Notes to EPDM Standard

Notes to EPDM Standard

Revision as of 15:13, 1 November 2024 by James Klassen (talk | contribs)

Division B - Standards

Notes to RGC Standard for EPDM Membrane Roof Systems

(Notes are explanatory and non-binding, each provided to support the requirements, guiding principles and recommendations of the Standard.)

Notes to Part 1

A-1.1.2.4. Quality Assurance

- An independent Observer plays a key role in every project for which a building owner has paid a fee to qualify it for a RoofStar Guarantee. Each Observer is independently trained as a professional and therefore understands the responsibilities that typically encompass the role. However, there are additional responsibilities that come with the designation "Accepted Observer", which is particular to the RoofStar Guarantee Program. To ensure that Observers fully understand the purpose, scope, and direction of the Program, the RGC provides training for Observers, specifically geared to the RGC's Program. The status of "Accepted" does not mean the Observer is contracted, or endorsed, by the RGC; it means that the Observer has achieved a satisfactory level of competency with the RoofStar Guarantee Program, required by the RGC to be qualified to provide Quality Assurance observations (limited inspections) on behalf of an Owner.

- Where an Observer or Observer Firm also engages in the work of consulting (providing advice and design work), the work of the consultant is considered by the RGC to be wholly separate from the role of Observer.

A-1.1.3.1. Permitted Roof Systems

- Designing a good roof begins with the end in mind and an answer to the essential question, “What purpose will the roof serve?” For example, the roof may

- simply weatherproof the building interior,

- provide a location for building equipment and services, or

- support liveable (amenity) spaces.

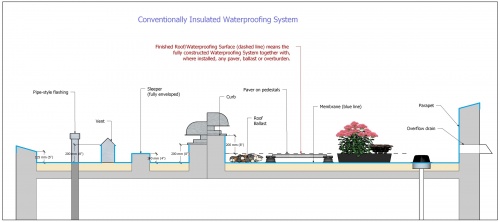

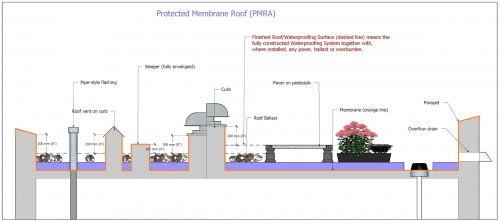

- The Finished waterproofing system is defined by whatever is placed on the membrane, which may be insulation, ballast, pavers or overburden. These materials will displace water and therefore affect the height of membrane flashing needed to prevent water ingress. The definition of Finished waterproofing system is illustrated below in Figures 1.3.2-1 and 1.3.2-2. See also Article 1.1.1.4., "Definitions".

A-1.1.3.3. Membrane Integrity Scans

- An integrity scan is performed after the installation of the roof waterproofing system, before any overburden, equipment or amenity space is installed on top of it. An integrity scan typically uses low-voltage electrical current to detect even the smallest breaches in the roof membrane, but some waterproofing materials may require the use of other technologies to verify the roof system’s integrity. Therefore, Design Authority should specify the appropriate technology, keeping in mind the limitations of each scan and detection methodology, and of the membranes that are specified.

- Neither an integrity scan nor an Electronic Leak Detection (ELD) system are considered Accepted Materials, but firms that provide these services are nevertheless specifically recognized and approved by the RoofStar Guarantee Program.

A-1.1.3.3.(5) Flood Testing

- Flood testing is a method employed to visually check a membrane for leaks; it involves flooding a finished membrane area to a depth not exceeding 100 mm (4"), and leaving the area flooded for a standard period (24 to 48 hours). The test is predicated on the assumption water under hydro-static pressure will present on the underside of the membrane if any breaches are present through which even a molecule of water can pass. ASTM D5957, Standard Guide for Flood Testing Horizontal Waterproofing Installations, is the commonly accepted method for conducting membrane integrity flood tests.

- Protected roof systems are best suited for flood testing. The membrane is usually installed directly above the roof deck, and if water leaks through the membrane, the leak may be seen from below (this is less likely on a concrete deck, simply because water will not present unless it has a pathway through the deck (a crack, for example); and even then, water may not present for several days after the conclusion of the test. Conventionally insulated roof systems are not good candidates for flood testing, for several reasons. First, the integrity of an air or vapour membrane (installed at or near deck level) will likely prevent water from presenting, in which case no one will ever know if the membrane leaked or was water-tight. Second, if the membrane is not water-tight but a leak cannot be detected visually, water entering the roof system could cause considerable damage to roof system components such as insulation.

A-1.1.3.4. Electronic Leak Detection

- Electronic Leak Detection (ELD) utilizes low-voltage electrical current, typically conducted through wires installed in a grid pattern. ELD technologies are used in response to a leak, to isolate its location in order to minimize investigation time and material removal. This can benefit a building owner who will have to bear the costs of demolition or overburden removal when the standard limits of coverage afforded by the RoofStar Guarantee are exceeded by the Project design and construction. ELD technologies may be passive (installed but not monitored) or actively monitored (by the installer, through real-time data collection).

A-1.1.3.5. Hot Works

- When any portion of a waterproofing system is installed with heat, the work is classified as Hot Works. Some tools used in the course of Hot Works can ignite combustible materials, and some building environments are more sensitive to fire than others, such as a building containing or in close proximity to flammable liquids. Hot works may occur during

- tear off (sparks).

- deck preparation (drying wet surfaces).

- cold temperatures (warming materials or surfaces).

- equipment use (sparks within electrical tools, or from cutting, drilling, or grinding metal, concrete, stone, or other hard surface products).

- membrane installation (with the means of a kettle, hot-air welder, or open flame torch).

A-1.1.4. Alterations and Additions

- As a roof ages, is neglected or is damaged, it may lose its ability to perform reliably and effectively, necessitating replacement. Replacement roofing, also referred to as "re-roofing," whether made in whole or in part, should be undertaken with the Quality Assurance and Quality Control provided for under the RoofStar Guarantee Program. Regardless of the approach to replacement roofing, the existing deck structure must meet the pullout resistance rating for mechanical fasteners and must be capable of supporting all dead and live loads. Furthermore, the deck must be capable of supporting any additional dead loads of the new roof system.

