Draft CD 6

Draft CD 6

Revision as of 23:11, 10 February 2020 by James Klassen (talk | contribs) (Created page with "{| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span sty...")

| RoofStar Guarantee Standards are blue-linked |

SBS Details

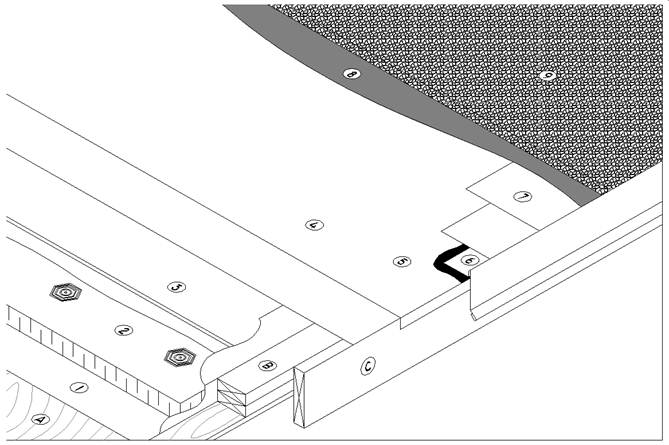

1 WORK INCLUDED

- (1) Air or Vapour Control Layers

- If required by design authority

- (2) Insulation

- See available insulation products in the Accepted Materials section of this Manual.

- (3) Insulation Overlay

- Where required.

- (4) Primary Membrane and Membrane Protection

- Mechanically fasten to outside face of fascia (C).

- (5) Mastic

- Trowel coating of compatible mastic.

- (6) Metal Edge/Gravel-stop Flashing

- Flashing must have a minimum 100 mm (4") flange that extends onto roof base membrane. A flush termination is permissible and more common than a "gravel stop" (see 10.3.5.2 Metal Edge Terminations for application standards). Where a gravel-stop upstand is desirable (shown in the detail at left), it must not be higher than 25 mm (1") high.

- Embed the flashing in mastic and mechanically fasten alternately between centre and edge of flange at 100 mm (4") O.C. Lengths of flashing may be joined end-to-end with an overlap no less than 100 mm (4").

- (7) Membrane Flashing

- Asphalt and gravel roofing systems, 2 overlapping plies of a minimum 2 mm reinforced SBS modified bitumen base sheet. For flexible membrane systems, refer to manufacturer’s application details and RoofStar Guarantee Standards.

- (8) Asphalt

- For asphalt and gravel built-up roofing systems only.

- (9) Gravel

- For asphalt and gravel built-up roofing systems only.

2 RELATED WORK BY OTHERS

- (A) Acceptable Supporting Deck Structure

- (B) Wood Blocking

- (C) Wood Fascia

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

Back to RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems