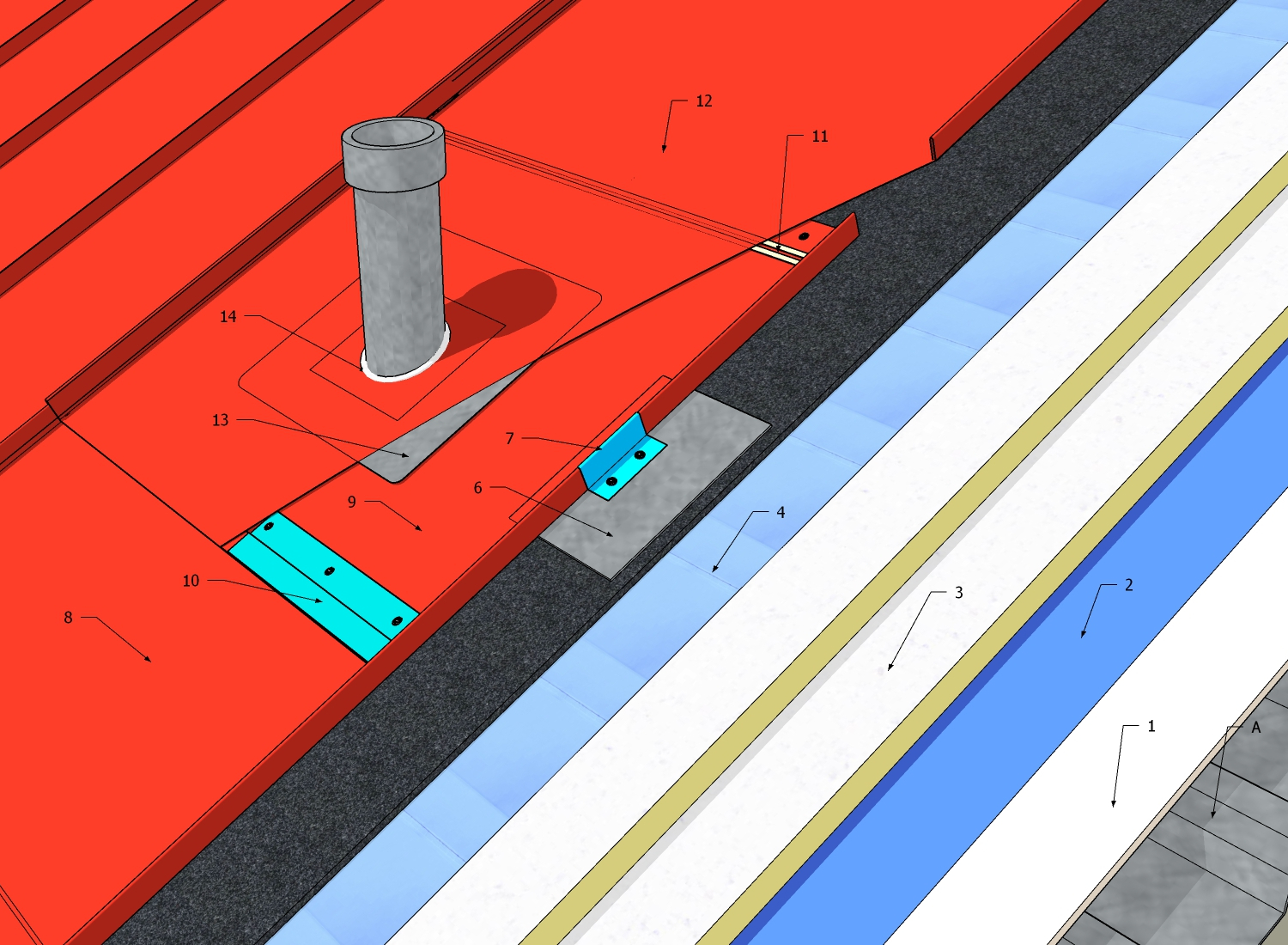

ASM Cylindrical Penetration (Split Panel Flashing)

ASM Cylindrical Penetration (Split Panel Flashing)

Revision as of 17:54, 10 August 2016 by James Klassen (talk | contribs)

1 WORK INCLUDED

- (1) Underlayment

- The type of underlay required is determined by roof slope.

- (2) Slip Sheet

- Recommended over asphaltic underlays and / or as required by metal roof panel manufacturer.

- (3) Valley Metal Panel

- Lower, installed prior to the pipe flashing, cut hole large enough to allow for movement. Extend 400 mm (16") upslope beyond the pipe.

- (4) Flashing

- Flange set in two continuous beads of accepted caulking.

- (5) Spaced Cleat

- Cleats, set in accepted caulking, spaced 50 mm (2") and fastened with compatible non-corrosive flat head screws.

- (6) Architectural Metal Roof Panel

- Upper, installed after installation of pipe flashing. Cut hole for pipe penetration and turn panel end under to accommodate cleats.

- (7) Settle Cap

- Material must match flashing material.

- (8) Caulking

- Bead of caulking tooled into transition between metal roof panel and flashing.

- (9) Sealant Tape

- Two rows of sealant tape or acceptable caulking.

- (10) Drag-load Fasteners

- Compatible non-corrosive fasteners.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.