- Three types of replacement roofing are contemplated and permitted (with varying degrees of limitations and conditions) under the RoofStar Guarantee Program:

- System replacement - removal and replacement of all roof system components, except for the supporting deck structure.

- Membrane replacement – removal and replacement of the roof membrane, while retaining existing roof system components (i.e., insulation, ballast).

- Recovering - installation of a new membrane over an existing membrane, while retaining some or all of the other roof system materials (NOTE: Recovering is permitted only with a written Variance issued by the Guarantor).

- Qualifying and construction conditions and limitations for each of these replacement options are outlined in Subsection 1.1.4. Other conditions and limitation may be determined by the Guarantor subject to the nature and specifications of the replacement roofing project.

A-1.1.4.4 Membrane Recovering

- When membrane replacement is not practical, membrane recovering is an acceptable method for renewing the weatherside surface of a waterproofing roof assembly when most if not all of the other components (insulation and the air barrier) remain undamaged and undisturbed. It does not require the removal of any roof system components, but it does require an assessment beforehand, to determine the integrity of the existing roof system. A RoofStar Guarantee cannot respond to existing water inside the system, which is why they must be surveyed for moisture by a qualified professional, and the report provided to the Guarantor as part of the submission for a Variance. However, because the requirements in Part 3 apply to both new and replacement roofing, securing new materials on top of existing materials becomes challenging and critical .

- Every roof assembly constitutes a chain of connected parts and that 'chain of connectivity' is predicated on the integrity of the bonds between each adjoining component. Because aged adhesives in conventionally insulated roof assemblies may not provide the hold-down strength they once did when they were new, the RGC requires the Design Authority to conduct adhesion tests to confirm that the existing assembly exceeds the Code requirement for design loads. If that cannot be achieved, mechanical fastening is required to provide a direct connection to the structural deck .

- Cutting the existing membrane is also necessary to relieve diaphragm-like tension that could distort the new roof system, particularly at the perimeter. It also allows any existing moisture in the roof system to move around and prevents the existing membrane from acting as an intermediate vapour retarder that could adversely affect the performance of the recovered roof system .

A-1.3.2.2. Workmanship

- While integrity and functionality of a new roof or grade-level waterproofing is the foundation of a RoofStar Guarantee, it is no less important to ensure that the finished project exhibits excellent workmanship.

Notes to Part 2

A-2 Scope and Application of Part 2

- Part 2 addresses deck and wall materials, deck slope, deck and wall conditions, and the methods by which intersecting systems such as electrical wiring can be executed safely and in alignment with the interests of the Guarantor. It does not address construction or installation of decks and walls, which is the work of other trades. For the preparation of a roof deck to render a deck or wall suitable for roofing, refer to Part 9 and Part 10, in the articles pertaining the substrate preparation.

A-2.1.3.1. General Requirements for Roof Slope

- Roof slope may be achieved either by designing the roof structure with sloped decks ("structural slope"), or by introducing slope with tapered board insulation (built into the roof system).

A-2.1.3.1.(4) Sufficient Slope

- The term, "sufficient slope", is a reference to a nominal value applied to the primary sloped planes of a roof and is measured from the highest point on a slope to the lowest point, at the roof drain or sump edge (the term does not refer to the slope of valleys). It is also generally a subject that concerns roofs with an exposed membrane (not covered with ballast or an overburden), and generally does not apply to protected roof systems. This definition of "sufficient slope" allows for the possibility of intermittent deflections in the drainage plane, particularly in places where the underlying deck may have settled over time.

- While insufficient slope may be the suspected cause of rainwater retention (pooling) on a roof surface (commonly referred to as "ponding"), there are other factors beyond slope, such as local climate and roof maintenance, that contribute to retention. The accumulation of debris on a roof is a common reason for ponding. Very little debris (often leaf litter) is necessary to block a drain, and most ponding occurs around roof drains. Routine roof maintenance will solve most roof ponding problems. However, while maintenance is within the control of the building owners or occupants, climate is not, making it difficult, if not impossible, to determine what is "reasonable". Temperature, air movement, and relative humidity (rh) all affect the rate of evaporation. As long as the roof is debris-free, some ponding will not adversely affect a roof membrane.

A-2.1.5.1. Steel Roof Decks

- Steel decks are constructed of light gauge (usually 22, 20, or 18 gauge) cold-rolled steel sections (panels) that are usually galvanized. In cross-section the panels are ribbed, with the ribs usually spaced at 150 mm (6") O.C. The ribs provide the strength and rigidity of the panels. Steel decks are generally supported by open-web steel joist framing and are welded or mechanically fastened to the framework.

A-2.1.5.2. Concrete Roof Decks

- Concrete decks to which a roof system may be applied include

- Cast-in-place.

- Pre-cast panels.

- Pre-stressed panels.

- Lightweight.

A-2.1.5.3. All Wood Roof Decks

- Wood is a common roof deck construction material that has been used for many years because of its economy, ease of fabrication, lighter construction, and ready availability. Acceptable wood roof decks may include (without limitation)

- wood board (tongue-and-groove, ship-lapped, or splined boards or planks that typically range in thickness from 19 mm to 89 mm (nominal 1" to 4"). Wood board decks may also include Mill Decks which are also called Nail-Laminated Timber decks. These are constructed with a single layer of dimensional boards (dimensions can vary), placed on edge and spiked together to form a Mill Deck. The thickness of the boards is determined by the anticipated loads and spacing of roof joists or trusses.

- plywood (exterior type plywood mechanically fastened to the roof framing).

- non-veneered (oriented strand board, waferboard, etc.).

- laminated timber (typically comprised of crossing layers of dimensional solid wood material, laminated to form a thick, dimensionally stable slab strong enough to support significant structural loads).

A-2.1.5.4.(1) Plywood Roof Decks

- There are eight (8) exterior grades of plywood used in Canada, and the Canadian Wood Council (CWC) identifies and explains each of them in their published article, "Plywood grades" (https://cwc.ca/wp-content/uploads/2019/03/Plywood-Grades.pdf). Because grades vary, it is incumbent upon the Design Authority to specify the correct grade for roof decking.

