Difference between revisions of "Draft CD 7"

Difference between revisions of "Draft CD 7"

| Line 3: | Line 3: | ||

|- | |- | ||

| style="color: black; background-color: #ffffcc; width: 100%;text-align:center" | Images used in a Construction Detail are representative and <u>not intended in their representation of an assembly to be prescriptive</u>. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the Standards, Guiding Principles and Recommendations of the '''RoofStar Guarantee Standards''' for a Waterproofing or Water-shedding System. Actual design with respect to dimensions, the selection of materials and their application remains the responsibility of the ''Design Authority''.<br><br>The full text of applicable '''''RoofStar Guarantee Standards''''' may be read by using the <span style="color:#6495ed">'''blue hyperlinks'''</span> | | style="color: black; background-color: #ffffcc; width: 100%;text-align:center" | Images used in a Construction Detail are representative and <u>not intended in their representation of an assembly to be prescriptive</u>. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the Standards, Guiding Principles and Recommendations of the '''RoofStar Guarantee Standards''' for a Waterproofing or Water-shedding System. Actual design with respect to dimensions, the selection of materials and their application remains the responsibility of the ''Design Authority''.<br><br>The full text of applicable '''''RoofStar Guarantee Standards''''' may be read by using the <span style="color:#6495ed">'''blue hyperlinks'''</span> | ||

| + | |} | ||

| + | {| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | ||

| + | | colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span style="color:#6495ed">'''blue-linked'''</span></big> | ||

|} | |} | ||

<div class="panel panel-success"> | <div class="panel panel-success"> | ||

| − | <div class="panel-heading"><big>''' | + | <div class="panel-heading"><big>'''ASM Details'''</big></div> |

<div class="panel-body"> | <div class="panel-body"> | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

<div style="text-align:center; vertical-align:center"> | <div style="text-align:center; vertical-align:center"> | ||

| − | [[File: | + | [[File:ASM 10.2.2 Roof-Headwall Connection (Vented).jpg|class=img-responsive | link=http://rpm.rcabc.org/images/5/5a/ASM_10.2.2_Roof-Headwall_Connection_%28Vented%29.jpg]] |

| − | |||

| − | |||

</div> | </div> | ||

| − | + | ::Click below for a printable version of this page (N/A) | |

| − | |||

| − | ::Click below for a printable version of this page | ||

<div style="width:150px; text-align: left;"> | <div style="width:150px; text-align: left;"> | ||

| − | :[[File:Pdf.png|100 px|link= | + | :[[File:Pdf.png|100 px|link=|'''Print Sheet''']] |

</div> | </div> | ||

| − | |||

| − | |||

</div><!-- COL-MD-6 --> | </div><!-- COL-MD-6 --> | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

