Difference between revisions of "Shingled Roofing Systems: Cedar Shakes & Shingles"

Difference between revisions of "Shingled Roofing Systems: Cedar Shakes & Shingles"

(→CEDAR SHAKE & SHINGLE BUREAU) |

|||

| Line 189: | Line 189: | ||

<hr> | <hr> | ||

| + | |||

| + | |||

| + | |||

| + | [[Section:C. Accepted Materials|<i class="fa fa-chevron-circle-left fa-2x" ></i> Back to ''Accepted Materials'']] | ||

| + | |||

| + | |||

| + | [[Main Page|Home]] | ||

Revision as of 18:40, 26 July 2016

1 CEDAR SHAKE & SHINGLE BUREAU

Manufacturer: CEDAR SHAKE & SHINGLE BUREAU

Contact Address: See Membership List in Section 1.

Product Group: CEDAR SHINGLES & SHAKES

Country of Origin: Canada

DESCRIPTION

The roofing assembly / material information published in this Manual DO NOT represent a complete set of the manufacturer's published data, nor does it represent a detailed specification. The preparation of a detailed specification is the responsibility of the design authority.

- Cedar shingles conforming to CSA-0118.1-97 are for slopes 1:4 (3" in 12") or greater.

- Cedar shakes conforming to CSA-0118.1-97 are for slopes 1:3 (4" in 12") or greater.

All materials used under the CERTI-LABEL Program must be manufactured by a Canadian Member Company of the Cedar Shake and Shingle Bureau. Each bundle of material must bear the “Certi-labels” and be inspected by the independent inspection agencies approved by the Bureau. Materials and their applications are detailed in Sections 7.2.1, 7.2.2, 7.2.3 and 7.2.4 of the RGC Roofing Practices Manual.

SHINGLES

Although other materials are available, the only shingles acceptable for use under the RoofStar Guarantee Program are minimum No. 1 Grade (No. 2 Grade acceptable for starter course).

Product Description

- Certigrade® Red Cedar Shingles

NO. 1 BLUE LABEL®

The premium grade of shingles for roofs and sidewalls. These top-grade shingles are 100% heartwood, 100% clear and 100% edge-grain.

- Class B & C fire rating may be obtained by specifying Certi-Guard permanent fire retardant Certigrade shingles.

- Certi-Last CCA treated shingles are available for added longevity and come with a 30-year warranty against rot and fungal decay.

SHAKES

Although other materials are available, the only shakes acceptable for use under the RoofStar Guarantee Program are Premium or No. 1 Grade of straight-split, taper-split, hand-split and resawn or tapersawn.

Product Description

Certi-Split® Red Cedar Shakes

NO. 1 HANDSPLIT & RESAWN

- These shakes have split faces and sawn backs. Cedar logs are first cut into desired lengths. Blanks or boards of proper thickness are split and then run diagonally through a bandsaw to produce two tapered shakes from each blank.

NO. 1 TAPERSPLIT

- Produced largely by hand, using a sharp-bladed steel froe and a mallet. The natural shingle-like taper is achieved by reversing the block, end-for-end, with each split.

NO. 1 STRAIGHTSPLIT

- Produced by machine or in the same manner as tapersplit shakes except that, by splitting from the same end of the block, the shakes acquire the same thickness throughout.

NO. 1 CERTI-SAWN™

- These shakes are sawn both sides.

- Class B & C fire rating may be obtained by specifying Certi-Guard permanent fire retardant Certigrade shingles.

- Certi-Last CCA treated shingles are available for added longevity and come with a 30-year warranty against rot and fungal decay.

2 QUALITY AUDITING INSTITUTE

Manufacturer: QUALITY AUDITING INSTITUTE

Contact Address: See Membership List in Section 1.

Product Group: CEDAR SHINGLES & SHAKES

Country of Origin: Canada

DESCRIPTION

The roofing assembly / material information published in the RCABC Roofing Practices Manual does NOT represent a complete set of the manufacturer's published data, nor does it represent a detailed specification. The preparation of a detailed specification is the responsibility of the design authority.

- 1.

- Cedar shingles conforming to CSA-0118.1-97 are for slopes 1:4 (3" in 12") or greater.

- Cedar shakes conforming to CSA-0118.1-97 are for slopes 1:3 (4" in 12") or greater.

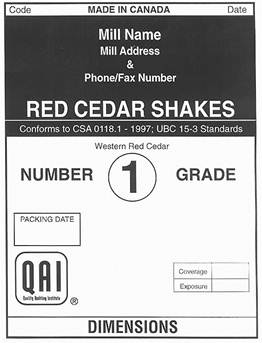

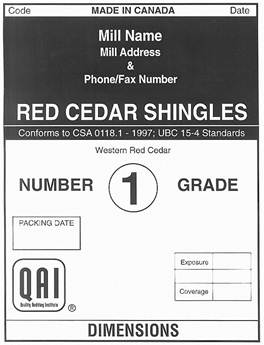

- All materials used under the RoofStar Guarantee Program must be audited by a Standards Council of Canada accredited agency. Each bundle of material must bear the ‘QAI’ label identifying the type, grade and manufacturer of the product.

