Difference between revisions of "TPO Conventionally Insulated System (Alternate)"

Difference between revisions of "TPO Conventionally Insulated System (Alternate)"

| (23 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | {{Template:RPM Info}} | |

| + | {{DISPLAYTITLE:<span style="position: absolute; clip: rect(1px 1px 1px 1px); clip: rect(1px, 1px, 1px, 1px);">{{FULLPAGENAME}}</span>}} | ||

| + | __NOTOC__ | ||

| + | <big><big>Division D - Construction Details</big></big> | ||

| + | <hr> | ||

| + | <big><big><big><big><big>TPO | Conventionally Insulated System (Alternate) ([[TPO_Roof_Systems_Standard#1.1.3.1._Permitted_Roof_Systems | Article 1.1.3.1.]])</big></big></big></big></big> | ||

| + | {{Template:Construction Details Header}} | ||

| + | <div class="panel panel-success"> | ||

| + | <div class="panel-heading"><big>'''TPO Details'''</big></div> | ||

| + | <div class="panel-body"> | ||

| + | <div class="col-md-6"> | ||

| + | <div style="text-align:center; vertical-align:center"> | ||

| + | [[File:6.3.2.1.jpg| link=http://rpm.rcabc.org/images/6/62/6.3.2.1.jpg | class=img-responsive]] | ||

| + | </div> | ||

| + | </div><!-- COL-MD-6 --> | ||

| + | |||

| + | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | ;(1) [[ | + | ;(1) [[TPO Roof Systems Standard#PART_6|'''Vapour Retarder''']]: If required by design authority. |

| − | ;(2) [[ | + | ;(2) [[TPO Roof Systems Standard#PART_7|'''Insulation''']]: Mechanically fastened where deck type permits, or fully adhered (as illustrated). Installed according to ''RoofStar Guarantee Standards''. See available insulation products in the [[Roof Deck Insulation|'''Accepted Materials''']] section of this Manual. |

| − | ;(3) [[ | + | ;(3) [[TPO Roof Systems Standard#PART_9|'''Adhesive''']]: Proprietary, installed according to manufacturer’s instructions, usually brushed, rolled or sprayed (3A: 2- part low rising insulation adhesive, specifically used to bond insulation and cover boards) |

| − | ;(4) [[ | + | ;(4) [[TPO Roof Systems Standard#PART_9|'''Single-ply Membrane''']]: Installed according to manufacturer’s instructions and ''RoofStar Guarantee Standards''. |

| − | ;(5) [[ | + | ;(5) [[TPO Roof Systems Standard#PART_9|'''Membrane Lap''']]: Thermoplastic membrane may be welded or chemically bonded. |

| − | ;(6) [[ | + | ;(6) [[TPO Roof Systems Standard#PART_10|'''Edge Flashing''']]: Proprietary, coated with membrane material and heat-welded to the primary (field) membrane. |

| − | ;(7) '''Fascia Flashing Clip''': Affixed to the fascia material (installed by others) with fasteners O.C. 300 mm (12”) | + | ;(7) '''Fascia Flashing Clip''': Affixed to the fascia material (installed by others) with fasteners O.C. 300 mm (12”). |

| − | ;(8) [[ | + | ;(8) [[TPO Roof Systems Standard#PART_13|'''Fascia Flashing''']]: Manufactured to RoofStar Guarantee Standards for sheet metal flashings. |

| − | ;(9) [[ | + | ;(9) [[TPO Roof Systems Standard#PART_10|'''Membrane Flashing''']]: Adhered according to manufacturer’s printed specifications using proprietary adhesive. Must be carried to the outside of the parapet or vertically to a minimum of 200 mm (8”) above the finished roof surface. Welded or adhered to primary membrane depending on membrane type. |