A-2.1.5.4.(3) Suitability of Plywood Roof Deck

- The roof membrane, when installed to the applicable RGC Standard, will repel water and keep the structural roof deck dry, but if the membrane is damaged and water leaks through undetected, untreated plywood decks exposed to water for a prolonged period may succumb to decay, which can compromise deck integrity. To protect against accidental leakage, plywood decks and adjoining wall or curb surfaces for vegetated roof assemblies should be constructed with pressure-treated plywood. Many membrane roof assemblies tested on plywood stipulate a minimum deck thickness of 15.88 mm (5/8”) (See Article 3.1.3.3. on the subject of Tested Assemblies). When the existing plywood deck is untreated, it should be covered with a suitable overlay (i.e., treated tongue-and-groove plywood, concrete board, etc.). To ensure that water does not leak through the joints, tape the joints with a self-adhered material that is compatible with, and will adhere to, the overlay board .

- Properly securing decking or a deck overlay will require the help of a registered professional engineer, who will also ensure that fasteners will be compatible with the plywood treatment. Deck overlays form part of the roof assembly and so their securement is typically governed by what has been tested .

- For more about pressure-treated plywood, refer to the Canadian Wood Council. For a helpful guide on fastener compatibility, see the BC Housing Builder Insight document, “Compatibility of Fasteners and Connectors with Residential Pressure Treated Wood”.

A-2.1.5.5. Overlays for Mass Timber Decks

- An overlay may be required by the manufacturer for these types of wood decks to protect membranes from wood sap, deck surface irregularities, and protruding fasteners.

A-2.1.7. Walls

- Walls and roofs intersect either directly (where the wall structurally connects to the roof structure, so that both move together), or indirectly (where the roof structure and the wall structure are independent of each other, so that the movement of one does not affect the other). These locations require an expansion joint.

A-2.1.8. Electrical Cables and Boxes

- Electrical boxes, fixtures, and electrical wiring (exposed or protected inside conduit) installed inside, on top of, or beneath a roof assembly may present hazards for roofing workers and building occupants and may interfere with the roof design.

- Many Tested Assemblies (roof assemblies tested under controlled conditions) rely on mechanical fasteners to secure some or all materials. Roof fasteners (which are self-drilling so they can penetrate steel decking) are capable of penetrating even the most rigid electrical conduit. When roofing screws contact an energized electrical system, workers can be shocked, sometimes with lethal consequences. Furthermore, electrical conductors damaged by roofing screws may not trip fault protection devices which generally do not respond to high-resistance faults. High-resistance electrical faults have been linked to numerous structural fires, which sometimes occur years after conductors were damaged. For these reasons, separating the electrical service from the roof assembly is critical.

- Electrical conductor damage is not a problem exclusive to new construction. As roofs wear out and require partial or full replacement, mechanical fastening is often the only way by which new roof materials can be secured to the structural roof deck, to comply with the Building Code. When electrical systems are hidden by existing roof system materials, the design and construction of a replacement roof may be exceedingly difficult to execute.

- Rule 12-022 of the "2021 Canadian Electrical Code, Part I", now prohibits the installation of “cables or raceways” within a roof assembly. Rule 12-022 is reprinted below (the term “roof decking system” used in the Rule has the same meaning as roof assembly used by ASTM International (ASTM D6630-08, "Standard Guide for Low slope Insulated Roof membrane Assembly Performance"), and by this Standard):

- 12-022 Cables or raceways installed in roof decking systems

- 1) Cables or raceways installed in accordance with this Section shall not be installed in locations concealed within a roof decking system, where the roof systems utilises screws or other metal penetrating fasteners.

- 12-022 Cables or raceways installed in roof decking systems

- 2) Notwithstanding Subrule 1) the following circuits shall be permitted for installations in locations concealed within a roof decking system:

- a) Class 2 circuits in which the open-circuit voltage does not exceed 30 V; and

- b) embedded trace heat.

- 3) Where wiring is concealed within the roof deck system in accordance with Subrule 2), a warning label shall be installed

- a) at all permanently installed roof access points where provided; and

- b) in a conspicuous location in the roof area where the cabling is installed.

- 2) Notwithstanding Subrule 1) the following circuits shall be permitted for installations in locations concealed within a roof decking system:

- While Rule 12-022 permits the installation of cables and raceways within a roof system that does not utilize "screws or other metal penetrating fasteners", doing so is inadvisable; unlike electrical systems that are more or less permanent, roof systems must be renewed, usually multiple times over the course of a building's expected service life. Often, when the roof system is only partially renewed (for reasons of economy, or to limit the amount of material entering the waste stream), mechanical fasteners offer the best option for securing new materials to those left in situ. Obviously, electrical systems located anywhere close to the roof assembly pose high risks to both the Contractor during construction and may introduce a fire risk to building occupants later (for more on this subject, see the Information Centre in Division E). Providing considerable separation between electrical systems and the roof assembly, and ensuring that electrical services to rooftop equipment utilize purpose-made penetrations that can be sealed into the roof system, will serve the Owners well for the service life of the building.

- Rule 12-022 is a national code requirement directly resulting from a years-long endeavor by the RCABC, provincial adoption of the Canadian Electrical Code, Part I may be delayed because of the British Columbia code cycle. Nevertheless, the Design Authority is advised to adopt the requirements and prohibitions of the national Code, and to also adopt the following requirements for new construction or replacement roofing, as they apply.

Notes to Part 3

A-3.1.1.1. Scope

- Wind exerts tremendous forces on a roof system, regardless of roof type. While wind is commonly experienced as a “pushing” force, wind also generates “negative” (pulling or “uplift”) forces, particularly on flat roofs. These powerful forces can, if the roof system is poorly secured to the building’s structural elements, detach a portion or all of a roof system from the building.

- The Code refers to these calculated forces as Specified Wind Loads, which act in concert with the “responses of the roof system…[and therefore] are time-and-space dependent, and thus are dynamic in nature.” (CSA Standard A123.21, "Standard test method for the dynamic wind uplift resistance of membrane-roofing systems" (latest edition), 4.1). Because of this dynamic interplay between loads and a building’s structural capacities (the load paths between the roof system and other structural elements of the building), the Design Authority must design a roof capable of effectively absorbing and mitigating Specified Wind Loads.

