Difference between revisions of "Draft CD 7"

Difference between revisions of "Draft CD 7"

(Created page with "{| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span sty...") |

|||

| Line 1: | Line 1: | ||

{| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | {| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | ||

| − | | colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span style="color:#6495ed">'''blue-linked'''</span | + | | colspan="2" | <big>'''''Notice to Reader'''''</big> |

| + | |- | ||

| + | | style="color: black; background-color: #ffffcc; width: 100%;text-align:center" | Images used in a Construction Detail are representative and <u>not intended in their representation of an assembly to be prescriptive</u>. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the Standards, Guiding Principles and Recommendations of the '''RoofStar Guarantee Standards''' for a Waterproofing or Water-shedding System. Actual design with respect to dimensions, the selection of materials and their application remains the responsibility of the ''Design Authority''.<br><br>'''''RoofStar Guarantee Standards''''' are <span style="color:#6495ed">'''blue-linked'''</span> | ||

|} | |} | ||

<div class="panel panel-success"> | <div class="panel panel-success"> | ||

| Line 25: | Line 27: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

| − | ;(1) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(1) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSAIRVAPOUR|'''Air or Vapour Control Layer''']]: Installed following the requirements of '''Part 6''' in this Standard. Tie in the control layers with membranes installed by other trades, to preserve continuity of the building enclosure ('''1a'''). |

| − | ;(2) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(2) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSINSULATIONAPPLICATION|'''Insulation''']]: Installed in staggered and offset layers (not illustrated), and secured in accordance with the design of the system, which is based on the British Columbia Building Code, Part 4 and Part 5, and on '''Part 3''' of the '''''RoofStar Guarantee Standards''''' for the membrane system type. |

| − | ;(3) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(3) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSINSULATIONOVERLAY|'''Insulation Overlay''']]: Subject to the requirements of '''Part 8''' in the '''''RoofStar Guarantee Standards''''' for the membrane system type. |

| − | ;(4) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(4) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSMEMBRANES|'''Base Membrane (field)''']]: Mechanically attached, torch-applied, adhered or self-adhered. See Tables '''9.1''' and '''9.2''' for acceptable membrane types and securement options. See '''9.3''' for application requirements. |

| − | ;(5) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(5) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSPERIMETERS|'''Base Membrane (flashing)''']]: Carried vertically up a wall or parapet at least 200 mm (8”), and onto the roof field at least 100 mm (4”) (greater if required by the membrane manufacturer). Prime substrate, as required by the membrane manufacturer. |

| − | ;(6) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(6) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSMEMBRANES|'''Cap Membrane (field)''']]: Granule-surfaced membrane. See Tables '''9.1''' and '''9.2''' for acceptable cap membrane types and their securement options. See '''9.3''' for application requirements. |

| − | ;(7) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(7) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSPERIMETERS|'''Cap Membrane (flashing)''']]: Extended vertically past the termination of the base membrane flashing, to provide a positive seal at the top edge. |

| − | ;(8) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(8) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSMETALCANT|'''Metal Cant Flashing''']]: Secure metal flashings with appropriate fasteners set at least 87 mm (3 ½”) above the finished roof surface. Alternatively, secure flashing from the outside face (illustrated). See '''13.3.7 Cant Edges''' for metal flashing securement requirements. |

<hr> | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(A) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSDECKS|'''Acceptable Deck''']] |

| − | ;(B) '''Fascia''' | + | ;(B) '''Cant and Fascia Woodwork''' |

| − | |||

</div><!-- COL-6-MD --> | </div><!-- COL-6-MD --> | ||

</div><!-- PANEL BODY --> | </div><!-- PANEL BODY --> | ||

| Line 45: | Line 46: | ||

'''NOTE''': Refer to '''''RoofStar Guarantee Standards''''' for additional requirements. | '''NOTE''': Refer to '''''RoofStar Guarantee Standards''''' for additional requirements. | ||

| − | |||

<hr> | <hr> | ||

| − | |||

[[RoofStar Guarantee Standards for SBS Modified Bitumen Roof Assemblies |<i class="fa fa-chevron-circle-left fa" ></i> Back to ''RoofStar Guarantee Standards for SBS Modified Bitumen Roof Assemblies'']] | [[RoofStar Guarantee Standards for SBS Modified Bitumen Roof Assemblies |<i class="fa fa-chevron-circle-left fa" ></i> Back to ''RoofStar Guarantee Standards for SBS Modified Bitumen Roof Assemblies'']] | ||