<hr> | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[ | + | ;(A) [[TPO Roof Systems Standard#PART_2|'''Acceptable Deck''']] |

| − | ;(B) [[ | + | ;(B) [[TPO Roof Systems Standard#PART_10|'''Acceptable Parapet Surface''']]: Surface must be smooth, dry and clean. Rough surface must be covered with treated plywood, to be determined by design authority or inspector or as required by manufacturer. |

| − | ;(C) [[ | + | ;(C) [[TPO Roof Systems Standard#PART_10|'''Edge Blocking''']] |

| − | (D) '''Fascia Material''' | + | ;(D) '''Fascia Material''' |

| − | + | </div><!-- COL-6-MD --> | |

| − | + | </div><!-- PANEL BODY --> | |

| − | + | </div><!-- PANEL --> | |

| + | '''NOTE''': See the [[TPO Roof Systems Standard | '''Standard''']] for additional requirements. | ||

<hr> | <hr> | ||

| + | [[TPO Roof System Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''TPO Construction Details'']] | ||

| + | [[Main Page | <i class="fa fa-home fa"></i> Home]] | ||

| − | + | {{Tempate:RPM Page Footer with Copyright and Current Date}} | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 21:37, 27 June 2022

Division D - Construction Details

TPO | Conventionally Insulated System (Alternate) ( Article 1.1.3.1.)

| Notice to Reader | |

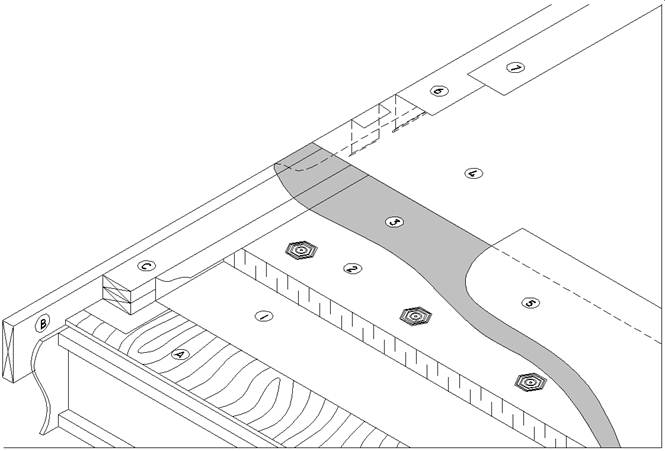

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

TPO Details

1 WORK INCLUDED

- (1) Vapour Retarder

- If required by design authority.

- (2) Insulation

- Mechanically fastened where deck type permits, or fully adhered (as illustrated). Installed according to RoofStar Guarantee Standards. See available insulation products in the Accepted Materials section of this Manual.

- (3) Adhesive

- Proprietary, installed according to manufacturer’s instructions, usually brushed, rolled or sprayed (3A: 2- part low rising insulation adhesive, specifically used to bond insulation and cover boards)

- (4) Single-ply Membrane

- Installed according to manufacturer’s instructions and RoofStar Guarantee Standards.

- (5) Membrane Lap

- Thermoplastic membrane may be welded or chemically bonded.

- (6) Edge Flashing

- Proprietary, coated with membrane material and heat-welded to the primary (field) membrane.

- (7) Fascia Flashing Clip

- Affixed to the fascia material (installed by others) with fasteners O.C. 300 mm (12”).

- (8) Fascia Flashing

- Manufactured to RoofStar Guarantee Standards for sheet metal flashings.

- (9) Membrane Flashing

- Adhered according to manufacturer’s printed specifications using proprietary adhesive. Must be carried to the outside of the parapet or vertically to a minimum of 200 mm (8”) above the finished roof surface. Welded or adhered to primary membrane depending on membrane type.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Acceptable Parapet Surface

- Surface must be smooth, dry and clean. Rough surface must be covered with treated plywood, to be determined by design authority or inspector or as required by manufacturer.

- (C) Edge Blocking

- (D) Fascia Material

NOTE: See the Standard for additional requirements.

Back to TPO Construction Details

© RCABC 2024

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.