Difference between revisions of "ASM Eave and Rake Edges (Zinc)"

Difference between revisions of "ASM Eave and Rake Edges (Zinc)"

(Created page with "<hr> The details listed provide metal panel installation information and the fabrication of metal flashing details for non-ferrous metal standing seam roof systems. More speci...") |

(→RELATED WORK BY OTHERS) |

||

| Line 33: | Line 33: | ||

* Refer to <i>RGC Guarantee Standards</i> for additional requirements | * Refer to <i>RGC Guarantee Standards</i> for additional requirements | ||

* For insulated systems provide RGC accepted self-adhered modified bituminous membrane insulation underlayment. | * For insulated systems provide RGC accepted self-adhered modified bituminous membrane insulation underlayment. | ||

| + | |||

| + | |||

<hr> | <hr> | ||

| + | |||

Revision as of 18:59, 19 July 2016

The details listed provide metal panel installation information and the fabrication of metal flashing details for non-ferrous metal standing seam roof systems. More specific details are available from metal panel manufacturers.

Zinc Standing Seam metal roofing systems must meet or exceed RGC Guarantee Standards and must be installed to zinc manufacturers published roof system specifications. In addition, approved proprietary underlayment, insulation overlays and metal panel separation sheets must be installed and comply to zinc manufacturers published roof system specifications.

1 WORK INCLUDED

(1) Membrane Pre-stripping: RGC accepted self-adhered modified bituminous membrane.

(2) Ice Dam Protection / Insulation Overlay: For slopes 2:12 to 4:12 use RGC accepted self-adhered modified bituminous membrane.

(3) Panel Underlayment: Zinc manufacturer’s approved proprietary metal panel underlayment / insulation overlay protection appropriate for construction of cold or warm roof assemblies. High permeability, triple layer spun bonded non-woven polypropylene fabric underlayment and slip sheets. OR Three-dimensional high-density polyethylene or polypropylene drainage boards and mats.

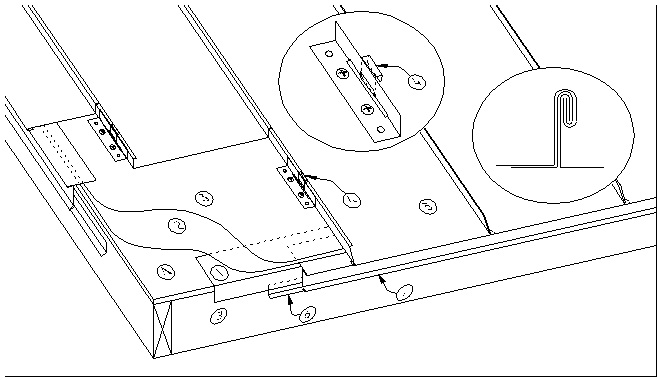

(4) Metal Panel Clip: 26 ga. (0.56 mm) thick two-piece sliding stainless steel clips at a maximum spacing of 300 mm (12") on centre. Fasten to steel deck using a minimum of two # 10-16 self-tapping steel screws with a minimum penetration of 12.5 mm (1/2"). Fasten to wood deck using a minimum of two # 8-14, 4 mm by 31 mm (1 1/4") screws.

(5) Architectural Zinc Metal Roof Panel: 0.80 mm (0.031") minimum thickness zinc conforming to European standard EN 988-1996, roll-formed to a maximum panel width of 425 mm (17") with maximum 25 mm (1") tall standing seams double-locked. Eave and rake edges to be folded around continuous edge metal flashing for panel expansion.

(6) Continuous Concealed Clip: 26 ga. (0.56 mm) thick stainless steel clip attached with screws at a maximum spacing of 200 mm (8") on centre.(7) Continuous Edge Metal Flashing: 0.80 mm (0.031") minimum thickness zinc attached with screws at a maximum spacing of 200 mm (8") on centre.

2 RELATED WORK BY OTHERS

(A) Acceptable Deck: Plywood: Minimum 15.1 mm (5/8" nominal) thick, T&G, CSA standard grade C or D. Steel: Minimum 22 ga. (0.79 mm) to ASTM A653 / A653M or A792 / A792M.

(B) Fascia Board:

NOTE:

- Refer to RGC Guarantee Standards for additional requirements

- For insulated systems provide RGC accepted self-adhered modified bituminous membrane insulation underlayment.