Difference between revisions of "Tile Systems Standard"

Difference between revisions of "Tile Systems Standard"

| Line 1: | Line 1: | ||

| + | {{Template:RPM Info}} | ||

| + | |||

<div class="row"> | <div class="row"> | ||

Revision as of 20:38, 26 July 2021

This section contains the Standards, Guiding Principles, Recommendations and reference materials necessary for the design and installation of a roof qualifying for a RoofStar Guarantee.

All relevant Standards for the selection and application of materials necessary to qualify for a RoofStar Guarantee are found in this section. Readers are advised to review relevant materials that can be accessed through the links available in the body of text or embedded in section titles; these are shown in blue font. Subsection titles shown in blue indicate links to more relevant material that the reader is advised to consult.

Content in this section is colour-coded according to four classes:

- Guarantee Standards

- Guiding Principles

- Recommendations

- Reference materials

To hide or reveal classes of text, use the buttons at the bottom of the page. Guarantee Standards always remain visible

For definitions of these terms of reference, click here.

1 TILE

1.1 GENERAL

| NOTICE TO READER |

|---|

| This section of the RCABC Roofing Practices Manual is to provide general information on interlocking concrete roofing. The information included is intended as a general guide for specifiers. RoofStar Guarantees are NOT available for concrete roof tiles. |

Concrete tiles are available in a wide variety of styles and colours. Tiles are made of varying proportions of Portland Cement, sand and water, which is extruded in moulds under high pressure. Concrete roof tiles are manufactured to conform to CSA Standard A 220.0-M91.

1.2 MATERIALS

Concrete roof tiles are available in a wide variety of colours and styles and are frequently used to enhance the overall aesthetics of buildings.

Concrete roof tiles are made of varying proportions of Portland cement, sand and water, which is extruded on moulds under high pressure. Colour is either added to the surface or dispersed throughout the tile. Surface coloured tiles have more variety and resistance to staining by mildews, moss and pollution. Colour-through tiles keep their appearance better in heavy freeze-thaw cycling.

Standard weight concrete tiles have a minimum mass of 40 kg / m² (8 lb. / sq ft) which should be considered when calculating deck load. Manufacturers’ tile weights may vary. The minimum recommended slope for concrete tiles is 4" / 12" (1:3).

Concrete roof tiles come in two style groups with various colours and finishes:

- Roll Tile - S Shape (Spanish S)

- Flat Tile - Shake or Slate Shaped

- - Ribbed

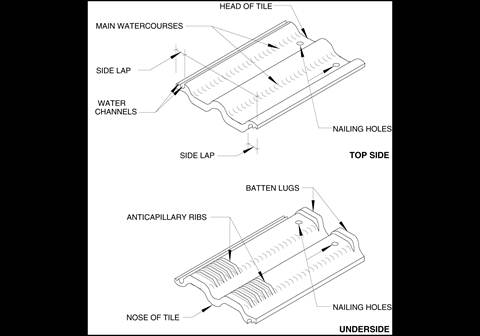

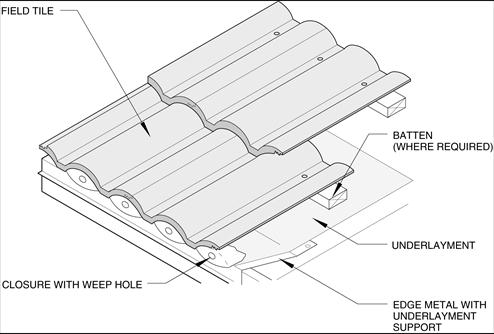

Concrete tiles are typically installed over rigid underlayment or rolled underlayment on solid sheathing. The tiles are supported by 25 mm x 100 mm (1" x 4") nominal battens, which the tiles ‘lug’ rests against, and nails through two holes which are concealed by the lap of the next course.

1.3 APPLICATION

Conform to CSA Standards A220.1-M91 (recommended).

The details listed are a general guide to the application of concrete tiles’ underlayment, battens, layout and related flashings.