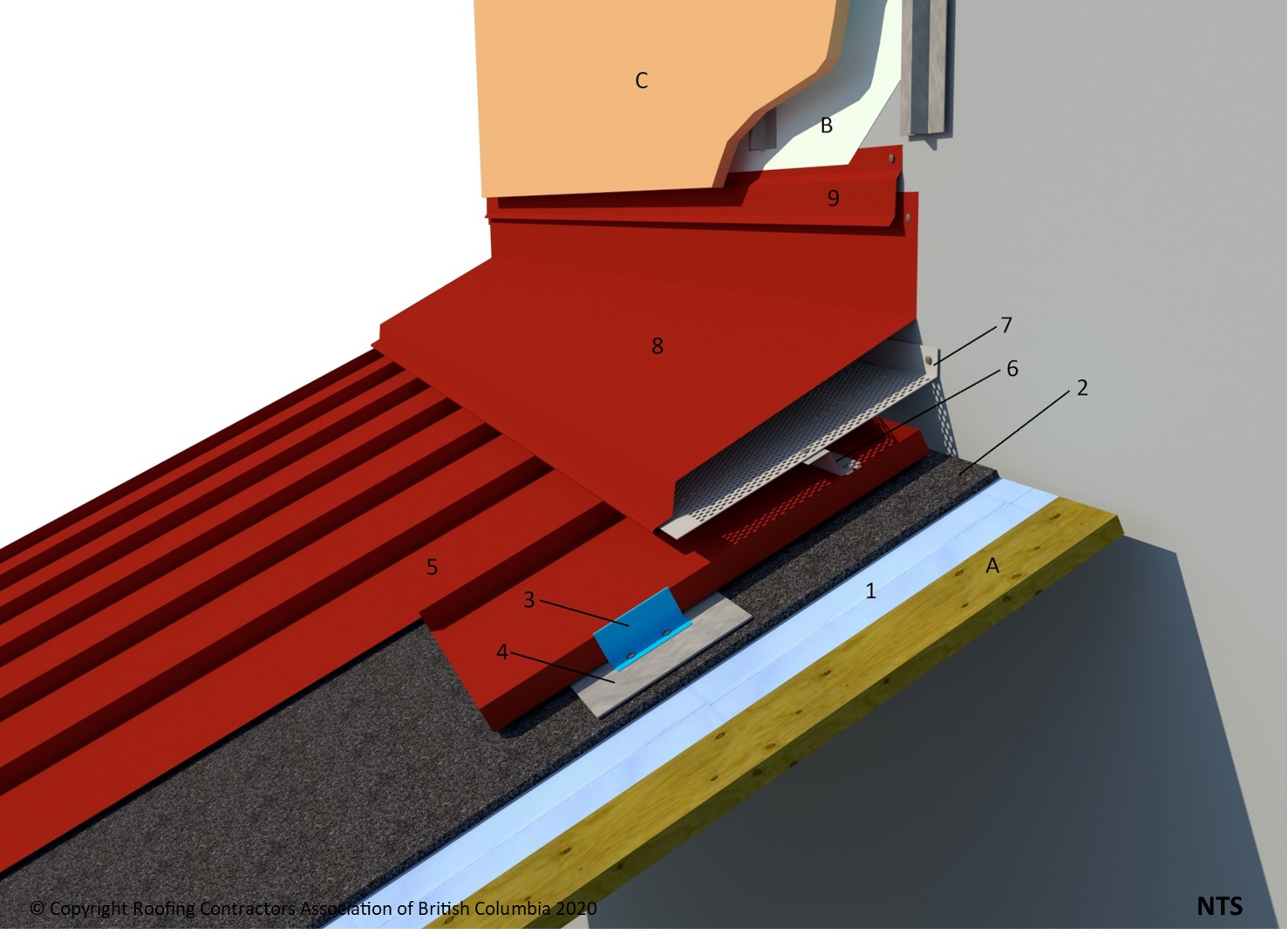

| − | ;(1) [[RoofStar Guarantee Standards for | + | ;(1) [[RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems#ASMUNDERLAYMENT|'''Underlayment''']]: Applicable for all Architectural Sheet Metal systems. For slopes less than 1:3, the entire roof slope must be covered with a <u>self-adhered</u> underlayment. |

| − | ;(2) [[RoofStar Guarantee Standards for | + | ;(2) [[RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems#ASMSEP-VENT|'''Ventilation material''']]: A ventilation space is required on slopes less than 1:3; entangled mesh (shown) may be used as void fill. The ventilation space facilitates drying as condensation forms on the underside of the metal panels. |

| − | ;(3) [[RoofStar Guarantee Standards for | + | ;(3) [[RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems#ASMCLIP|'''Metal Panel Clip''']]: Installed to metal roof panel manufacturer's printed instructions. |

| − | ;(4) | + | ;(4) Bearing plate: Used to support clips and distribute dead and live loads when direct contact with a solid substrate is not possible, or when entangled mesh is used within the ventilation space. |

| − | ;(5) [[RoofStar Guarantee Standards for | + | ;(5) [[RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems#ASMPANEL |'''Architectural metal roof panel''']] |

| − | ;(6) [[RoofStar Guarantee Standards for | + | ;(6) [[RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems#ASMZ |''''Z'-Closure''']]: Set in acceptable sealant and secured with compatible, non-corrosive, flat head fasteners. |

