SBS Mechanical Equipment Curb

SBS Mechanical Equipment Curb

Revision as of 18:19, 27 October 2023 by James Klassen (talk | contribs)

Division D - Construction Details

SBS | Mechanical Equipment Curb ( Article 12.3.2.4.)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

SBS Details

1 WORK INCLUDED

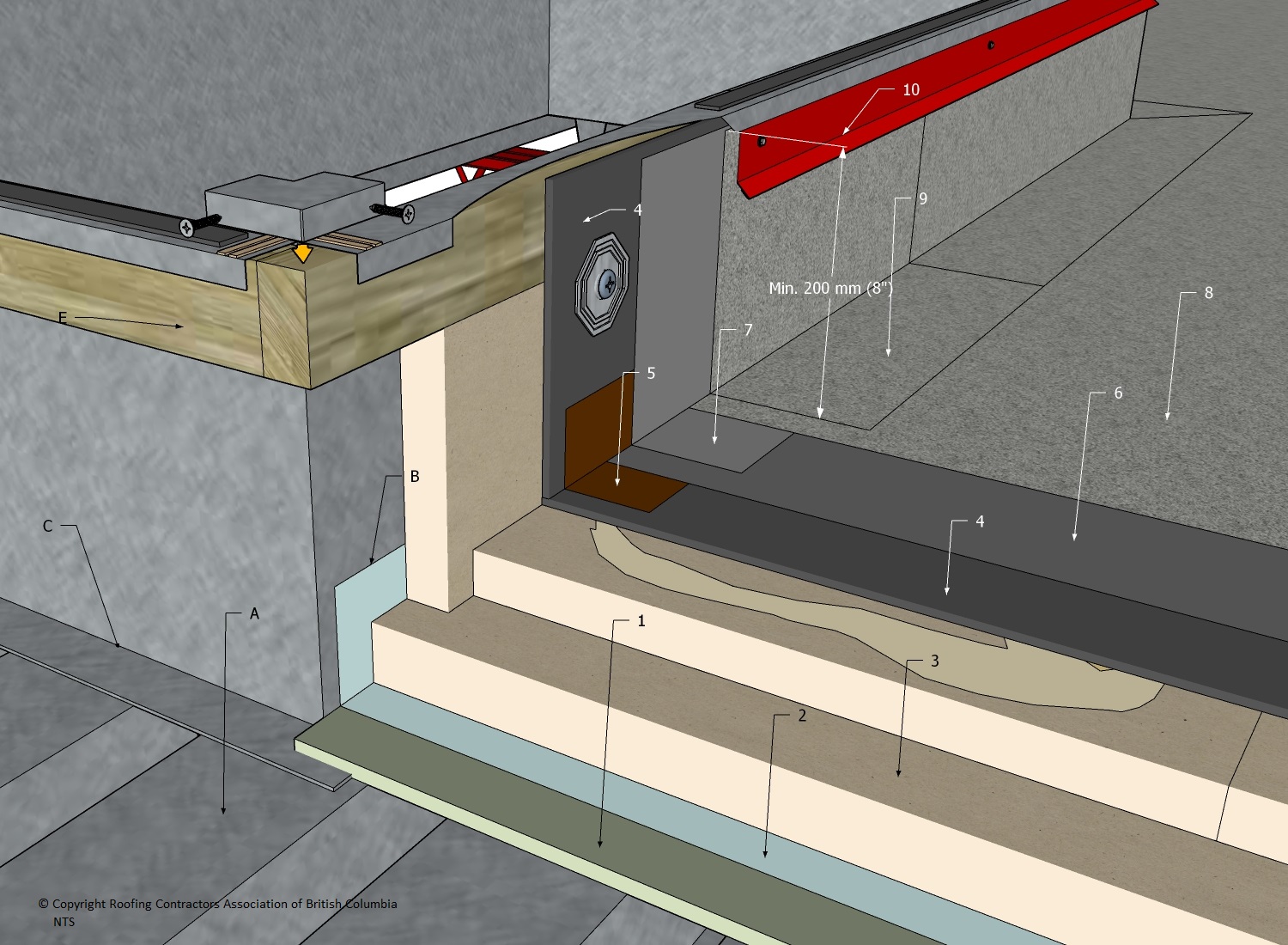

- (1) Supporting Deck Overlay

- Required when insulation is too thin to span flutes of steel decking or when required as thermal barrier by design authority.

- (2) Air or Vapour Control Layers

- If required by design authority.

- (3) Insulation

- Mechanically fastened. See available insulation products in the Accepted Materials Division of this Manual.

- (4) Insulation Overlay

- As required.

- (5) Flame protection (membrane strip)

- Also refer to the Standard for alternative methods for handling flame-sensitive details and roof perimeters.

- (6) Base Field Membrane

- Adhered to overlay board using asphalt, cold adhesive, self-adhered, mechanical attachment or torch applied according to manufacturer's specification. Torching directly to wood surfaces is not permitted.

- (7) Base Membrane Flashing

- Adhered according to manufacturer's specifications, using cold adhesive, hot asphalt, self-adhered or torch applied to cover boards, or mechanically attached membrane. Must be tucked under metal flange and mechanically attached to nailing strip.

- (8) Cap Field Membrane

- Applied according to manufacturer's printed instructions and to RoofStar Guarantee Standards.

- (9) Cap Membrane Flashing

- Applied according to manufacturer's printed instructions and to RoofStar Guarantee Standards. Must be tucked under metal flange and mechanically attached to the nailing strip.

