Difference between revisions of "TS Details:E4.7.11 (Slate - Flashings)"

Difference between revisions of "TS Details:E4.7.11 (Slate - Flashings)"

(Created page with "<hr> Flashings should be made of non-corrosive metals to match the longevity of slate. * Step Flashings (Soakers) :Step flashings are used where a long vertical detail (chimn...") |

|||

| Line 1: | Line 1: | ||

| − | < | + | <div class="panel panel-success"> |

| + | <div class="panel-heading"><big>'''Slate Roofing Details'''</big></div> | ||

| + | <div class="panel-body"> | ||

| + | <div class="col-md-6"> | ||

| + | <div style="text-align:center; vertical-align:center"> | ||

| + | [[File:7.4.1.2.10.jpg|class=img-responsive]] | ||

| + | </div> | ||

| + | </div><!-- COL-MD-6 --> | ||

| + | |||

| + | <div class="col-md-6"> | ||

| + | |||

Flashings should be made of non-corrosive metals to match the longevity of slate. | Flashings should be made of non-corrosive metals to match the longevity of slate. | ||

| Line 10: | Line 20: | ||

* Apron Flashing | * Apron Flashing | ||

:Apron Flashing is installed on the down roof side of chimneys, skylights, etc. They are used to direct water running off an object on to the down roof slates. Apron flashing should run a minimum 100 mm (4") up the vertical and extend past the exposure line of the previous course of slates. | :Apron Flashing is installed on the down roof side of chimneys, skylights, etc. They are used to direct water running off an object on to the down roof slates. Apron flashing should run a minimum 100 mm (4") up the vertical and extend past the exposure line of the previous course of slates. | ||

| − | + | </div><!-- COL-6-MD --> | |

| − | + | </div><!-- PANEL BODY --> | |

| + | </div><!-- PANEL --> | ||

<hr> | <hr> | ||

| Line 17: | Line 28: | ||

| − | [[Section:E. Application: Steep Slope Roofs|<i class="fa fa-chevron-circle-left fa | + | [[Section:E. Application: Steep Slope Roofs|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Slate Application'']] |

| − | [[Tile and Slate Construction Details|<i class="fa fa-chevron-circle-left fa | + | [[Tile and Slate Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Tile and Slate Construction Details'']] |

| − | [[Section:G. Construction Details|<i class="fa fa-chevron-circle-left fa | + | [[Section:G. Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] |

Revision as of 21:24, 19 August 2016

Slate Roofing Details

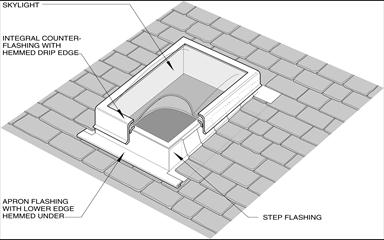

Flashings should be made of non-corrosive metals to match the longevity of slate.

- Step Flashings (Soakers)

- Step flashings are used where a long vertical detail (chimneys, walls, skylights) runs parallel to the slope. Step flashings run 100 mm (4") up the vertical and 100 mm (4") on to the slate, covering the unexposed portion, then hidden by the next course of slate. Step flashings should be 75 mm (3") longer than the slate exposure.

- Back Pans

- Back pans are used up slope from chimneys and skylights, etc. They are used to divert the water rushing against vertical to the sides then down roof. Back pans should extend at least 600 mm (24") up under the up roof slates and 100 mm (4") up the vertical. Back pans should extend at least 75 mm (3") out either side of the vertical.

- Apron Flashing

- Apron Flashing is installed on the down roof side of chimneys, skylights, etc. They are used to direct water running off an object on to the down roof slates. Apron flashing should run a minimum 100 mm (4") up the vertical and extend past the exposure line of the previous course of slates.