Asphalt Shingles - Curb Flashing (Typical)

Asphalt Shingles - Curb Flashing (Typical)

Revision as of 14:39, 30 June 2022 by James Klassen (talk | contribs) (James Klassen moved page ASh 11.1.3 Curb Flashing (Typical) to Asphalt Shingles - Curb Flashing (Typical))

Division D - Construction Details

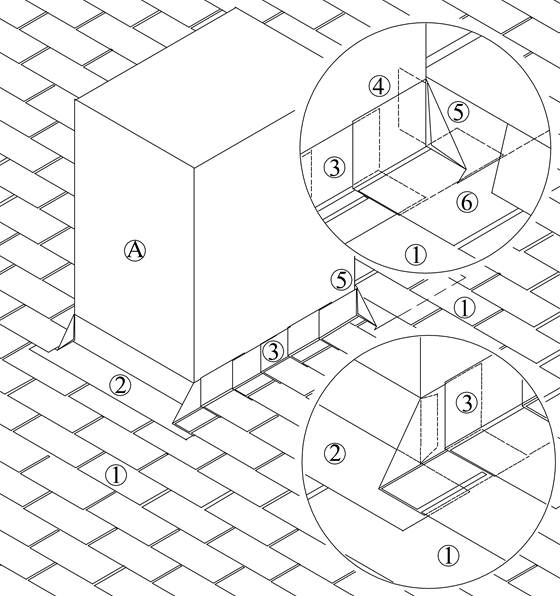

Asphalt Shingles | Curb Flashing (Typical) ( Article 12.3.2.4.)

| Notice to Reader | |

| Images used in a Construction Detail are representative and not prescriptive, and are not necessarily drawn to scale. They are intended to support the related Standard (Ref. Division A, Article 2.2.1.2.).

The reader may link to the related Article in the detail title, or link to the Standard as it relates to a specific element in the detail. All hyperlinks are displayed blue text. | |

Asphalt Shingle Details

1 WORK INCLUDED

- (1) Asphalt Shingles

- Installed to manufacturer’s published instructions and RoofStar Guarantee Standards.

- (2) Apron Flashing

- Extended a minimum 100mm (4") beyond corners, interwoven with shingles and step flashings.

- (3) Step Flashing

- Interwoven with each course of shingles, 75mm (3") head lap.

- (4) Final Step flashing

- Extended around corner of the upstand and under back pan flashing. The upstand fold can alternatively be turned outward under the back pan fold.

- (5) Backpan Flashing

- The back-pan is to be extended 100mm (4") beyond the corner and folded. Apply caulking at the transition corner of the final step flashing and back pan.

- (6) Capillary Section

- A capillary tab is to be extended off the end of the back pan to lead water around the corner.

- Proprietary soldered or welded diverter flashing may be used provided they conform to RoofStar Guarantee Standards.

NOTE: See the Standard for additional requirements.

Back to Asphalt Shingle System Details

© RCABC 2026

RoofStarTM is a registered Trademark of the RCABC.

No reproduction of this material, in whole or in part, is lawful without the expressed permission of the RCABC Guarantee Corp.