Difference between revisions of "ASM Valley (Hooked)"

Difference between revisions of "ASM Valley (Hooked)"

| Line 12: | Line 12: | ||

<div style="width:150px; text-align: left;"> | <div style="width:150px; text-align: left;"> | ||

| − | :[[File:ASM 10.3.1 Thumb for PDF.jpg|100 px|link=http://rpm.rcabc.org/images/ | + | :[[File:ASM 10.3.1 Thumb for PDF.jpg|100 px|link=http://rpm.rcabc.org/images/6/6a/ASM_10.3.1_Hooked_Valley_Flashing.pdf|'''Print Sheet''']] |

</div> | </div> | ||

</div><!-- COL-MD-6 --> | </div><!-- COL-MD-6 --> | ||

Revision as of 17:31, 26 April 2019

| RoofStar Guarantee Standards are blue-linked |

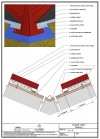

ASM Details

1 WORK INCLUDED

- (1) Architectural Metal Roof Panel

- (2) Valley Panel Overlap

- Set in two continuous rows of accepted caulking or sealant tape.

- (3) Slip Sheet

- Recommended over asphaltic underlays and / or as required by metal roof panel manufacturer.

- (4) Underlayment

- The type of underlay required is determined by roof slope.

- (5) Membrane Strip-in

- Accepted self-adhered modified bituminous eave protection membrane.

- (6) Continuous Built-In Hook Strip

- (7) Fastening

- Metal valley panels to be secured with compatible, non-corrosive, flat head fasteners 200 mm (8") o/c. Metal roof panel to metal valley panel overlap must be a minimum of 125 mm (5").

- (8) Valley Protection Membrane

- Accepted self-adhered modified bituminous eave protection membrane.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

RoofStar Guarantee Standards for ASM Roof Assemblies