1.3.1 Deck Requirements

1.3.2 Underlayment and Eave Protection

Underlayment is an integral part of concrete tile roofing systems.

- Rigid Underlayment

- Made of several plies of wood fibre material then laminated with aluminum on one side and polyethylene on the other. It comes in sheet form and may be applied directly over roof joists under the battens.

- Rolled Underlayment

- Can be #30 organic felt or a multi-layered laminated product. Felt underlayment can only be used over plywood sheathing, under the battens.

All penetrations, soil stacks, chimneys, vents, etc. should be sealed to the underlay.

Underlayments must be applied in ‘shingle’ fashion overlapping the fascia by at least 40 mm (1-1/2").

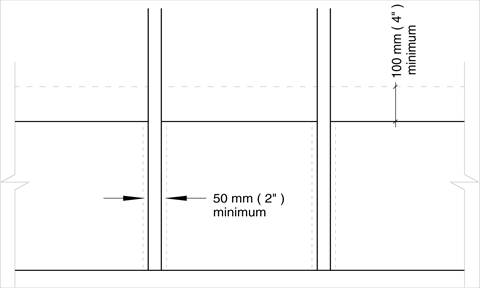

Rigid underlayment, nominally 1200 mm x 2500 mm (48" x 100"), is installed with the long side perpendicular to the slope with a minimum 50 mm (2") side lap centred on the rafters a min. 100 mm (4") overlap on previous courses.

Rolled underlayment is 900 mm - 1000 mm (36" - 39") in width and varying lengths. It is installed perpendicular to the slope with succeeding courses overlapping the previous by a minimum of 100 mm (4") and end laps a minimum of 150 mm (6").

Where a fascia board is used, the underlayment shall be fastened to the top of the fascia board at the junction of the rafter and fascia.

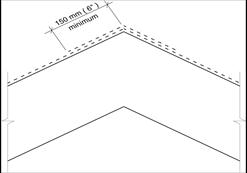

The underlayment shall lap ridges and hips 150 mm (6") in each direction, providing a total 300 mm (12") overlap.

1.3.3 Battens & Nailers

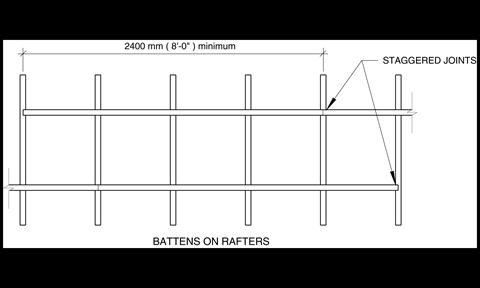

Battens are installed in conjunction with and overtop of the underlayment. The battens provide support and securement for concrete tiles.

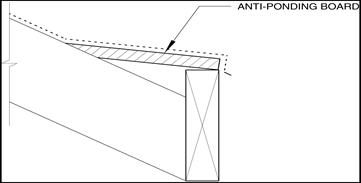

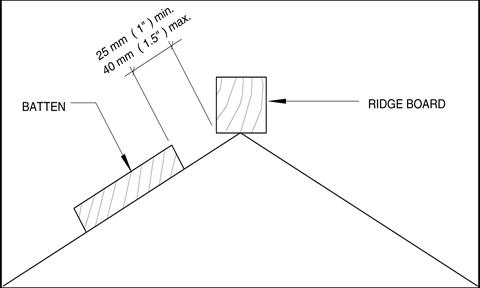

Battens are installed perpendicular to the slope, spaced to ensure a minimum 40 mm (1.5") overhang of fascia and a minimal 75 mm (3") head lap on succeeding courses. The ridge batten should be between 25 mm (1") and 40 mm (1.5") from the ridge board.

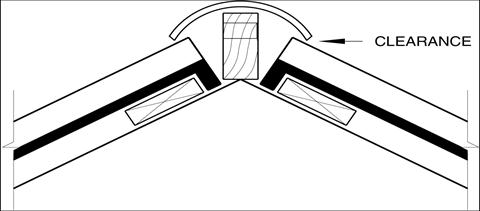

Ridge and hip boards are installed to support and provide nail securement for ridge and hip tiles. Ridge and hip boards must be installed to a height which will support the entire weight of the tile with a minimum 3 mm (1/8") clearance of the field tiles.

1.3.4 Tiles

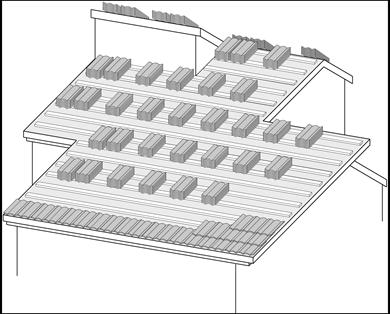

Concrete tiles are laid in shingle fashion starting at a bottom corner. To prevent excess traffic on the tiles, the roof should be loaded before any tiles are laid, usually in evenly spaced stacks of six.

Tiles are placed with the lug resting on the upperside of the batten. Nails should be a minimum 12 ga. Hot dipped galvanized, long enough to penetrate the battens but not through, to avoid penetrating the underlay. Nails should be driven just flush. Underdriven nails can crack the tile above them. Overdriving nails can crack the tile being fastened.

1.3.5 Valleys

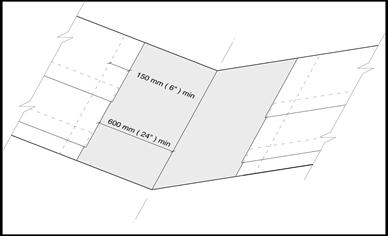

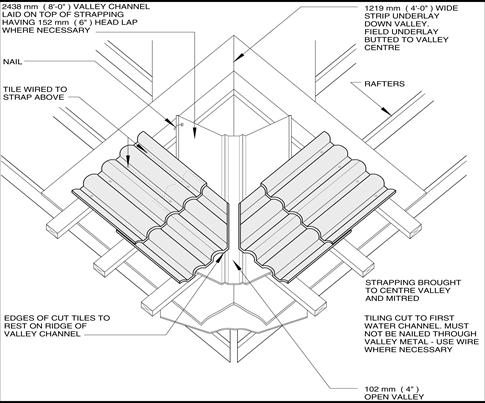

Valleys are underlayed before the field with the underlayment running centred on and parallel to the slope of the valley base. Field underlayment should overlap the valley by a minimum 150 mm (6").

Valley flashing should be 1200 mm (24") min. wide and 2400 mm (8') long with a 20 mm (1/2") divider, made of 26 ga. pre-painted steel.

The flashing should be made to conform to the valley attached with clips or nails bent over the flashing but not driven through. Under 150 mm (6") min. Laps, the previous piece should be nailed.

Valley peaks and terminations of blind valleys require lead (3 lb) transitions.

1.3.6 Hips & Ridges

Ridge and hip tiles are applied after the field tiles are terminated against the nailer board. A sealant, mortar or plaster cement should be applied to the tops of the field tile and between laps of the ridge / hip tile. This prevents entry of wind driven rain or snow.

Tiles are started at the low end of hips or the leeward end of ridges. Each tile is nailed through the hole provided into the nailer. The lap of the next tile covers the nail. The last ridge tile nails will have to be caulked.

Refer to Construction Detail E4.7.1 Tile (Hips & Ridges).

1.3.7 Rake Edges

Rake tiles cover the exposed edge of field tiles at fascia boards. This helps prevent wind driven rain from entering the system and provides an attractive finish. Rake tiles “butt” against the lower edge of the field tile courses then are fastened with two nails into the fascia.

Refer to Construction Detail E4.7.2 Tile (Rake Edge).

1.3.8 Flashings: Protrusions, Walls and Curbs

Flashings bridge the gap between field areas and any protrusions such as pipes, vents, and adjoining walls. Because these items impede the flow of water, small deficiencies can cause high amounts of water to enter the building. Proper detail work will make the difference between a successful or problematic roof.

Pipe Flashings:

Pipe flashings (E4.7.3 Tile (Pipe Flashings)) are made of lead which conforms well to the tiles’ surface. They are applied over the course of tile penetrated by the pipe and under the next course with a 75 mm (3") min. lap.