- As stated earlier, the calculation of Specified Wind Loads falls under "British Columbia Building Code", Division B, Subsection 4.1.7., "Wind Loads", while the securement of the roof components system to resist Specified Wind Loads is governed by the "British Columbia Building Code", Division B, Article 5.2.2.2., "Determination of Wind Load".

A-3.1.1.1.(4) Tested Assembly

- It is important to note that CSA-A123.21 is a test method developed only for conventionally insulated roof systems constructed with sheet membranes and does not apply to other sheet membrane roof systems, or to roof systems constructed with other waterproofing materials such as liquid-applied membranes.

A-3.1.1.2. Intent

- In December 2018 the Province of British Columbia released a revised edition of the "British Columbia Building Code" (the "Code"), based on the 2015 "National Building Code of Canada". The 2018 Building Code includes a considerable expansion of the requirements in Division B, Part 4 (see "British Columbia Building Code", Division B, Subsection 4.1.7., "Wind Loads") applicable to the loads exerted on a roof system by wind. The careful reader will note that these Part 4 requirements apply to all Part 3 buildings and to some Part 9 structures.

- While the expansion of Part 4 addresses the calculation of dynamic wind loads experienced by a roof assembly, Part 5 ("Environmental Separation") specifies how a roof system should be secured to resist Specified Wind Loads (see the "British Columbia Building Code", Division B, Article 5.2.2.2., "Determination of Wind Load").

- Article 5.2.2.2. of the Building Code applies almost exclusively to conventionally insulated roof systems and is specifically oriented to sheet membrane roof systems. While sheet membrane conventionally insulated roof systems are prolific and perhaps the most common type of waterproofing roof system, the Building Code offers little guidance for other roof types, including uninsulated roof systems, liquid membrane systems, systems insulated above the membrane (referred to as “inverted” or “protected”), and steeply sloped roofs (greater than 1:6, or 2" in 12"). This Standard incorporates design and construction guidance, even where the Code appears to offer little or no support.

- Proper securement of the roof system, to resist wind uplift loads, is good practice. It also fulfills the design and construction objectives of the Code, to guard public safety, and it supports the design objectives of the RoofStar Guarantee Program, to keep weather outside of the building. In this Part, the reader will find explanatory notes and aids in the design and construction of a roof intended to be Code-compliant.

A-3.1.3.1. Responsibility for Design

- See also the "British Columbia Building Code", Division B, Article 2.2.1.2., "Structural Design", and the "British Columbia Building Code", Division B, Part 5, Notes to Part 5: Note A-5.2.2.2.(4).

A-3.1.4.1. Securement Against Specified Wind Loads

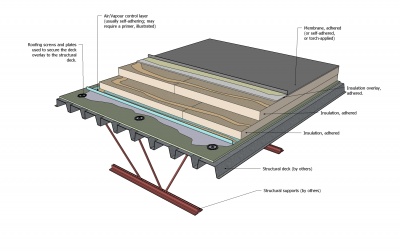

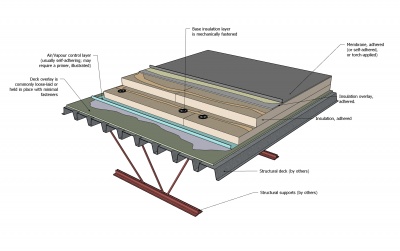

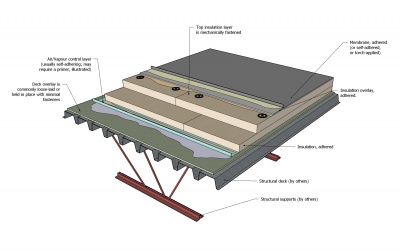

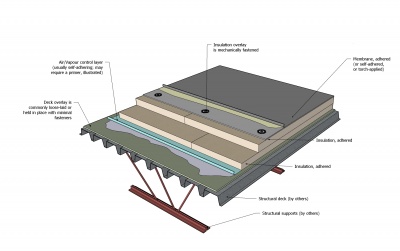

- The acronyms ("AARS", "PARS", and "MARS") are derived from the test method CSA-A123.21, "Standard test method for the dynamic wind uplift resistance of membrane-roofing systems" (latest edition). Mechanically Attached Roof Systems ("MARS") refers to roof systems that are secured through the membrane with screw fasteners and plates. Adhesive Applied Roof Systems ("AARS") denote roofs where all the constituent layers are adhered to each other, and to the supporting roof deck. However, Partially Attached Roof Systems ("PARS") can be constructed at least four ways since the layers secured by mechanical fasteners or adhesives is largely variable. The illustrations below show the possibilities, all of which may be tested by a manufacturer to determine the best possible resistance to wind loads.

A-3.1.4.2. Specifying a Tested Assembly

- Tested Assemblies are roof assemblies that have been selected by the membrane manufacturer, installed on a specific deck type, secured using one of three systems, and tested by an independent certified laboratory to determine the limits of the assembly’s ability to resist negative wind pressure (loads), or ‘wind uplift’. Each of the three methods is expressed with an acronym:

- "MARS", or "Mechanically Attached Roof Systems" – these systems are held in place only with mechanical fasteners that are installed at the membrane layer.

- "PARS", or 'Partially Attached Roof Systems" – both mechanical fasteners and adhesives are used as a hybrid method of securement; the membrane is always adhered, using an applied adhesive or heat-welding.

- "AARS", or 'Adhesive Applied Roof Systems" – these are membrane roofs secured only with adhesives or heat-welded components.

A-3.1.6.1. Securement of Ballasted Roof Systems

- Ballast used on protected membrane roof systems performs at least two critical functions. First, working in concert with a filtration material that holds insulation panels in their respective positions (rafting), ballast resists insulation flotation in the event water accumulates on the roof. Secondly, ballast resists the effects of wind that can displace lightweight roofing insulation and filtration materials. Each requires the appropriate weight by volume of ballast.

- ANSI-SPRI RP-4, "Wind Design Standard for Ballasted Single-ply Roofing Systems", provides some guidance, but its methods are based on wind speeds, not wind pressures; pressures, not wind velocity, are used in the applicable Canadian Codes. Therefore, the registered professional skilled in the work of Part 4 (Div. B) should use the ANSI/SPRI standard in conjunction with wind speeds listed in Table C-1, using wind loads calculated in accordance with Subsection 4.1.7. of Division B (see the commentary on Wind Effects in Division B, Appendix C). Where ballast is used to resist other structural loads in a building, the registered professional is responsible to review these, particularly in replacement roofing.

