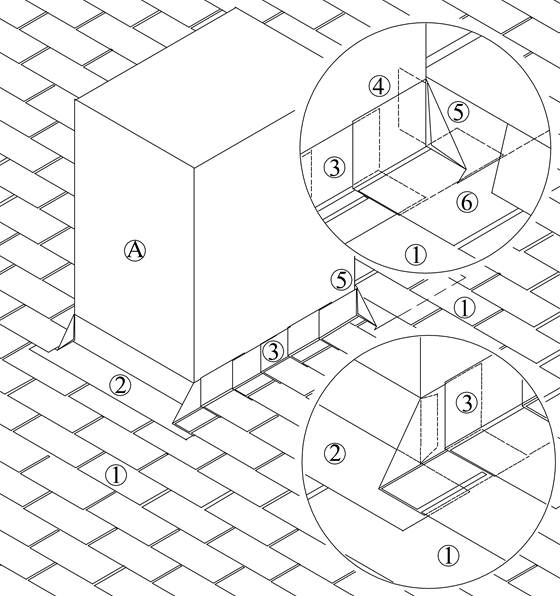

Asphalt Shingles - Curb Flashing (Typical)

Asphalt Shingles - Curb Flashing (Typical)

WORK INCLUDED

- (1) Asphalt Shingles

- Installed to manufacturer’s published instructions and RGC Guarantee Standards.

- (2) Apron Flashing

- Extended a minimum 100mm (4") beyond corners, interwoven with shingles and step flashings.

- (3) Step Flashing

- Interwoven with each course of shingles, 75mm (3") head lap.

- (4) Final Step flashing

- Extended around corner of the upstand and under back pan flashing. The upstand fold can alternatively be turned outward under the back pan fold.

- (5) Backpan Flashing

- The back-pan is to be extended 100mm (4") beyond the corner and folded. Apply caulking at the transition corner of the final step flashing and back pan.

- (6) Capillary Section

- A capillary tab is to be extended off the end of the back pan to lead water around the corner.

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

- Proprietary soldered or welded diverter flashing may be used provided they conform to RoofStar Guarantee Standards.

Back to Asphalt Shingle Application