Difference between revisions of "LMF Metal Cap Flashing (joints)"

Difference between revisions of "LMF Metal Cap Flashing (joints)"

| Line 9: | Line 9: | ||

[[File:10.2.1.jpg|class=img-responsive]] | [[File:10.2.1.jpg|class=img-responsive]] | ||

</div> | </div> | ||

| − | <div style="width: | + | <div style="width:268px; float: left;"> |

:[[File:G1.7.1 - Standing Seam Metal Clip.jpg|class=img-responsive]] | :[[File:G1.7.1 - Standing Seam Metal Clip.jpg|class=img-responsive]] | ||

</div> | </div> | ||

Revision as of 15:44, 16 November 2016

| RoofStar Guarantee Standards are blue-linked |

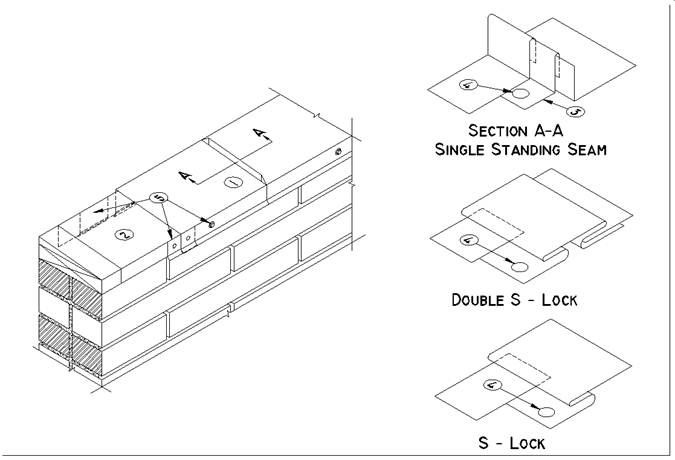

END JOINTS in metal flashings are made using any one of the joints shown in this section, providing the following rules are complied with:

(1) Expansion: Allowances should be made for expansion and contraction. Soldered joints are not acceptable.

(2) Underlayment: Membrane under cap flashing. See, for example, SBS Roof Systems, 10.3 Application.

(3) Clips: Standing seams are fastened to wood blocking before applying the following length, using screws and clips.

(4) Fasteners: S-locks and Double S-locks are screwed through the single leaf before applying the following length. See SBS Roof Systems - 12. Perimeter Flashing: Metal.

(5) Metal Cap Flashing: Fastened with continuous concealed clips or cladding screws evenly spaced between seams. See SBS Roof Systems - 12. Perimeter Flashing: Metal.

Further detail on fastening of flashing is detailed in the SMACNA Manual referenced in Section 10.2.

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.