- Technical Bulletin Volume 40 published by the Canadian Roofing Contractors Association (CRCA) provides some guidance for using the ANSI/SPRI standard to determine ballast requirements. Note that the exposure categories are different from those used in the Building Code. Use the appropriate ballast size and weight guidelines based on roof zones and zone dimensions.

- The ballast values published in Table 3.1. of Article 3.1.6.1. in the RoofStar Guarantee Standards are minimum values that will address many roof designs where the roof deck is air-impermeable (CRCA Technical Bulletin, Vol. 40). If the roof deck is air-permeable, or if flow control drains are present (these may retain water on the roof, thereby introducing added buoyancy), the design may require higher ballast weights (and correspondingly higher volumes). Ensure the structural design of the building can accommodate the necessary ballast weight, together with anticipated live loads, including those loads imposed on the building during construction.

- While gravel ballast is commonly used on protected membrane roof systems, wind scour can dislodge rocks from the roof, rendering them a public safety hazard. Consequently, the designer may need to design a roof with higher parapets (See Article 10.1.4.1., "Parapets"), or choose a different ballast material, such as concrete pavers.

- See also CRCA Technical Bulletin Volume 35 on ballast design requirements for protected membrane roofs.

A-3.1.7.2. Partial Roof System Replacement

- When a roof system is partially replaced, it is incumbent upon the Design Authority to determine the reliability of the materials left in situ, to which new materials will be secured. Often, the integrity of the connections between constituent materials in an in-situ assembly may be difficult if not impossible to ascertain, so that adhering new materials seems dubious at best (Ref. the "chain of connectivity" concept (NRC), which simply refers to both the "adhesive" and "cohesive" properties that bind adjacent materials together in a roof assembly). When determining the integrity of existing materials connections is difficult or impossible, using mechanical fasteners may be the best reliable method for securing new materials to an existing roof assembly.

A-3.2.1.1. Substituting Materials Used in a Tested Assembly

- Tested Assembly values (Dynamic Uplift Resistance) are predicated on a specific combinations (system) of materials. Each material in the system possesses unique "cohesive properties" (internal strength and integrity) and is linked to the adjacent material in a particular way that may depend on a material’s unique "adhesive properties".

- The substitution of material components in a Tested Assembly is not contemplated by CSA-A123.21, but Annex F (a non-mandatory part of the CSA Standard, included at the back of the Standard document for information only) includes three decision processes for "MARS", "PARS" and "AARS" assemblies, to guide the Design Authority when a substitution is desirable or necessary (Ref. CSA-A123.21, "Standard test method for the dynamic wind uplift resistance of membrane-roofing systems", Annex F (informative) Component swap flow diagrams). Use Annex F as a basis for guidance when material substitution is necessary.

Notes to Part 4

Notes to Part 5

A-5 Deck and Wall Overlays

- This Part addresses materials that are acceptable as overlays used to render a deck or wall surface suitable for roofing. This Part supports the substrate preparation requirements in Parts 9 and 10.

A-5.1.3.1. Required Use of Overlays

- A roof deck overlay (also called a system underlay) is installed as part of the roof system (usually uninsulated or conventionally insulated) , on the top surface of the roof deck but beneath other roofing materials. These products are most commonly affixed to steel decks to provide an even , level surface for the roof membrane, to support air or vapour control layers, or to serve as a thermal barrier between the roof deck and combustible insulation. Roof deck overlay materials may also be applied to other types of supporting deck structures, depending on the roof design criteria.

- The thickness of a deck overlay may be determined by the Fire Code Consultant or be pre-determined in a Tested Assembly report, but when it is not, the Design Authority may be tempted to specify a thin product as a cost-saving measure. Before doing that, the Design Authority should consider two key issues. First, the thin overlay must provide more than minimum wind uplift resistance for the entire roof assembly. Therefore, select the appropriate deck overlay thickness based on the material's properties, in consultation with the registered professional skilled in the work of calculating wind loads and designing the securement of the roof assembly .

- Second, consider how long the overlay and the materials that cover it will remain exposed to construction activity before the rest of the roof system is installed (sometimes, the deck overlay and an applied air/vapour barrier material serves as a "temporary roof" structure to permit phased construction of other building elements). Gypsum-based overlays may be more vulnerable than other materials to crushing, especially where the boards are thin and span the gaps between steel deck flutes. Damage from construction activity may compromise the overlay's expected performance properties. When phased construction is expected and the deck overlay and a membrane may be left exposed for more than a few days or a week, consider specifying a thicker or more robust overlay panel .

Notes to Part 6

A-6 Air and Vapour Controls

- Part 6 is a boilerplate wording included in every Standard of the RoofStar Guarantee Program, regardless of whether or how air and vapour controls are used in a roof assembly.

- Air and vapour controls, whether manufactured as sheet products or as liquids, form a critical component of the suite of building enclosure systems used to regulate the movement of air and water vapour in and out of the building. Because continuity is critical not only within an assembly but also between assemblies, performance of air and vapour control materials is not covered by the RoofStar Guarantee; the RoofStar Guarantee Program is limited to the scope of a roof system, and therefore it has no control over the construction or performance of adjoining assemblies, such as walls, which may adversely impact the performance of the roof system. Nevertheless, the choice of materials used in a roof system is still critical for its performance. Therefore, this Part prohibits certain materials because, from a constructability standpoint, they are difficult to seal (to achieve continuity) and are often fragile and prone to puncture during construction. Furthermore, this Part includes both design and construction requirements intended to achieve continuity, since the transfer of air and the movement of water vapour into the roof system can produce false leaks that undermine the objectives of the Standard.

A-6.1.1.1. Scope

- Air and vapour control layers, along with thermal barriers, water resistive barriers and water-shedding surfaces, serve to separate the outside environment from the interior environments of a structure. Continuous air control layers are perhaps the most critical. Codes in each jurisdiction, and the "2020 National Energy Code of Canada for Buildings" (NECB), require the selection and proper installation of “a continuous air barrier system comprised of air-barrier assemblies"..."to control air leakage into and out of the conditioned space” ("National Energy Code of Canada for Buildings", Part 3, Article 3.2.4.1., "General").