Walls Perpendicular to Slope:

Flashing for a wall termination (E4.7.4 Tile (Roof/Wall Transition)) should lap the tile by a minimum of 100 mm (4"). Material should be the 26 ga. prepainted galvanized with S locks or standing seams to join lengths.

A mortar or mastic bedding should be applied to the tops of the concrete tile before flashing to prevent wind blown rain or vermin from entering.

Curb Flashings:

Curb flashings (See E4.7.5 Tile (Curb Flashing)) are applied around skylights, chimneys or other larger penetrations. The basic principle is to deflect the water rushing against the uproof side, safely around then on top of the tiles on the down roof side.

The recommended method is to use 3 lb. lead sheeting due to its malleability and, therefore, easy conformance to the tile’s contour.

Upper and lower flashings should be conformed with tile’s surface.

Upper flashings should extend 150 mm (6") past corners on each side, then formed around soakers.

Lower flashing should extend 100 mm (4") past corners and lapped under the soakers.

For information on qualified RCABC contractors installing concrete tile roofing, please call RCABC at: (604) 882-9734 or submit an email inquiry to info@rcabc.org.

1.3.9 Nailing Requirements

Nailing frequency is determined by slope, local wind conditions and seismic zoning.

| STANDARD CONDITIONS CSA CLAUSE 11.2.2.2 | ||

| Roof Slope | Fastening for Tile | Fastening at eaves, gables, hips and ridges |

| > 1:3 < 1:1.7 | Nail or clip the tiles in every third course | Nail or clip: (a) first two courses along the eaves (b) first two courses or tiles each side of hips or ridges; and (c) first two rows in from all gables |

| > 1:1.7 < 1:1 | Nail or clip the tiles in alternate courses | |

| > 1.1 < 1.25:1 | Nail or clip every tile | Nail or clip every tile |

| > 1.25:1 | Nail or clip every tile | Nail or clip every tile |

| SEISMIC ZONE 4 OR GREATER CSA CLAUSE 11.2.2.3 | ||

| Roof Slope | Fastening for Tile | Fastening at eaves, gables, hips and ridges |

| > 1:3 < 1:1.7 | Nail or clip the tiles in every third course | Nail or clip: (a) first three courses along the eaves (b) first three courses or tiles each side of hips or ridges; and (c) first three rows in from all gables |

| > 1:1.7 < 1:1 | Nail or clip the tiles in alternate courses | |

| > 1.1 | Nail and clip every tile | Nail and clip every tile |

| HIGH WIND CONDITIONS CSA CLAUSE 11.2.2.3 | ||

| Roof Slope | Fastening for Tile | Fastening at eaves, gables, hips and ridges |

| > 1:3 < 1:1.7 | Nail and clip the tiles in every third course | Nail or clip: (a) first three courses along the eaves (b) first three courses or tiles each side of hips or ridges; and (c) first three rows in from all gables |

| > 1:1.7 < 1:1 | Nail or clip the tiles in alternate courses | |

| > 1.1 | Nail and clip every tile | Nail and clip every tile |

In areas with both high wind and seismic activity the more stringent requirements should apply.

2 SLATE

2.1 GENERAL

This section of the RCABC Roofing Practices Manual is to provide general information on slate roofing. The information included is intended as a general guide for specifiers. This material has not been submitted for consideration under the RoofStar Guarantee Program.

Slate is a naturally occurring stone material which is formed of compressed sedimentary particles of clay and silt built up on ancient sea beds. The layering of the materials gives slate a natural cleavage which allow it to be split into thin layers. Slate also has a natural grain at right angles to the cleave. Slate colours vary from region to region due to slight mineral composition differences. Colours include black, green, grey, purple and red, or ribboned with various combinations of these colours. Combinations of colour can be used to enhance the aesthetic appeal.

