Difference between revisions of "TPO Conventionally Insulated System (Alternate)"

Difference between revisions of "TPO Conventionally Insulated System (Alternate)"

| Line 13: | Line 13: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | ;(1) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(1) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOVAPOUR|'''Vapour Retarder''']]: If required by design authority. |

| − | ;(2) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(2) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOINSULATION|'''Insulation''']]: Mechanically fastened where deck type permits, or fully adhered (as illustrated). Installed according to ''RoofStar Guarantee Standards''. See available insulation products in the [[Roof Deck Insulation|'''Accepted Materials''']] section of this Manual. |

| − | ;(3) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(3) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOADHESIVE|'''Adhesive''']]: Proprietary, installed according to manufacturer’s instructions, usually brushed, rolled or sprayed (3A: 2- part low rising insulation adhesive, specifically used to bond insulation and cover boards) |

| − | ;(4) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(4) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOMEMBRANE|'''Single-ply Membrane''']]: Installed according to manufacturer’s instructions and ''RoofStar Guarantee Standards''. |

| − | ;(5) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(5) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOLAP|'''Membrane Lap''']]: Thermoplastic membrane may be welded or chemically bonded. |

| − | ;(6) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(6) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOEDGE|'''Edge Flashing''']]: Proprietary, coated with membrane material and heat-welded to the primary (field) membrane. |

;(7) '''Fascia Flashing Clip''': Affixed to the fascia material (installed by others) with fasteners O.C. 300 mm (12”). | ;(7) '''Fascia Flashing Clip''': Affixed to the fascia material (installed by others) with fasteners O.C. 300 mm (12”). | ||

| − | ;(8) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(8) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOFASCIA|'''Fascia Flashing''']]: Manufactured to RoofStar Guarantee Standards for sheet metal flashings. |

| − | ;(9) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(9) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOSTRIPPING|'''Membrane Flashing''']]: Adhered according to manufacturer’s printed specifications using proprietary adhesive. Must be carried to the outside of the parapet or vertically to a minimum of 200 mm (8”) above the finished roof surface. Welded or adhered to primary membrane depending on membrane type. |

<hr> | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(A) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPODECKS|'''Acceptable Deck''']] |

| − | ;(B) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(B) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOWALLSUB|'''Acceptable Parapet Surface''']]: Surface must be smooth, dry and clean. Rough surface must be covered with treated plywood, to be determined by design authority or inspector or as required by manufacturer. |

| − | ;(C) [[RoofStar Guarantee Standards for TPO/PVC Roof | + | ;(C) [[RoofStar Guarantee Standards for TPO/PVC Roof Assemblies#TPOWOODBLOCKING|'''Edge Blocking''']] |

;(D) '''Fascia Material''' | ;(D) '''Fascia Material''' | ||

</div><!-- COL-6-MD --> | </div><!-- COL-6-MD --> | ||

Revision as of 16:55, 23 October 2017

| RoofStar Guarantee Standards are blue-linked |

TPO/PVC Details

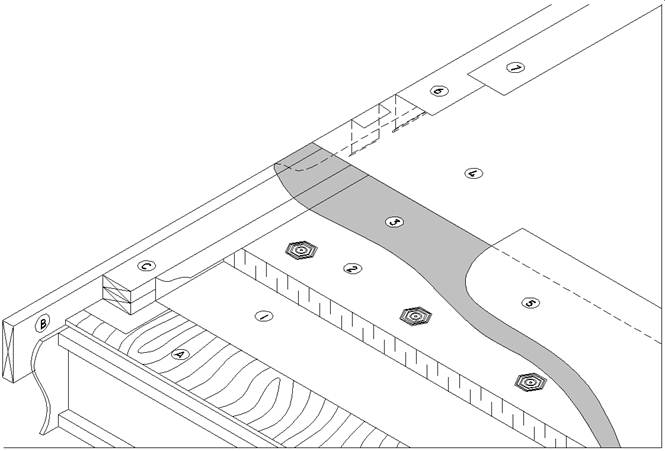

1 WORK INCLUDED

- (1) Vapour Retarder

- If required by design authority.

- (2) Insulation

- Mechanically fastened where deck type permits, or fully adhered (as illustrated). Installed according to RoofStar Guarantee Standards. See available insulation products in the Accepted Materials section of this Manual.

- (3) Adhesive

- Proprietary, installed according to manufacturer’s instructions, usually brushed, rolled or sprayed (3A: 2- part low rising insulation adhesive, specifically used to bond insulation and cover boards)

- (4) Single-ply Membrane

- Installed according to manufacturer’s instructions and RoofStar Guarantee Standards.

- (5) Membrane Lap

- Thermoplastic membrane may be welded or chemically bonded.

- (6) Edge Flashing

- Proprietary, coated with membrane material and heat-welded to the primary (field) membrane.

- (7) Fascia Flashing Clip

- Affixed to the fascia material (installed by others) with fasteners O.C. 300 mm (12”).

- (8) Fascia Flashing

- Manufactured to RoofStar Guarantee Standards for sheet metal flashings.

- (9) Membrane Flashing

- Adhered according to manufacturer’s printed specifications using proprietary adhesive. Must be carried to the outside of the parapet or vertically to a minimum of 200 mm (8”) above the finished roof surface. Welded or adhered to primary membrane depending on membrane type.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Acceptable Parapet Surface

- Surface must be smooth, dry and clean. Rough surface must be covered with treated plywood, to be determined by design authority or inspector or as required by manufacturer.

- (C) Edge Blocking

- (D) Fascia Material

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

RoofStar Guarantee Standards for TPO/PVC Roof Systems