Asphalt Shingles - Cylindrical Penetration (Flashing, Storm Collar)

Asphalt Shingles - Cylindrical Penetration (Flashing, Storm Collar)

Revision as of 21:27, 2 February 2021 by James Klassen (talk | contribs)

| RoofStar Guarantee Standards are blue-linked |

Asphalt Shingle Details

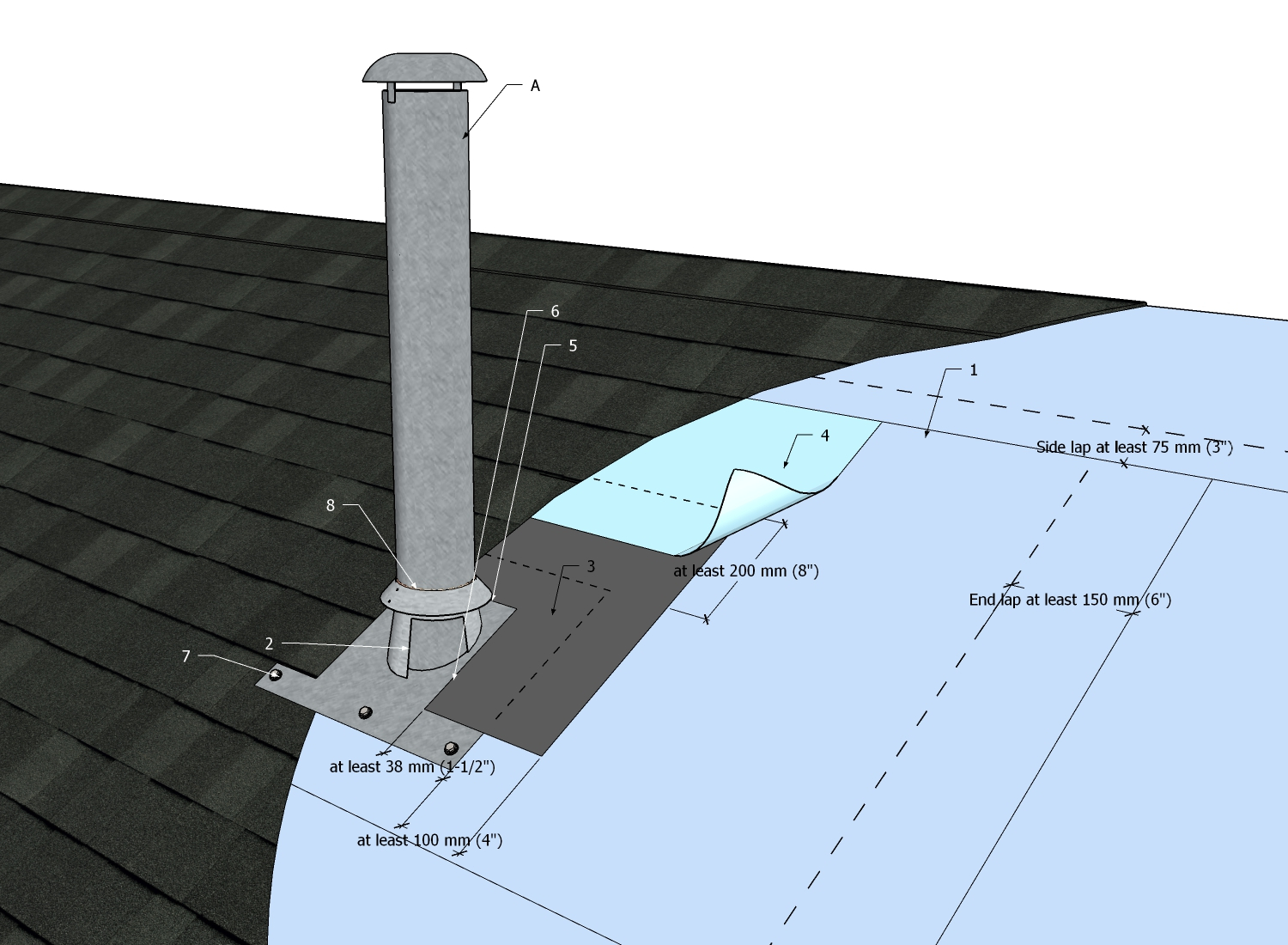

1 WORK INCLUDED

- (1) Underlayment

- Self-adhering or mechanically fastened, depending upon the designed slope (see 8.1.2 Design). Install “shingle-style” and overlap roll ends at least 150 mm (6”); side laps must be at least 75 mm (3”).

- (2) Penetration flashing

- Conforming to material standards in 11.2 Materials. Drawing shows cut-away, for illustrative purposes only.

- (3) Horseshoe patch

- Self-adhered membrane cut to fit penetration flashing flange and extend beyond flange edges as shown in drawing and required in 11.3.1 General.

- (4) Underlayment patch

- Overlaps the horseshoe patch and fits beneath the upper course of underlayment material.

- (5) Drainage path (top of penetration flashing)

- Minimum 12 mm (1/2”).

- (6) Drainage path (side of penetration flashing)

- Minimum 19 mm (3/4’).

- (7) Exposed fasteners

- Cladding fasteners with gasketed washers. See 11.3.1 General and 13.2.3 Fasteners.

- (8) Storm collar

- Required for pipe-type flashings (see 11.3.3 Penetrations and Vents). Caulked with an untooled bead of an acceptable sealant.

2 RELATED WORK BY OTHERS

- (A) Penetration

- (B-vent shown)

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

RoofStar Guarantee Standards for Asphalt Shingle Systems