- Materials and their applications are detailed in Sections 7.2.1, 7.2.2, 7.2.3 and 7.2.4 of the RCABC Roofing Practices Manual.

- Class B & C fire rating may be obtained by specifying permanent fire retardant shingles.

- CCA treated shingles are available for added longevity against rot and fungal decay

SHINGLES

Although other materials are available, the only shingles acceptable for use under the RoofStar Guarantee Program are minimum No. 1 Grade (No. 2 Grade acceptable for starter course).

Product Description

- NO. 1 BLUE LABEL ®

- The premium grade of shingles for roofs and sidewalls. These top-grade shingles are 100% heartwood, 100% clear and 100% edge-grain.

SHAKES

Although other materials are available, the only shakes acceptable for use under the RoofStar Guarantee Program are Premium or No. 1 Grade of straight-split, taper-split, hand-split and resawn or tapersawn.

Product Description

- NO. 1 HANDSPLIT & RESAWN

- These shakes have split faces and sawn backs. Cedar logs are first cut into desired lengths. Blanks or boards of proper thickness are split and then run diagonally through a bandsaw to produce two tapered shakes from each blank.

- NO. 1 TAPERSPLIT

- Produced largely by hand, using a sharp-bladed steel froe and a mallet. The natural shingle-like taper is achieved by reversing the block, end-for-end, with each split.

- NO. 1 STRAIGHTSPLIT

- Produced by machine or in the same manner as taper-split shakes except that, by splitting from the same end of the block, the shakes acquire the same thickness throughout.

- NO. 1 TAPER-SAWN

- These shakes are sawn both sides.

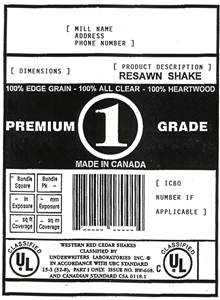

3 UNDERWRITERS LABORATORIES, INC. / UNDERWRITERS’

Manufacturer: UNDERWRITERS LABORATORIES, INC. / UNDERWRITERS’

LABORATORIES OF CANADA

Contact Address: See Membership List in Section 1.

Product Group: CEDAR SHINGLES & SHAKES

Country of Origin: U.S.A. / Canada

DESCRIPTION

The roofing assembly / material information published in the RCABC Roofing Practices Manual does NOT represent a complete set of the manufacturer's published data, nor does it represent a detailed specification. The preparation of a detailed specification is the responsibility of the design authority.

- 1.

- Cedar shingles conforming to CSA-0118.1-97 are for slopes 1:4 (3" in 12") or greater.

- Cedar shakes conforming to CSA-0118.1-97 are for slopes 1:3 (4" in 12") or greater.

- All materials used under the RoofStar Guarantee Program must be audited by a Standards Council of Canada accredited agency. Each bundle of material must bear the ‘Underwriters Laboratories, Inc.’ label identifying the type, grade and manufacturer of the product.

- Materials and their applications are detailed in Sections 7.2.1, 7.2.2, 7.2.3 and 7.2.4 of the RCABC Roofing Practices Manual.

- Class B & C fire rating may be obtained by specifying permanent fire retardant shingles.

- CCA treated shingles are available for added longevity against rot and fungal decay.

SHINGLES

Although other materials are available, the only shingles acceptable for use under the RoofStar Guarantee Program are minimum No. 1 Grade (No. 2 Grade acceptable for starter course).

Product Description

- NO. 1 BLUE LABEL ®

- The premium grade of shingles for roofs and sidewalls. These top-grade shingles are 100% heartwood, 100% clear and 100% edge-grain.

SHAKES

Although other materials are available, the only shakes acceptable for use under the RoofStar Guarantee Program are Premium or No. 1 Grade of straight-split, taper-split, hand-split and resawn or tapersawn.

Product Description

- NO. 1 HANDSPLIT & RESAWN

- These shakes have split faces and sawn backs. Cedar logs are first cut into desired lengths. Blanks or boards of proper thickness are split and then run diagonally through a bandsaw to produce two tapered shakes from each blank.

- NO. 1 TAPERSPLIT

- Produced largely by hand, using a sharp-bladed steel froe and a mallet. The natural shingle-like taper is achieved by reversing the block, end-for-end, with each split.

- NO. 1 STRAIGHTSPLIT

- Produced by machine or in the same manner as taper-split shakes except that, by splitting from the same end of the block, the shakes acquire the same thickness throughout.

- NO. 1 TAPER-SAWN

- These shakes are sawn both sides.