2.2 MATERIALS

Roofing slate is tested in accordance with ASTM test method to determine the following:

ASTM-C-406-89

- Modulus of rupture (breakage) 9,000 lb / square inch minimum

- Weathering resistance (water absorption) to resist freeze thaw damage and delamination. Maximum absorption - .002%

- Depth of softening (scratch test)

- Classifications

- S-1 rated for 75 to 100 year service

- S-2 rated for 40 to 60 year service

- S-3 rated for 10 to 25 year service

- Thickness

- Slate is cleaved by hand and sight-measured for nominal thickness. Thickness variances are considered natural. Minimum nominal thickness for roofing slate is 4 mm (3/16").

2.3 APPLICATION

2.3.1 Deck Requirements

Slate roofing needs a minimum slope of 1:3 (4" in 12") to achieve required runoff. Slate can be installed over 16 mm (5/8") plywood or 24 mm x 100 mm (1" x 4") strapping.

2.3.2 Underlayment and Eave Protection

Slate should have ice dam protection at the eaves and an underlayment of #30 asphalt saturated felt laid perpendicular to the slope with end laps min. 100 mm (4") and 100 mm (4") laps on successive courses. Valleys should be run vertically with field rolls overlapping at least 300 mm (12"). Hips and ridges should be overlapped 300 mm (12") in both directions.

2.3.3 Slate

Slate is available in three nominal thicknesses:

Standards 4 mm - 6 mm (3/16" - 1/4")

Quarters 6 mm - 8 mm (1/4" - 3/8")

Heavies 8 mm - 12 mm (3/8" - 1/2")

The different thicknesses of slates should not be mixed. Using slates of different thickness in a course will result in an uneven substrate for slates of the succeeding course, which may result in breakage. Slates for a given roof area should be mixed before application to ensure an even colour blend.

The roof deck should be loaded with slates required for that area before application begins to prevent excessive traffic from damaging slates already laid. Starter courses must be doubled or be underlaid with specially cut starter slates.

Slate is installed in a 2 ply shingle fashion with a minimum head lap of 75 mm (3") for roofs with a 1:2 (6"/12") and greater slope or 100 mm (4") for roofs with slopes between 1:3 (4"/12") and 1:2 (6"/12"). Slates should be staggered on successive rows with more than 75 mm (3") difference. Slate can be either uniform width or random width. Most slate comes with two pre-punched holes for nailing and should be applied with copper nails, considering the expected life of a slate roof can be up to 100 years. Nails should be driven just flush so as not to crack the slate over or under.

Additional holes can be made by use of a zax. The holes should be struck on the underside so the spalling will create a countersink for the nail head.

2.3.4 Valleys

Valleys on a slate roof can be done in several ways including swept, laced, mitred and open. The recommended style for B.C. is open valleys, due to ease of installation and better drainage of debris. It is recommended that copper, lead or stainless steel be used to match the longevity of slate.

Valley metal should be a minimum of 600 mm (24") wide and be centre crimped. Successive pieces should lap a minimum 150 mm (6"). Valley metal sections should be drag load fastened and sealed between laps with a compatible caulking. Slates should extend a minimum of 150 mm (6") into the valley with the cut line being tapered 1% from bottom to top.

2.3.5 Hips & Ridges

Hips

Hips on a slate roof can be either mitred, saddled or have a metal flashing.

Saddled hips require a lathe nailer on both sides thick enough to support the hip tiles from the field tiles. The width should allow nailing and keep a 75 mm (3") lap over field tiles. Nail heads should be covered with elastic cement between successive tiles.

On mitred hips, field slates are cut flush at the apex to match slates on the other side. The unexposed portion of these slates is covered with a metal flashing which should extend 50 mm up from the tiles being covered.

Ridges

Ridges have several traditional styles including saddled or a metal flashing. Ridges are installed after the field slates are installed flush with each other on opposite sides of the ridge.

- Saddle Ridges

- The slates are run horizontally and overlapping with the nails being driven between slates of the last course. Elastic cement should be applied in overlaps and joints on top of the ridge.

- Metal Ridge Cap

- Metal used for a ridge cap should be non-corrosive to last the life of a slate roof. It is installed on a ridge board and must cover the last course of slate down to its normal exposure. Attachment is provided by hidden clips.