- Air control layers regulate and often prohibit the “flow of air through the building enclosure, either inward or outward” (Guide for Designing Energy Efficient Building Enclosures, Homeowner Protection Office). Controlling air flow into and out of conditioned spaces affects the performance of “thermally efficient enclosure assemblies” (ibid), impacts the potential for condensation in between materials, and directly influences rain water penetration of the building envelope.

- Vapour control layers regulate or prohibit the movement of water vapour from one space to another by means of diffusion. Consequently, these control layers are referred to as either vapour-permeable or impermeable. Diffusion is a slow process, in contrast to air movement, and its regulation is not always mandatory or even desirable.

- Any references in this Manual to installation methodologies, and any construction details that show air and vapour control layers, are merely illustrative and not prescriptive. Installers of continuous air and vapour control layer systems are urged to understand and comply with best practices for their application.

A-6.1.3.1. Responsibility for Design

- Air and vapour control layer performance is not part of the RoofStar Guarantee, and air and vapour control materials are not listed in Division C.

- In some roof assembly designs, the required underlayment may serve as an air control layer, vapour control layer, or both; this is dependent upon the properties of the material to be used and will be subject to the designer’s modelling of the assembly. Consult the Technical Data Sheets for suitable materials.

A-6.2.1.2. Prohibited Materials for RoofStar Guarantee

- Constructability, and resistance to damage, heat, and to solvent-based products, are key properties of air and vapour control materials. While the RoofStar Guarantee does not extend coverage to air and vapour control materials, or to their performance (Ref. Note A-6, "Air and Vapour Controls"), leaks through or past damaged or poorly sealed materials can adversely affect the performance of the guaranteed roof system. For this reason, both polyethylene plastic sheet products and bitumen-impregnated kraft paper are not permitted in a roof intended to qualify for a RoofStar Guarantee; both materials are easily damaged (punctured) during construction, and proper sealing of each material to itself and to adjoining materials is difficult.

Notes to Part 7

A-7.1.3.1 Responsibility for Design

- Insulation materials rely on various standards for the determination of thermal resistance, which means that not all data can be easily compared. Furthermore, not all insulation products perform with consistent thermal resistance as temperature changes, and some insulation performance declines with age. Therefore, refer to the "Long-term Thermal Resistance" (LTTR) for each insulation product, in relation to the product's placement within the roof assembly and the anticipated outside and interior climates of the building.

- Also see the "British Columbia Building Code", Division B, Part 10 (Ref. Div. B, Section 9.25., "Heat Transfer, Air Leakage and Condensation Control" for structures governed by Part 9), together with relevant requirements in Division A and Division C of the Building Code.

A-7.1.3.4. Effective Thermal Resistance and Layering

- In warm seasons, the roof surface may reach temperatures higher than 85°C (185°F), affecting the performance and stability of some insulation. Consequently, the requirement which limits panel size in single-layer applications ensures that inevitable gaps between adjacent panels are kept to a minimum. Combining insulation types in a roof system may help mitigate these temperature swings and the consequence of thermal contraction. The Design Authority therefore must consider these variables when specifying materials and their installation.

- The "Long-Term Thermal Resistance" (LTTR) measurement of closed-cell insulation materials remains the standard by which insulation performance is measured. Published R-values should reflect the LTTR of the material. In Canada, two principal standards apply to the accurate measurement of thermal resistance: CAN/ULC-S770 ("Standard Test Method for Determination of Long-Term Thermal Resistance of Closed-Cell Thermal Insulating Foams") and CAN/ULC-S704.1 ("Standard for Thermal Insulation, Polyurethane and Polyisocyanurate, Boards, Faced").

A-7.1.3.4.(3) Thermal and Dimensional Stability of Insulation Panels

- In warm seasons, the roof surface may reach temperatures higher than 85°C (185°F), affecting the performance and stability of some insulation. Consequently, the requirement which limits panel size in single-layer applications ensures that inevitable gaps between adjacent panels are kept to a minimum. Combining insulation types in a roof system may help mitigate these temperature swings and the consequence of thermal contraction. The Design Authority therefore must consider these variables when specifying materials and their installation .

- While multi-layering insulation is required when the cumulative thermal resistance of all insulation exceeds RSI-2.64 (R-15), it is important to note that most insulation types naturally experience dimensional change in all 3 planes as outside temperatures and sun exposure change throughout the day (mineral fibre insulation being the general exception). The degree of expansion or contraction directly corresponds with the thickness of the panel; the greater the thickness and panel size, the larger the movement. Considerable movement may create unexpected issues with the roof; shrinkage and resulting gaps between insulation panels may introduce thermal loss, and movement that telegraphs to the supporting roof surface may produce membrane wrinkling. To reduce the consequences of thermal movement, the Design Authority should consider specifying maximum layer thickness; any leaks attributed to roof system movement are excluded from coverage under a RoofStar Guarantee .

- The "Long-Term Thermal Resistance" (LTTR) measurement of closed-cell insulation materials remains the standard by which insulation performance is measured. Published R-values should reflect the LTTR of the material. In Canada, two principal standards apply to the accurate measurement of thermal resistance: CAN/ULC-S770 ("Standard Test Method for Determination of Long-Term Thermal Resistance of Closed-Cell Thermal Insulating Foams") and CAN/ULC-S704.1 ("Standard for Thermal Insulation, Polyurethane and Polyisocyanurate, Boards, Faced") .

A-7.1.4.2. Protection of Heat-sensitive Insulation

- Heat-sensitive insulation can be distorted and even damaged when absorbed solar radiation raises the temperature of the insulation above its published maximum service temperature rating (usually 70 - 75°C). Severe damage can reduce the thermal resistance of the insulation system; damaged panels have been known to contract, causing depressions and increasing gaps between adjacent panels.

- The requirement to use a layer of heat-resistant insulation on top of heat-sensitive insulation is based on a mathematical modeling of the buffering effects of different overlay strategies. While modeling showed some insulation overlay panels reduced some absorbed heat, none reduced heat below the service temperature of the insulation, and none provided sufficient margin to allow for high-heat weather events. Only heat-resistant insulation measuring at least 50 mm (2") thick offered the necessary level of protection to prevent insulation damage.

