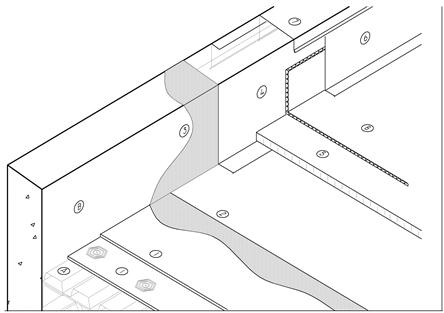

WP Details:F1.7.4 (Steel Deck - Substrate Overlay Board)

WP Details:F1.7.4 (Steel Deck - Substrate Overlay Board)

| RoofStar Guarantee Standards are blue-linked |

1 WORK INCLUDED

(1) Deck Overlay Substrate Boards: two layers of fibre-mat reinforced cement board, minimum thickness 9.5 mm (3/8"), conforming to ASTM C1325-04 or gypsum board with fibreglass facer and silicone treated core, minimum thickness 12 mm (1/2"), conforming to ASTM E 661

(2) Primary Waterproofing Membrane: Fully adhered to acceptable substrates.

(3) Membrane Primer or Adhesive: Proprietary primer or adhesive, application and quantities as directed by membrane manufacturers published application specifications.

(4) Membrane flashing (stripping): Carried up wall minimum 200 mm (8") above deck surface a minimum of 100mm (4") above top surface of waterproofing assembly. Typical low outside parapet wall depicted, membrane carried over top of wall and down exterior face minimum of 50mm (2").

(5) Insulation: Optional: Extruded, Expanded Polystyrene, Type 4, CAN/ULC-S701-97, compressive strength of 240 kpa (35 psi).

(6) Metal Base Flashing: Required on all waterproofing assemblies. Flashing lengths joined by use of S-locks or standing seam joints.

(7) Metal Base Flashing: Must overlap exterior wall finish. See 15.1 for RoofStar Guarantee Standards applicable to base metal flashing. Fasten with continuous concealed clip-type fasteners or cladding screws evenly spaced between seams. See 15.3 Attachment.

(8) Drainage Medium: Proprietary (purpose-made) drainage board designed to provide secondary drainage below poured concrete wearing slabs and unit masonry (pavers, brick or stone) set in mortar beds.

2 WORK BY OTHERS

(A) Acceptable Deck: Steel deck depicted.

(B) Wall Finish: Concrete depicted.

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

Back to Waterproofing Application