2.3.6 Rake Edges

Under construction

2.3.7 Flashings: Protrusions, Walls and Curbs

Flashings should be made of non-corrosive metals to match the longevity of slate.

- Step Flashings (Soakers)

- Step flashings are used where a long vertical detail (chimneys, walls, skylights) runs parallel to the slope. Step flashings run 100 mm (4") up the vertical and 100 mm (4") on to the slate, covering the unexposed portion, then hidden by the next course of slate. Step flashings should be 75 mm (3") longer than the slate exposure.

- Back Pans

- Back pans are used up slope from chimneys and skylights, etc. They are used to divert the water rushing against vertical to the sides then down roof. Back pans should extend at least 600 mm (24") up under the up roof slates and 100 mm (4") up the vertical. Back pans should extend at least 75 mm (3") out either side of the vertical.

- Apron Flashing

- Apron Flashing is installed on the down roof side of chimneys, skylights, etc. They are used to direct water running off an object on to the down roof slates. Apron flashing should run a minimum 100 mm (4") up the vertical and extend past the exposure line of the previous course of slates.

- Pipe Flashings

- Lead pipe flashings work well with slate. Pipe flashings are laid over preceding courses and under successive courses of slate.

For information on qualified RCABC contractors installing slate roofing, please call RCABC at: (604) 882-9734 or email info@rcabc.org.

2.3.8 Nailing Requirements

- Slate nails should be copper or stainless steel, although copper is recommended. Standard thickness slate may be applied with 38 mm (1 ½") nails, with 50 mm (2") for hips and ridges. Thicker slate requires longer and heavier gauge nails. Add 25 mm (1") to twice the thickness. Nail holes are machine punched or drilled.

- Minimum shank diameter should be 3 mm (1/8") or No. 11 Stubs gauge but thick slate requires longer length and larger diameter. Slope, weight of slate, wind loads and roof sheathing should also be considered when determining shank gauge.

Slate Size

- To relieve uniformity of shadow line, architects have continued to specify one length and random widths.

| Length | Standard Widths | Exposure with Standard 75 mm (3") Headlap |

| 600 mm (24") | 400 - 350 - 300 mm | 263 mm |

| (16" - 14" - 12") | (10 ½") | |

| 550 mm (22") | 350 - 300 - 275 mm | 238 mm |

| (14" - 12" - 11") | (9 ½") | |

| 500 mm (20") | 350 - 300 - 275 - 250 mm | 213 mm |

| (14" - 12" - 11" - 10") | (8 ½") | |

| 450 mm (18") | 350 - 300 - 275 - 250 - 225 mm | 188 mm |

| (14" - 12" - 11" - 10" - 9") | (7 ½") | |

| 400 mm (16") | 350 - 300 - 275 - 250 - 225 - 200 mm | 163 mm |

| (14" - 12" - 11" - 10" - 9" - 8") | (6 ½") | |

| 350 mm (14") | 300 - 275 - 250 - 225 - 200 - 175 mm | 138 mm |

| (12" - 11" - 10" - 9" - 8" - 7") | (5 ½") | |

| 300 mm (12") | 300 -250 - 225 - 200 - 175 - 150 mm | 113 mm |

| (12" - 10" - 9" - 8" - 7" - 6") | (4 ½") | |

| 250 mm (10") | 250 - 225 - 200 - 175 - 150 mm | 88 mm |

| (10" - 9" - 8" - 7" - 6") | (3 ½") |

| Weight | ||

| Standard Smooth Texture | 318 - 386 kg / Sq | (700 to 850 lb / Sq) |

| 6 - 10 mm (1/4" - 3/8") Rough Texture | 454 kg / Sq | (1000 lb / Sq) |

| 10 - 13 mm (3/8" - 1/2") Rough Texture | 680 kg / Sq | (1500 lb / Sq) |

| 13 - 19 mm (1/2" - 3/4") Rough Texture | 1040 kg / Sq | (2300 lb / Sq) |

| 19 - 25 mm (3/4" - 1") Rough Texture | 1450 kg / Sq | (3200 lb / Sq) |