Roof Systems Standard''']] for additional requirements. |

<hr> | <hr> | ||

| − | [[ | + | [[EPDM Roof System Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''EPDM Roof System Details'']] |

| + | |||

| + | [[Main Page | <i class="fa fa-home fa"></i> Home]] | ||

| − | + | {{Template:RPM Page Footer with Copyright and Current Date}} | |

Latest revision as of 15:02, 16 February 2024

Division D - Construction Details

EPDM | Membrane Termination C (Wall) ( Article 10.3.2.3.)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

EPDM Details

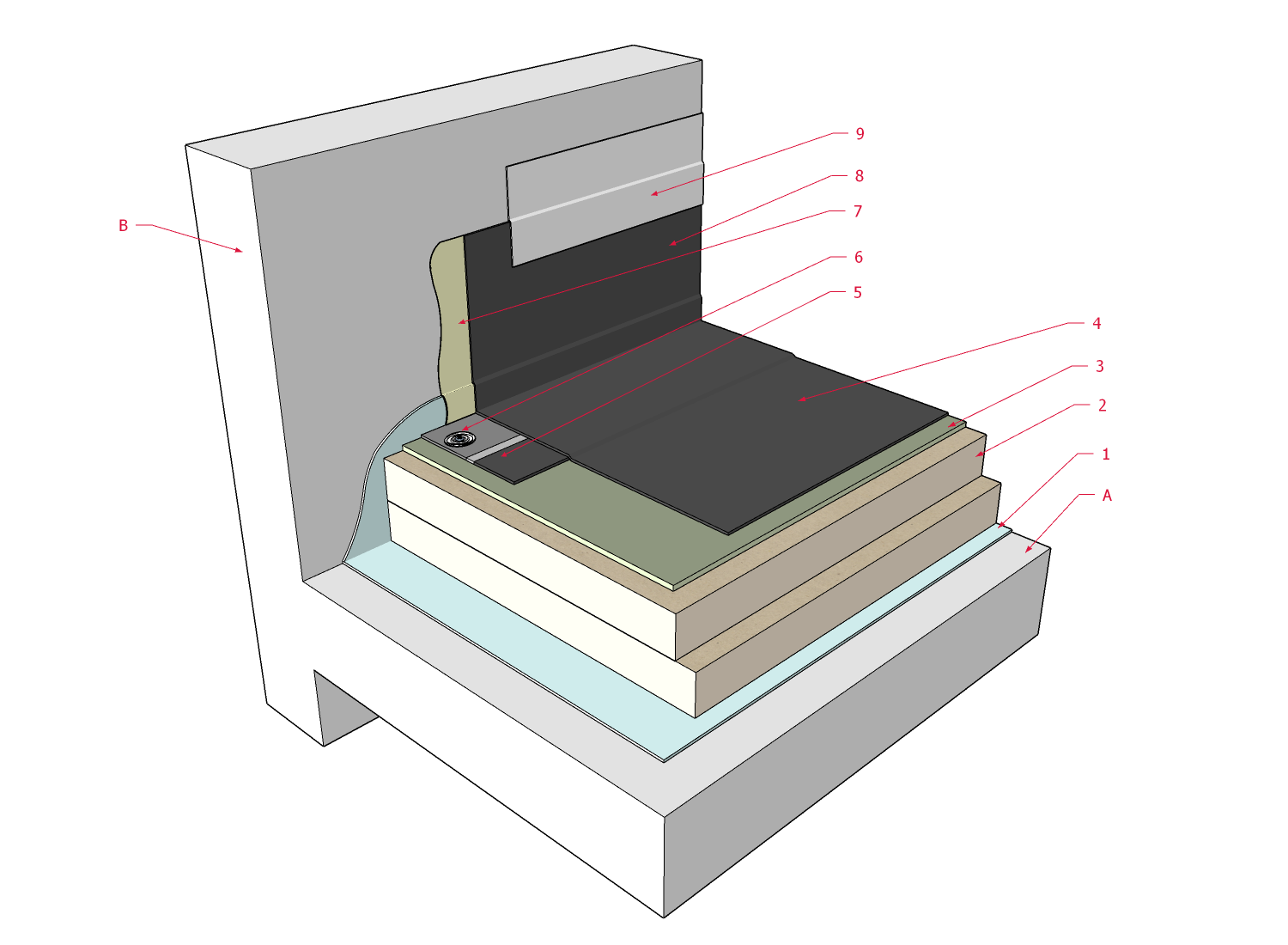

1 WORK INCLUDED

- (1) Air/Vapour Control Layers

- As specified by the Design Authority and installed to provide continuity for optimal control.

- (2) Insulation

- Installed in keeping with Section 7.3. Multiple layering illustrated; layers must be offset and staggered at least 304.8 mm (12”) in each direction.

- (3) Insulation Overlay Panel

- Required for fully adhered membrane systems or when overburden is specified. Panels must be offset and staggered from underlying insulation panels.

- (4) Field Membrane

- See Table 9.2. for permissible application methods and corresponding membrane properties. Membrane must be installed according to the requirements in Section 9.3.

- (5) Edge Securement

- Proprietary to the membrane manufacturer. Edge securement is required, irrespective of how the membrane is applied (i.e., adhered, self-adhered, mechanically fastened).

- (6) Mechanical Fastening

- Edge securement must be anchored to the roof structure to prevent membrane movement.

- (7) Primer or Adhesive

- Proprietary to the membrane manufacturer. Primer may be required for self-adhered membranes; adhesive is required for all other applications. All membranes applied to the vertical substrate must be fully adhered.

- (8) Membrane Flashing

- May be run continuously up the vertical substrate from the field or installed as separate flashing (see membrane manufacturer requirements). Membrane shall be carried up the vertical substrate at least 203.2 mm (8”) above the finished roof system surface, plus at least 76.2 mm (3”) for wall control layer overlap. In regions where heavy snow accumulation is possible, or to accommodate future roof membrane replacement, membrane should be carried at least 304.8 mm (12”) up the vertical substrate.

- (9) Membrane Edge Securement and Sealant

- All membranes applied to a vertical surface must be mechanically fastened. 2-component fleece-reinforced PMMA/PUMA is illustrated, together with sealant applied to upper membrane edge (See Article 10.3.3.4. for application requirements); liquid membrane flashing must be compatible with the primary membrane and listed in Division C of the RPM.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- Illustrated deck is representative. See Sub-section 2.1.5. for acceptable deck types and conditions.

- (B) Wall Structure

- Illustrated wall is representative. Wall control layers (i.e. water resistive barrier) must overlap roofing system to achieve continuity. See Sub-section 2.1.7. for wall conditions.

NOTE: See the EPDM Roof Systems Standard for additional requirements.

Back to EPDM Roof System Details

© RCABC 2024

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.