A-7.2.2.3. Polyisocyanurate Insulation

- Since September 1, 2010, the RGC has excluded organic-faced polyisocyanurate insulation from the RoofStar Guarantee Program, because of moisture-induced cupping and curling attributed to the composition of the facer material. Only fibre-glass or acrylic facers are accepted by the Guarantor for use on roofs qualifying for a RoofStar Guarantee.

Notes to Part 8

A-8.1 Design

- Insulation overlay boards are installed in most conventionally insulated systems to

- protect heat-sensitive insulation materials from damage by heat and flame.

- protect insulation materials from accidental impact.

- provide dimensional stability to the roof system.

- distribute dead loads from heavy overburdens or equipment installed on top of the finished waterproofing system.

- ensure the membrane performs as it should.

- provide a suitable substrate for membrane application.

- Insulation overlay boards may be mechanically attached or adhered, depending upon the insulation type and the design requirements of the entire roof assembly.

Notes to Part 9

A-9.1.3.3. System Securement

- SBS-modified bituminous membranes are fabricated as rolled sheets and, when specified for use on roofs, are normally designed for application only on Flat or Low Slope structural roof decks and come in a variety of thicknesses and surface finishes. They may be reinforced with different materials (each reinforcement material exhibiting particular properties and offering different benefits), and may each be applied in one or more ways.

- Most SBS-modified bituminous membranes are designed as two separate plies – a base and cap membrane – which are heat-welded together as a 2-ply assembly. Some are self-adhered or adhered to each other and to a substrate with mop-applied hot bitumen or with an adhesive (see below). A third ply is occasionally part of the manufacturer's specified system and may be required or simply is prudent for additional waterproofing protection in certain circumstances.

- Common applications include:

- Mechanically fastened (where the base membrane is affixed to the roof deck with self-drilling screws and load-distributing plates; the cap membrane is then torch-applied or adhered to the base).

- Torch-applied (where torch heat brought to bear on the both the base and cap membranes liquefies the modified bitumen in the membrane so that it bonds with the substrate below).

- Adhered:

- Self-adhering (SA) (using a proprietary adhesive film bonded to the modified bitumen, SA membranes are often adhered with the help of a primer; occasionally, the base membrane is self-adhering, and the cap membrane is then torch-applied to the base).

- Cold-adhered (using bitumen-based or synthetic adhesive, this may sometimes be referred to as 'cold-applied’).

- Hot bitumen adhered (sometimes referred to as 'hot-mopped', 'hot-applied' or simply 'mopped', this application method applies to both the base and cap membranes, or may apply only to the base membrane; the cap, then, is torch-applied to the base membrane).

A-9.1.3.4. Membrane Protection

- Sunlight reflected from windows, doors, cladding and other reflective materials can elevate roof surface and sub-surface temperatures, which may shorten the life of a membrane and the roof system materials beneath it, and may cause irreparable damage. Roofs oriented to face south and southwest are particularly vulnerable to these effects, and sunlight reflected from metal can be more damaging than light reflected by glass.

- For more about this phenomenon, read "The Impact of Solar Reflectivity of Glazing Adjacent Roofs", published in the Summer 2021 issue of RoofingBC.

A-9.3.3.1. Self-adhered and Cold Adhesive-applied Membranes

- "Adhered" refers to a broad category of membranes that may be self-adhering, typically requiring a primer to enhance adhesion (refer to the manufacturer's published instructions), adhered with cold adhesives (synthetic or bitumen-based), or mop-applied with hot bitumen (bitumen that is melted in a kettle). Different requirements apply to each of these, depending on the membrane type, the method of application and the slope of the roof.

Notes to Part 10

A-10.1.3.1.(4) General Requirements, roof-wall connections

- Structural and roof system materials expand and contract as temperatures change, and this can be exacerbated by exposure to sun, followed by cool nights. When these materials or assemblies are allowed to expand and contract independently of adjacent materials or assemblies, little if any impact on the roof system is ever noticed; but when they are fastened or adhered to each other, as they are when the roof field assembly is bonded to adjoining wall assemblies with membrane flashing, membrane racking may occur (see Racking in the Glossary).Some membranes will easily handle movement, while others will not and will require special detailing to permit independent movement. To avoid racking, which may result in membrane cracking or splitting, consult the membrane manufacturer's literature on flashing these types of details.

A-10.1.3.1.(5) General Requirements, EIFS

- For best practices, refer to the EIFS Practices Manual downloadable from the EIFS Council of Canada and Technical Bulletin 1, V. 1.2, "EIFS Trim and Mouldings - Design and Installation" issued by the EIFS Council of Canada.

A-10.1.6.1. Expansion Joints

- Roof expansion joints, or movement joints, are designed to safely absorb thermal expansion and contraction of materials, or to absorb vibration. This is especially critical on large roof areas where the expansion and contraction rates of materials, such as insulation panels, can adversely affect membranes and induce racking; by dividing the roof into smaller area units, these effects can be ameliorated.

- Expansion joints also allow for movement caused by settlement and earthquakes.

A-10.1.6.2. Control Joints

- Control joints (sometimes referred to as roof dividers) are site-built but relatively uncommon for roofs with flexible membranes. They are designed to help control thermal expansion and contraction stresses in the roof system where no structural expansion joint has been provided in the building design, by dividing large roof areas into smaller ones. Control joints may be present on older roofs with built-up roof systems, and will have to be taken into consideration by the Design Authority; in some cases, control joints may be eliminated for replacement roofing. Still, control joints may be employed by the Design Authority to control expansion and contraction of any materials in the roof system, or for dividing existing roof areas for phased replacement roofing.

- Control joints may be employed to divide a large roof area into smaller roof areas, for the purpose of phasing replacement roofing.

