Draft CD 3

Draft CD 3

| Notice to Reader | |

| Images used in a Construction Detail are representative and not intended in their representation of an assembly to be prescriptive. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the Standards, Guiding Principles and Recommendations of the RoofStar Guarantee Standards for a Waterproofing or Water-shedding System. Actual design with respect to dimensions, the selection of materials and their application remains the responsibility of the Design Authority. The full text of applicable RoofStar Guarantee Standards may be read by using the blue hyperlinks | |

SBS Details

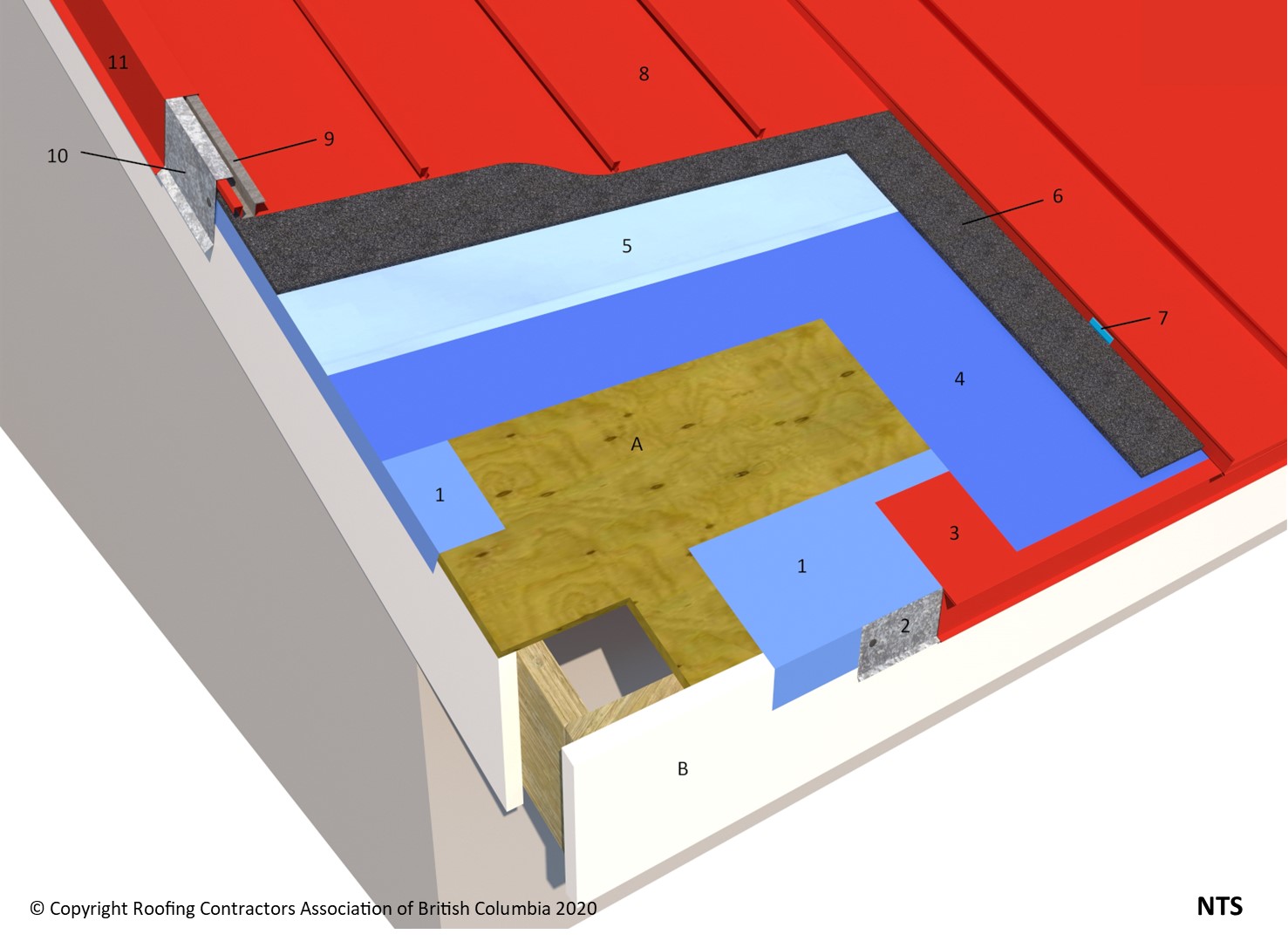

1 WORK INCLUDED

- (1) Separation membrane, applied above deck and beneath metal eave flashing

- (2) Hook securement strip.

- (3) Eave metal flashing.

- (4) Eave Protection

- One ply of self-adhered modified bituminous underlayment material. Lap 50 mm (2") minimum on sides and 100 mm (4") minimum on ends.

- (5) Underlayment

- Applicable to roof slopes 1:3 or greater. For slopes less than 1:3, the entire roof slope must be covered with a self-adhered underlayment.

Architectural Metal Roof Panel

- (2) Ventilation Layer

- Recommended over asphaltic underlays and / or as required by metal roof panel manufacturer.

- (3) Underlayment

- The type of underlay required is determined by roof slope.

- (4) Metal Panel Clip

- Installed to metal roof panel manufacturer’s printed instructions.

- (4) Architectural Metal Roof Panel

- (5) Eave Protection

- One ply of self-adhered modified bituminous underlayment material. Lap 50 mm (2") minimum on sides and 100 mm (4") minimum on ends.

- (6) Metal flashing underlayment/separation membrane

- required for metal flashings installed on wood substrates.

- (7) Edge Metal Flashing (Continuous)

- (8) Continuous metal cleat

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Fascia Board

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems