Difference between revisions of "SBS Sealant Pocket"

Difference between revisions of "SBS Sealant Pocket"

| Line 17: | Line 17: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | ;(1) [[SBS Roof Systems Standard# | + | ;(1) [[SBS Roof Systems Standard#PART_5|'''Supporting Deck Overlay''']]: If required by design authority. |

| − | ;(2) [[SBS Roof Systems Standard# | + | ;(2) [[SBS Roof Systems Standard#PART_6|'''Air or Vapour Control Layers''']]: If required by design authority |

| − | ;(3) [[SBS Roof Systems Standard# | + | ;(3) [[SBS Roof Systems Standard#PART_7|'''Insulation''']]: Mechanically fastened. See available insulation products in the [[Roof Deck Insulation|'''Accepted Materials''']] section of this Manual. |

| − | ;(4) [[SBS Roof Systems Standard# | + | ;(4) [[SBS Roof Systems Standard#PART_8|'''Insulation Overlay''']]: As required. |

| − | ;(5) [[SBS Roof Systems Standard# | + | ;(5) [[SBS Roof Systems Standard#PART_9|'''Primary Membrane''']] and [[SBS Roof Systems Standard#SBSPROTECTION| '''Membrane Protection''']] |

;(6) '''Compatible Mastic''': Use only the membrane manufacturer's approved sealant. | ;(6) '''Compatible Mastic''': Use only the membrane manufacturer's approved sealant. | ||

| − | ;(7) [[SBS Roof Systems Standard# | + | ;(7) [[SBS Roof Systems Standard#PART_11|'''Sealant Pocket''']]: Minimum 100 mm (4") flange onto roof membrane. All corners, with the exception of one job-site formed double standing seam corner joint and adjoining lapped flange joining, shall be closed and soldered. Minimum height of gum pan to be 100 mm (4"). |

| − | ;(8) [[SBS Roof Systems Standard# | + | ;(8) [[SBS Roof Systems Standard#PART_10|'''Membrane Flashing''']]: Onto primed metal flashing flange. |

;(9) '''Packing''': To prevent displacement of compatible mastic. | ;(9) '''Packing''': To prevent displacement of compatible mastic. | ||

;(10) '''Structural Sealant''': Use only the membrane manufacturers’ approved proprietary polyurethane based structural sealant. | ;(10) '''Structural Sealant''': Use only the membrane manufacturers’ approved proprietary polyurethane based structural sealant. | ||

| Line 32: | Line 32: | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[SBS Roof Systems Standard# | + | ;(A) [[SBS Roof Systems Standard#PART_2|'''Acceptable Supporting Deck Structure''']] |

;(B) '''Protrusion''' | ;(B) '''Protrusion''' | ||

;(C) '''Wood Blocking''']] | ;(C) '''Wood Blocking''']] | ||

Revision as of 21:48, 1 September 2021

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the requirements of the Standard they represent. Unless otherwise required by the Standard, dimensions, the selection of materials and their application remains the responsibility of the Design Authority. The full text of the referenced requirements in the Standard may be read by using the blue hyperlinks | |

SBS Details

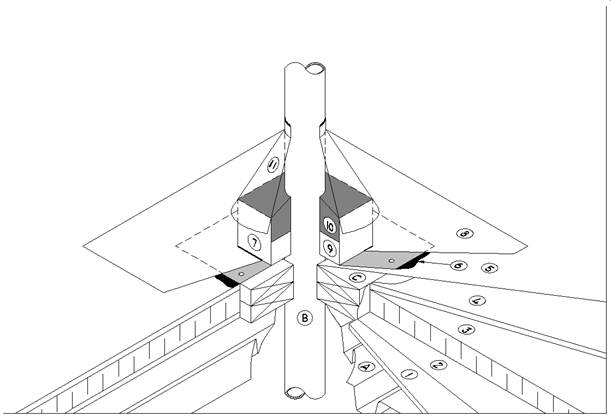

1 WORK INCLUDED

- (1) Supporting Deck Overlay

- If required by design authority.

- (2) Air or Vapour Control Layers

- If required by design authority

- (3) Insulation

- Mechanically fastened. See available insulation products in the Accepted Materials section of this Manual.

- (4) Insulation Overlay

- As required.

- (5) Primary Membrane and Membrane Protection

- (6) Compatible Mastic

- Use only the membrane manufacturer's approved sealant.

- (7) Sealant Pocket

- Minimum 100 mm (4") flange onto roof membrane. All corners, with the exception of one job-site formed double standing seam corner joint and adjoining lapped flange joining, shall be closed and soldered. Minimum height of gum pan to be 100 mm (4").

- (8) Membrane Flashing

- Onto primed metal flashing flange.

- (9) Packing

- To prevent displacement of compatible mastic.

- (10) Structural Sealant

- Use only the membrane manufacturers’ approved proprietary polyurethane based structural sealant.

- (11) Back-up Storm Collar

- To be installed whenever practical. Caulk at top of collar.

2 RELATED WORK BY OTHERS

- (A) Acceptable Supporting Deck Structure

- (B) Protrusion

- (C) Wood Blocking]]

- WARNING: DO NOT USE THIS DETAIL WITH HOT PIPES.

- AVOID THIS DETAIL: Wherever possible use Flanged Metal Stack Flashing or Curbed Opening.

NOTE: See the Standard for additional requirements.

Back to "SBS" Roof System Details

© RCABC 2026

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.