Difference between revisions of "SBS Expansion Joint (Field)"

Difference between revisions of "SBS Expansion Joint (Field)"

(→RELATED WORK BY OTHERS) |

|||

| Line 2: | Line 2: | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | (1) | + | ;(1) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSVAPOUR|'''Vapour Retarder''']]: If required by design authority |

| − | + | ;(2) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSINSULATION|'''Insulation''']]: See available insulation products in the [[Roof Deck Insulation|'''Accepted Materials''']] section of this Manual. | |

| − | (2) | + | ;(3) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSINSULATIONOVERLAY|'''Insulation Overlay''']]: As required. |

| − | + | ;(4) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSBASE|'''Primary Membrane and Membrane Protection''']] | |

| − | (3) | + | ;(5) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSSTRIPTERM|'''Membrane Flashing''']]: Mechanically fasten to top of blocking (C). |

| − | + | ;(6) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSSTRIPTERM|'''Flashing Underlay''']]: Minimum self-adhered modified bitumen or as per membrane manufacturer’s recommended detail. | |

| − | (4) | + | ;(7) [[RoofStar Guarantee Standards for SBS Roof Systems#METALCAP-SBS|'''Metal Base Flashing''']]: Mechanically fasten to top of wood blocking. Optional on flexible membrane systems. Required on assemblies using gravel ballast filter mats. |

| − | + | ;(8) [[RoofStar Guarantee Standards for SBS Roof Systems#METALCAP-SBS|'''Metal Cap Flashing''']]: Top surface must be sloping. Extend beyond and over-break at top corners. Fasten with concealed clip-type fasteners <b>or</b> cladding screws evenly spaced between seams. | |

| − | (5) | ||

| − | |||

| − | (6) | ||

| − | |||

| − | (7) | ||

| − | |||

| − | (8) | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | (A) | + | ;(A) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSDECKS|'''Acceptable Deck''']] |

| − | + | ;(B) '''Air / Vapour Seal''' | |

| − | (B) | + | ;(C) [[RoofStar Guarantee Standards for SBS Roof Systems#SBSEXPANSION|'''Expansion Joint Assembly''']]: Minimum 200 mm (8") and maximum 300 mm (12") above finished roof surface. Minimum height may be reduced to 100mm (4") if the primary roof membrane flashing is fully supported and sealed over the top. Primed where applicable. Top must be sloped. |

| − | + | ;(D) <b>Flexible Insulation</b> | |

| − | (C) | ||

| − | |||

| − | (D) <b>Flexible Insulation</b> | ||

Revision as of 17:56, 4 August 2016

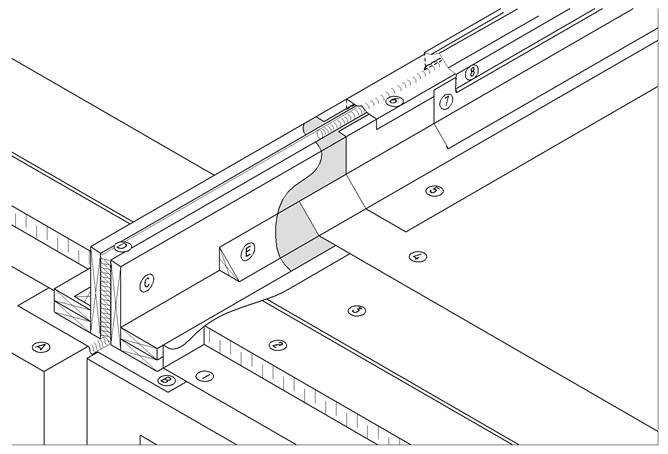

1 WORK INCLUDED

- (1) Vapour Retarder

- If required by design authority

- (2) Insulation

- See available insulation products in the Accepted Materials section of this Manual.

- (3) Insulation Overlay

- As required.

- (4) Primary Membrane and Membrane Protection

- (5) Membrane Flashing

- Mechanically fasten to top of blocking (C).

- (6) Flashing Underlay

- Minimum self-adhered modified bitumen or as per membrane manufacturer’s recommended detail.

- (7) Metal Base Flashing

- Mechanically fasten to top of wood blocking. Optional on flexible membrane systems. Required on assemblies using gravel ballast filter mats.

- (8) Metal Cap Flashing

- Top surface must be sloping. Extend beyond and over-break at top corners. Fasten with concealed clip-type fasteners or cladding screws evenly spaced between seams.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Air / Vapour Seal

- (C) Expansion Joint Assembly

- Minimum 200 mm (8") and maximum 300 mm (12") above finished roof surface. Minimum height may be reduced to 100mm (4") if the primary roof membrane flashing is fully supported and sealed over the top. Primed where applicable. Top must be sloped.

- (D) Flexible Insulation

NOTE: Refer to RGC Guarantee Standards for additional requirements.