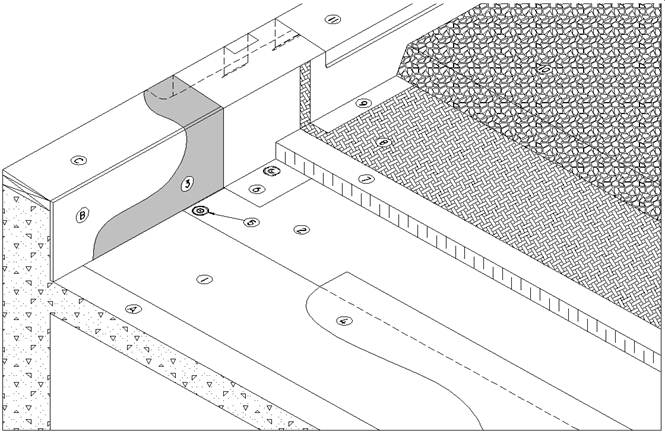

EPDM Protected Roof Assembly (Typical)

EPDM Protected Roof Assembly (Typical)

1 WORK INCLUDED

(1) Protection Mat: Provide protection between concrete deck and membrane with installation of manufacturer specified and RGC accepted protection mat or deck overlay boards.

(2) Single Ply Membrane: Installed according to manufacturer’s instructions and RGC Guarantee Standards Section 2.1.1 and Section 2.1.3.

(3) Adhesive: Proprietary, installed according to manufacturer’s instructions, usually brushed, rolled or sprayed.

(4) Membrane Lap: Thermoplastic membrane may be welded or chemically bonded (See Section 6.2) Thermoset membrane may be joined using uncured tape or proprietary adhesive (See Section 6.1).

(5) Fasteners: Install according to manufacturer’s instructions (may vary from drawing).

(6) Membrane Flashing: Adhered according to manufacturer’s printed specifications using proprietary adhesive. Must be carried to outside of parapet or minimum 200 mm (8") above finished roof surface. Welded or adhered to primary membrane depending on membrane type.

(7) Insulation: Installed according to RGC Guarantee Standard A4.3. See Section 2.2 for accepted materials.

(8) Filter Fabric: Metal base flashing required. (See RGC Guarantee Standard A6.9.1.2)

(9) Metal Flashing: As required by RGC standards. (See RGC Guarantee Standards A6.9 and A6.10.)

(10) Ballast: Gravel or concrete paving tiles.

(11) Parapet Flashing: As required by RGC standards. (See RGC Guarantee Standards A6.9 and A6.10.)

2 RELATED WORK BY OTHERS

(A) Acceptable Deck

(B) Acceptable Parapet Surface: Surface must be smooth, dry and clean. Rough surface must be covered with treated plywood, to be determined by design authority or inspector or as required by manufacturer. (See RGC Guarantee Standard A1.5.1)

(C) Sloped Wood Blocking: As per RGC Guarantee Standard A6.9.1

NOTE: • Refer to RGC Guarantee Standards for additional requirements