- (10) Metal Flashing

- Mechanically fasten, standing seam at corners. Full width base flashing optional on flexible membranes. Partial skirt flashing minimum 75 mm (3") required on mechanical curbs that require flashing under metal flange.

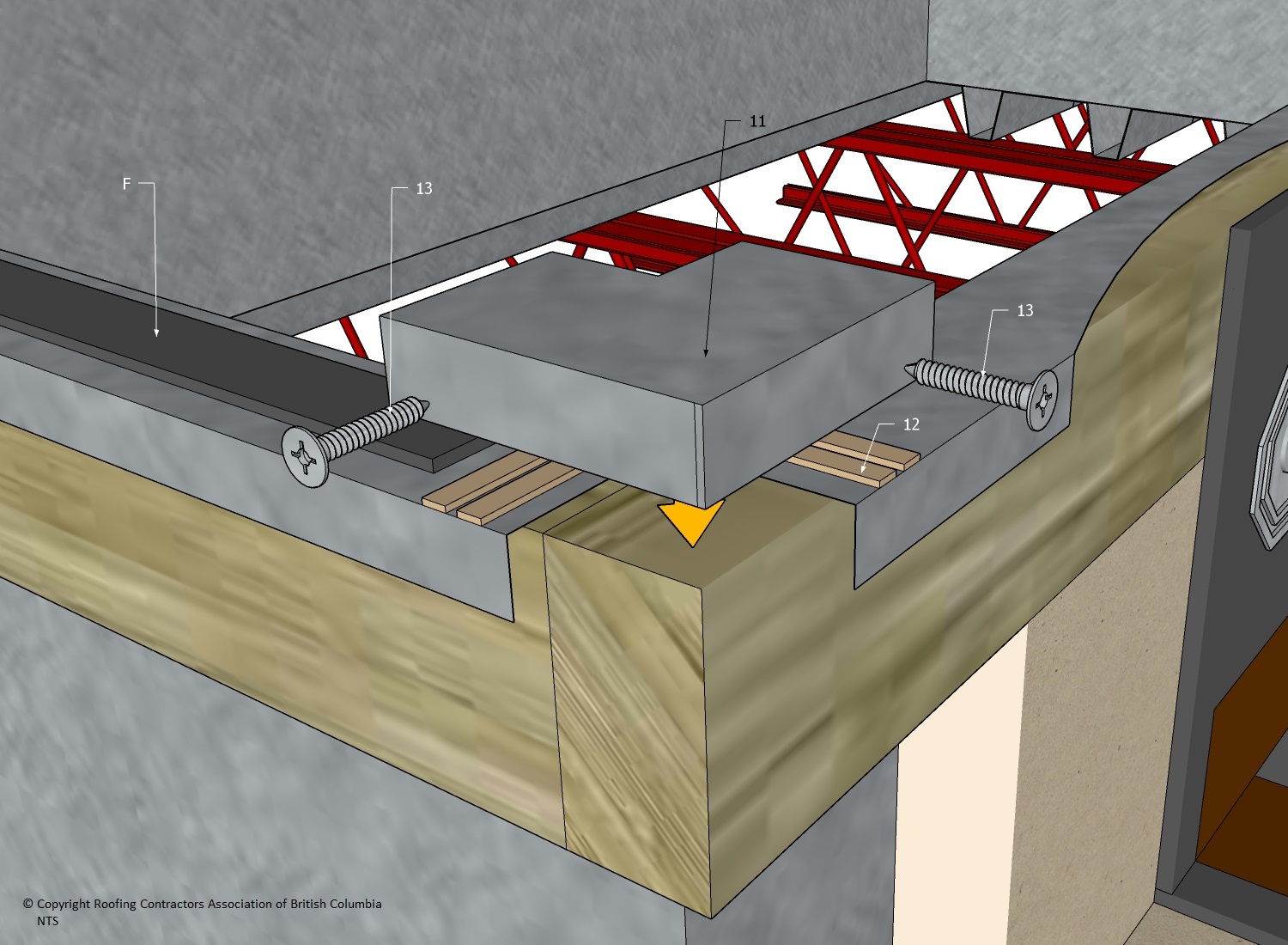

- (11) Alternate Corner Cap (Shop-manufactured)

- Weld seams. Bed in two parallel courses of butyl tape or acceptable sealant. Mechanically fasten to outside face of curb flange.

- (12) Butyl Tape (sealant)

- (13) Fasteners

- Flanged fasteners with neoprene washers.

2 RELATED WORK BY OTHERS

- (A) Supporting Deck Structure

- (B) Air or Vapour Control Layer Seal

- Air and vapour controls installed by others should be made accessible to the Contractor for connection, to maintain continuity across assemblies and throughout the building enclosure.

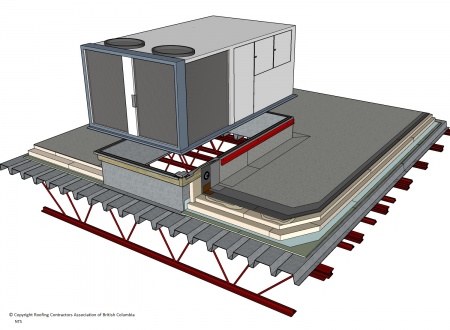

- (C) Mechanical Curb

- Minimum 200 mm (8") above finished roof surface.

- Some mechanical curbs are designed to allow membrane flashing to be carried up onto metal flange. Install according to manufacturers’ instructions.

- (D) Wood Nailing Board

- (E) Neoprene Gasket for RTU

NOTE: See the Standard for additional requirements.

Back to "SBS" Roof System Details

© RCABC 2026

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.