Difference between revisions of "ASM 10.4.3 Ridge (Vented)"

Difference between revisions of "ASM 10.4.3 Ridge (Vented)"

(→WORK INCLUDED) |

|||

| Line 7: | Line 7: | ||

;(7) [[RoofStar Guarantee Standards for ASM Roof Systems#ASMPANEL |'''Architectural Metal Roof Panel''']] : Turn up (bread panned) at termination and drag load fastened with compatible non-corrosive fasteners. | ;(7) [[RoofStar Guarantee Standards for ASM Roof Systems#ASMPANEL |'''Architectural Metal Roof Panel''']] : Turn up (bread panned) at termination and drag load fastened with compatible non-corrosive fasteners. | ||

;(4) [[RoofStar Guarantee Standards for ASM Roof Systems#ASMCLIP|'''Metal Panel Clip''']]: Installed to metal roof panel manufacturer's printed instructions. | ;(4) [[RoofStar Guarantee Standards for ASM Roof Systems#ASMCLIP|'''Metal Panel Clip''']]: Installed to metal roof panel manufacturer's printed instructions. | ||

| − | ;(5) ''''Z' | + | ;(5) [[RoofStar Guarantee Standards for ASM Roof Systems#ASMZ |''''Z' Closure''']]: Set in accepted caulking and secured with compatible non-corrosive flat head fasteners. |

;(6) '''Perforated Metal Screen''' | ;(6) '''Perforated Metal Screen''' | ||

;(7) '''Continuous Cleat''' | ;(7) '''Continuous Cleat''' | ||

;(8) '''Metal Cap Flashing''': Joints overlapped 100 mm (4") minimum, sealed with two rows of accepted caulking. Exposed edges must be turned under. | ;(8) '''Metal Cap Flashing''': Joints overlapped 100 mm (4") minimum, sealed with two rows of accepted caulking. Exposed edges must be turned under. | ||

| − | |||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

Revision as of 18:25, 10 August 2016

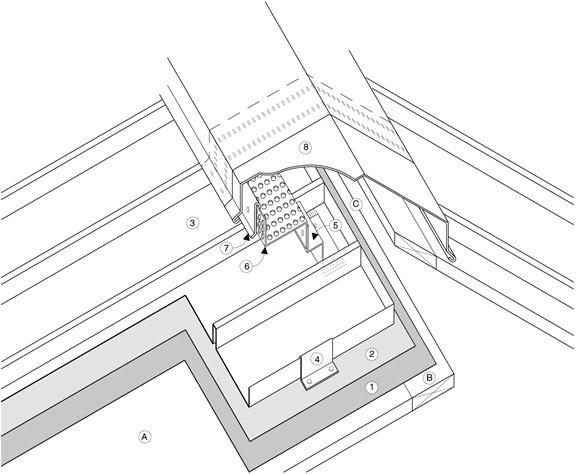

1 WORK INCLUDED

- (1) Underlayment

- The type of underlay required is determined by roof slope.

- (2) Slip Sheet

- Recommended over asphaltic underlays and / or as required by metal roof panel manufacturer.

- (7) Architectural Metal Roof Panel

- Turn up (bread panned) at termination and drag load fastened with compatible non-corrosive fasteners.

- (4) Metal Panel Clip

- Installed to metal roof panel manufacturer's printed instructions.

- (5) 'Z' Closure

- Set in accepted caulking and secured with compatible non-corrosive flat head fasteners.

- (6) Perforated Metal Screen

- (7) Continuous Cleat

- (8) Metal Cap Flashing

- Joints overlapped 100 mm (4") minimum, sealed with two rows of accepted caulking. Exposed edges must be turned under.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Wood Nailer

- (C) Air Space

- Determined by Design Authority.

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.