| − | ;( | + | ;(7) Ventilation screen: secured to the wall and to Z-girts to provide insect-resistant air flow around the roof-wall connection. Girts must be set in acceptable sealant and secured with compatible, non-corrosive, flat head fasteners. |

| − | ;( | + | ;(8) [[RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems#ASMSHEETMETAL |'''Sheet Metal Flashing''']]: Hooked to 'Z'-Closure and fastened to wall with non-corrosive, flat head fasteners 300 mm (12") o/c or preformed foam closures set in acceptable sealant with high domed gasketed cladding type screws at each standing rib. |

| + | ;(9) [[RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems#ASMCOUNTER |'''Metal Counter Flashing''']]: Must extend behind wall system and wall control layers. Stucco stops are not considered to be a counter flashing. | ||

<hr> | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[RoofStar Guarantee Standards for | + | ;(A) [[RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems#ASMDECK|'''Acceptable deck''']] |

| − | ;(B) ''' | + | ;(B) '''Wall control layers''': must be positively lapped with roof materials and flashings, to maintain continuity across systems. |

| + | ;(C) '''Wall cladding''': | ||

</div><!-- COL-6-MD --> | </div><!-- COL-6-MD --> | ||

</div><!-- PANEL BODY --> | </div><!-- PANEL BODY --> | ||

| Line 49: | Line 48: | ||

<hr> | <hr> | ||

| − | [[RoofStar Guarantee Standards for | + | [[RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems|<i class="fa fa-chevron-circle-right fa" ></i> RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems]] |

| − | |||

| − | |||

| − | [[Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] | + | [[Architectural Sheet Metal Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''ASM Construction Details'']] |

Revision as of 20:32, 2 October 2020

| Notice to Reader | |

| Images used in a Construction Detail are representative and not intended in their representation of an assembly to be prescriptive. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the Standards, Guiding Principles and Recommendations of the RoofStar Guarantee Standards for a Waterproofing or Water-shedding System. Actual design with respect to dimensions, the selection of materials and their application remains the responsibility of the Design Authority. The full text of applicable RoofStar Guarantee Standards may be read by using the blue hyperlinks | |

| RoofStar Guarantee Standards are blue-linked |

ASM Details

1 WORK INCLUDED

- (1) Underlayment

- Applicable for all Architectural Sheet Metal systems. For slopes less than 1:3, the entire roof slope must be covered with a self-adhered underlayment.

- (2) Ventilation material

- A ventilation space is required on slopes less than 1:3; entangled mesh (shown) may be used as void fill. The ventilation space facilitates drying as condensation forms on the underside of the metal panels.

- (3) Metal Panel Clip

- Installed to metal roof panel manufacturer's printed instructions.

- (4) Bearing plate

- Used to support clips and distribute dead and live loads when direct contact with a solid substrate is not possible, or when entangled mesh is used within the ventilation space.

- (5) Architectural metal roof panel

- (6) 'Z'-Closure

- Set in acceptable sealant and secured with compatible, non-corrosive, flat head fasteners.

- (7) Ventilation screen

- secured to the wall and to Z-girts to provide insect-resistant air flow around the roof-wall connection. Girts must be set in acceptable sealant and secured with compatible, non-corrosive, flat head fasteners.

- (8) Sheet Metal Flashing

- Hooked to 'Z'-Closure and fastened to wall with non-corrosive, flat head fasteners 300 mm (12") o/c or preformed foam closures set in acceptable sealant with high domed gasketed cladding type screws at each standing rib.

- (9) Metal Counter Flashing

- Must extend behind wall system and wall control layers. Stucco stops are not considered to be a counter flashing.

2 RELATED WORK BY OTHERS

- (A) Acceptable deck

- (B) Wall control layers

- must be positively lapped with roof materials and flashings, to maintain continuity across systems.

- (C) Wall cladding

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

RoofStar Guarantee Standards for Architectural Sheet Metal (ASM) Systems