Difference between revisions of "ASM Cylindrical Penetration (Flexible Boot Flashing)"

Difference between revisions of "ASM Cylindrical Penetration (Flexible Boot Flashing)"

(→WORK INCLUDED) |

|||

| Line 11: | Line 11: | ||

;(7) '''Seal Between Pipe And Flashing''': Continuous tooled bead of accepted caulking. | ;(7) '''Seal Between Pipe And Flashing''': Continuous tooled bead of accepted caulking. | ||

;(8) '''Stainless Steel Drawband''' | ;(8) '''Stainless Steel Drawband''' | ||

| − | ;(9) '''Water Tight Back Up Storm Collar''': Installed where practical. | + | ;(9) '''Water Tight Back Up Storm Collar''': Installed where practical. |

| + | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

Revision as of 17:14, 10 August 2016

1 WORK INCLUDED

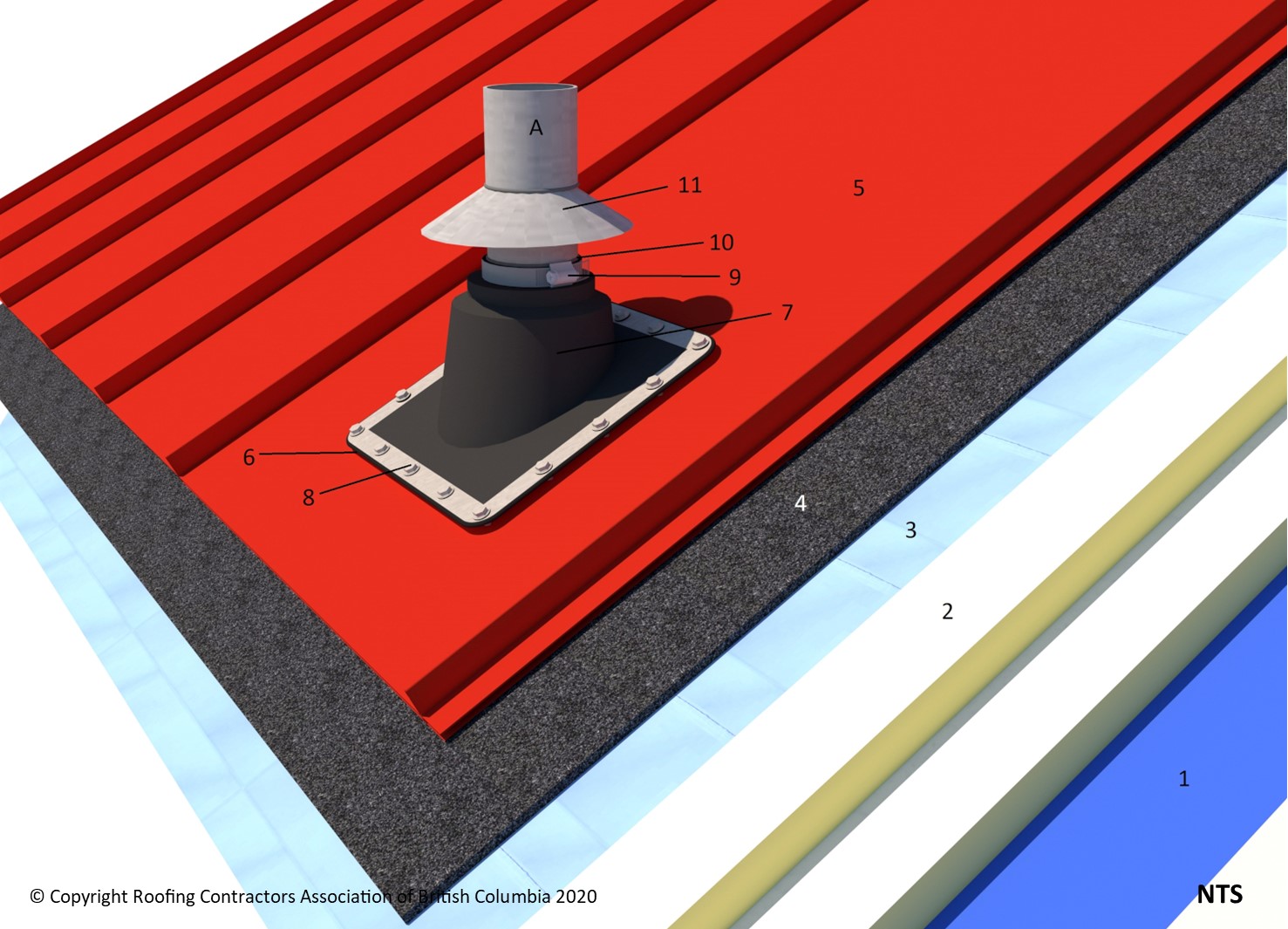

- (1) Underlayment

- The type of underlay required is determined by roof slope.

- (2) Slip Sheet

- Recommended over asphaltic underlays and / or as required by metal roof panel manufacturer.

- (3) Valley Metal Panel

- (4) Flange

- Set in two continuous beads of accepted caulking.

- (5) Preformed Penetration Collar

- (6) High-domed Gasketed Cladding-type Screws

- Flange fastened to manufacturer.s specifications.

- (7) Seal Between Pipe And Flashing

- Continuous tooled bead of accepted caulking.

- (8) Stainless Steel Drawband

- (9) Water Tight Back Up Storm Collar

- Installed where practical.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Location Of Penetrations

- Must not interfere with standing seams or trapezoidal and intermediate ribs.

- (C) Opening In Roof Deck

- Must be large enough to allow for thermal movement of metal roof panels.

- (D) Pipe Or Support Stand

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.