A-10.3.7.2. Intersections with Water-Shedding Roofs

- The maximum water level is the point where water naturally spills off a roof (for example, through an overflow drain). When a roof is not constructed with overflows, the spill-over point will be the top of the lowest roof edge detail (typically a parapet (See Article 11.1.4.2.). Roof drains may be unmaintained and severe storms or freeze-thaw cycling during winter months may interfere with a roof's ability to drain. Therefore, the waterproofing of the roof (and also the load design) should allow for a worst case scenario in which the roof fills to its maximum capacity. Contemplating such a scenario should give the designer pause when considering low-clearance openings in walls (i.e., doors, windows, and ventilation grilles), which may serve as de facto 'overflows' when other drains are inoperable .

- The effects of weather cannot be overstated. While an absence of maintenance is often faulted for blocked roof drains and overflows, snow and ice can radically alter the drainage of a roof; in some instances, where freezing rain coats snow on the roof, the encrusted top surface of the snow forms a new plane of drainage. Seasonal phenomena like this affect every detail on a roof - penetrations, curbs, and perimeter membrane flashing. While RGC Standards publish minimum requirements for membrane flashing, those minimums do not contemplate every possible condition that might affect a building. It is therefore incumbent upon the Design Authority to specify membrane flashing heights for the expected service conditions of the roof, for its location (Ref. British Columbia Building Code, Div. A, Functional Statement 80).

Notes to Part 11

A-11.1.4.2. Scuppers and Overflows

- The primary function of an overflow is to keep a roof from collapsing when primary roof drains are plugged or cannot drain heavy rainfall. New and existing buildings should incorporate overflows to handle large rain events. Refer to the "British Columbia Building Code" and the "British Columbia Plumbing Code" for drain sizing and location requirements.

A-11.1.4.3. Membrane Gutters

- Gutters designed with downward-draining flanged drains need sufficient width to properly secure and seal the flange to the gutter membrane system. Gutters narrower than 300 mm compromise this critical detail, either by forcing the installer to trim the flange to fit the gutter width (which can compromise securement of the drain body), or by reducing the breadth of membrane needed to properly seal the drain flange to the gutter bottom. Gutters designed with cast-iron drains must be at least 100 mm (4") wider than the width of the drain body, to permit a sufficient membrane seal; more width is better, improving the effectiveness of the drain installation.

A-11.2.1.2. Roof Drains and Scuppers

- Roof drains are comprised mainly of two parts: a bowl or flange that is affixed to the roof deck with mechanical fasteners or a proprietary clamping mechanism; and an integral drain stem that connects the bowl or flange to the leader. Roof drains are sized according to the diameter of the drain stem. The appropriate size and number of roof drains for any given roof area is determined by the relevant building code in force (Ref. "British Columbia Plumbing Code", Division B, Article 2.4.10.4., "Hydraulic Loads from Roofs or Paved Surfaces").

- Roof drains can be further classified as internal or external. Internal roof drains are connected to leaders located and connected to a storm building drain or sewer inside the exterior surface of a building. Internal roof drains may be made of cast iron (secured to the roof assembly with clamps) or from copper or aluminum, fashioned from spun components that are welded together and incorporate a flange around the drain bowl.

- External roof drains direct storm water outside the exterior surface of a building. Scuppers and overflow drains are the common types of external roof drains, and may connect to leaders or simply drain freely. Any requirements for leaders and connections to leaders may be found in the applicable municipal and provincial building and plumbing codes (Ref. "British Columbia Building Code", Division B, Article 5.6.2.2., "Accumulation and Disposal").

Notes to Part 12

Notes to Part 13

Notes to Part 14

A-14.1. Design

- Membrane roof systems may be utilized for more than simple weather protection; they can be occupied by casual or regular users, for gardening, playing, lounging, or other leisure activities. Roofs that serve as amenity spaces require that the Design Authority pay particular attention to the system selection itself and, especially, to the protection of the roof membrane.

- A conventionally insulated system is not appropriate for all types of use or roof coverings. For example, the designed live loading for occupied spaces, or the weight of a roof covering, may require the Design Authority to specify particular materials, and consequently to design a roof as a protected roof system. Furthermore, some roof coverings require maintenance that may result in damage to conventionally insulated systems; protected roof system shield the sensitive membrane from this inevitability.

- A protected roof system (often referred to as an "inverted roof") offers the designer many benefits, including

- longer lasting membranes.

- capacity for heavier dead and live loads.

- only one control layer to seal and join with the rest of the building envelope.

- fewer waterproofing challenges around penetrations.

- the capacity for electronic leak detection (whether passive or monitored).

A-14.1.3.0. Filter Fabric

- Filter fabric is necessary to contain XPS insulation and thereby prevent ‘insulation stacking’ (displacement) when insulation boards become buoyant in water. The fabric also prevents "fines" from settling at the membrane level and filling the voids between insulation board joints.

A-14.1.3.10. Gravel

- Gravel used as a roof covering is different from its function as ballast on a protected roof system or modified protected roof system; gravel used as ballast is considered a means of securement (holding down the rest of the roof system) and is covered in Part 3, "Securing the Roof Assembly", and in Part 9.

A-14.1.3.11. Wearing Surfaces

- Inaccessible wearing surfaces such as concrete are permissible, but because the cost to remove them, in the event of a leak, is borne by the owner of the roof, specifying a scored slab may minimize destruction costs by isolating wearing surface removal and replacement to specific grids. Also, consider "Electronic Leak Detection" when specifying wearing surfaces like concrete; working in combination with a scored slab, ELD can minimize slab removal costs.

- Note that not all filter fabrics can successfully prevent the passage of concrete slurry. For this reason, the Design Authority should consult with the membrane manufacturer concerning a suitable filtering product.

A-14.1.3.13. Structures and Equipment

- Because roof membranes eventually require renewal (see Part 1 for available options), constructing heavy installation on a membrane poses challenges for the roofing contractor at renewal time (and leaks that occur beneath a heavy structure cannot be repaired without considerable expense by the owner). Therefore, consider specifying only relatively light superimposed loads for placement on the membrane, and consider structural supports for larger installations that, by their nature, cannot be moved to facilitate roof membrane renewal.

A-14.3.2.6. Vegetated Roof Systems

- Built-in-place vegetated roof systems often are constructed and maintained using sharp or pronged hand tools. To ensure the roof membrane is not damaged during installation or maintenance of the VRS, the Design Authority should consider adding additional penetration-resistant protection courses, including protection around all perimeters.

© RCABC 2024

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.