Revision as of 21:11, 11 February 2020

| Notice to Reader | |

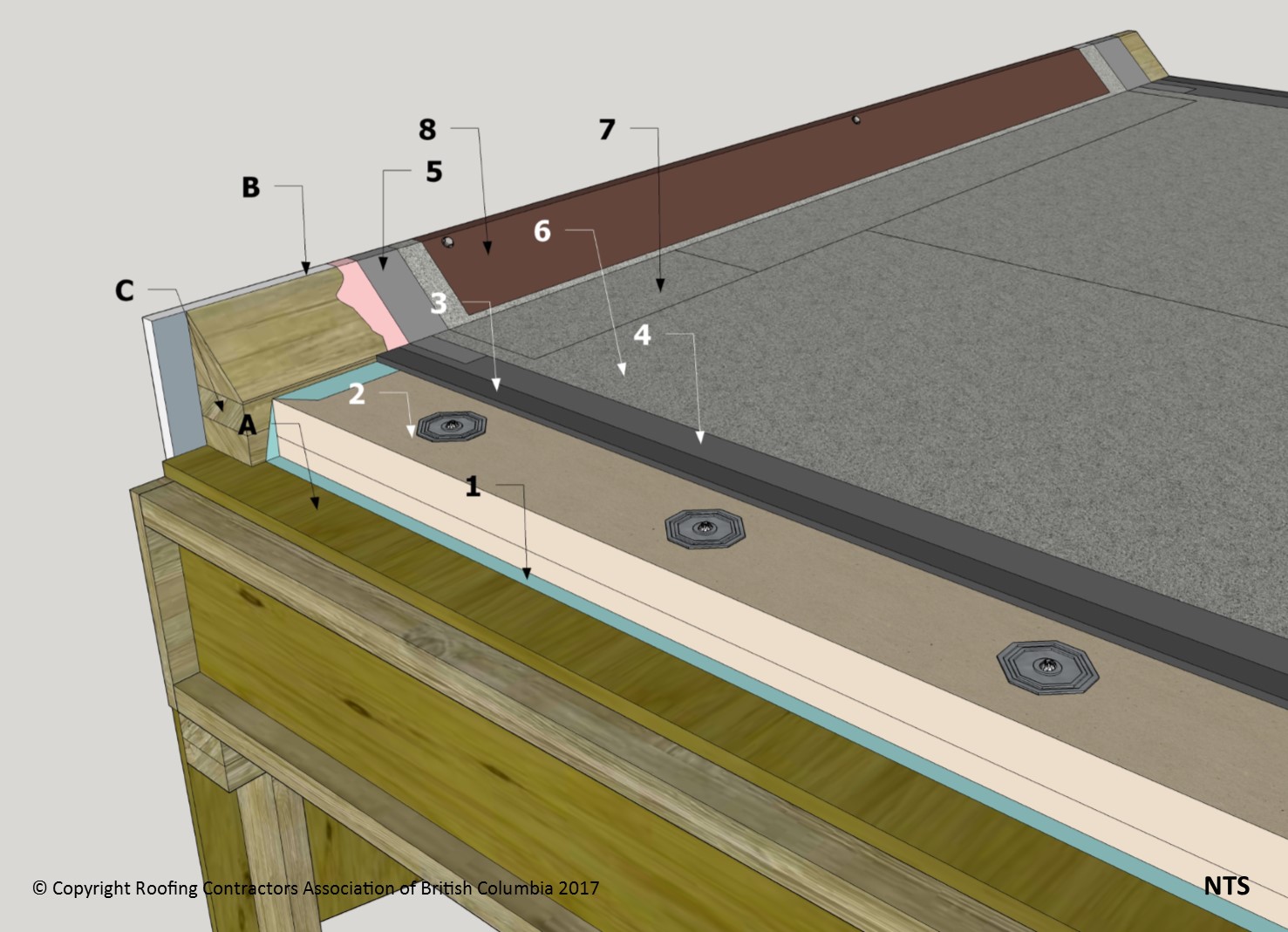

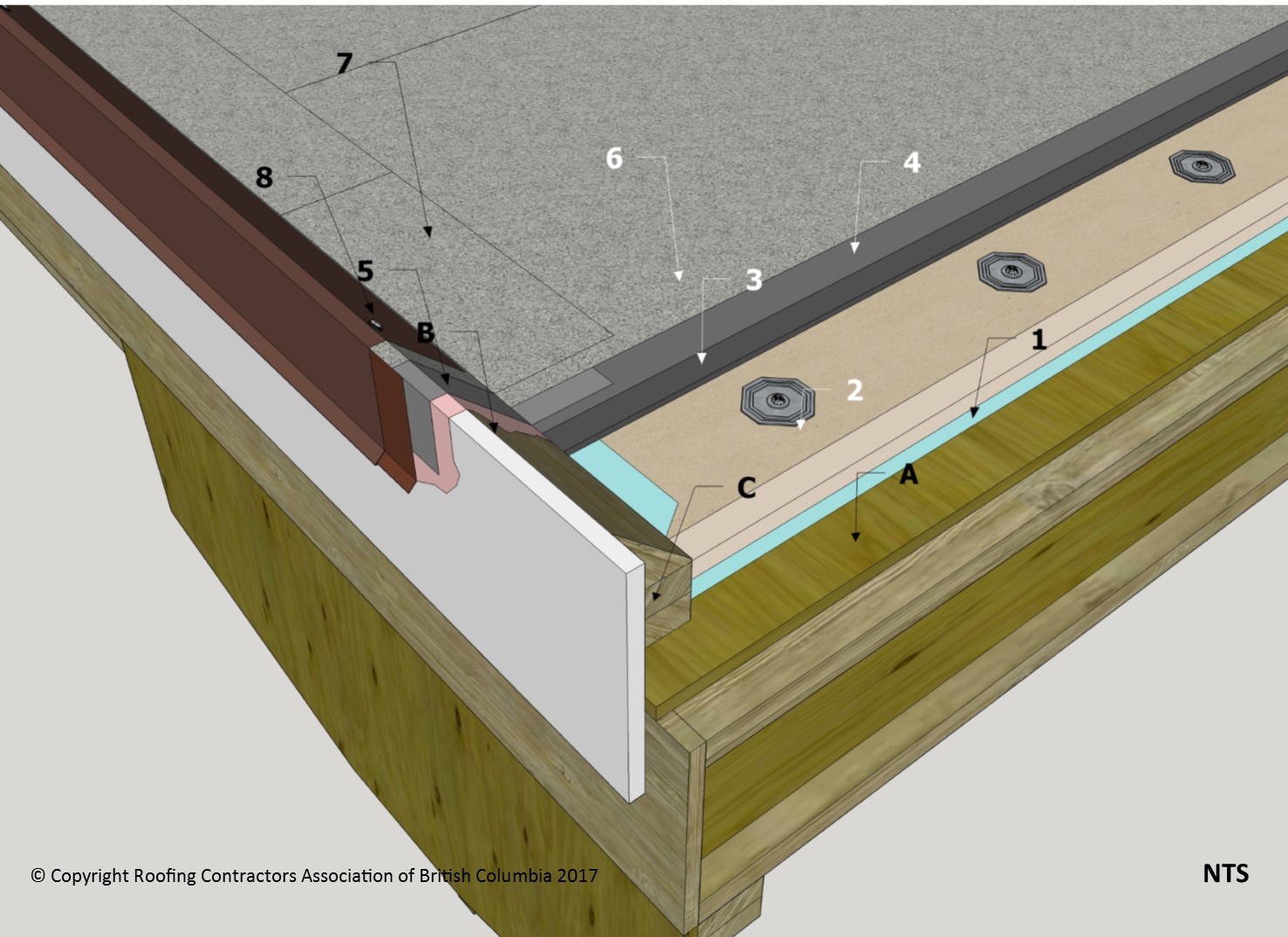

| Images used in a Construction Detail are representative and not intended in their representation of an assembly to be prescriptive. Nor are they necessarily drawn to scale. Rather, they are provided to visually convey the Standards, Guiding Principles and Recommendations of the RoofStar Guarantee Standards for a Waterproofing or Water-shedding System. Actual design with respect to dimensions, the selection of materials and their application remains the responsibility of the Design Authority. RoofStar Guarantee Standards are blue-linked | |

SBS Details

1 WORK INCLUDED

- (1) Air or Vapour Control Layer

- Installed following the requirements of Part 6 in this Standard. Tie in the control layers with membranes installed by other trades, to preserve continuity of the building enclosure (1a).

- (2) Insulation

- Installed in staggered and offset layers (not illustrated), and secured in accordance with the design of the system, which is based on the British Columbia Building Code, Part 4 and Part 5, and on Part 3 of the RoofStar Guarantee Standards for the membrane system type.

- (3) Insulation Overlay

- Subject to the requirements of Part 8 in the RoofStar Guarantee Standards for the membrane system type.

- (4) Base Membrane (field)

- Mechanically attached, torch-applied, adhered or self-adhered. See Tables 9.1 and 9.2 for acceptable membrane types and securement options. See 9.3 for application requirements.

- (5) Base Membrane (flashing)

- Carried vertically up a wall or parapet at least 200 mm (8”), and onto the roof field at least 100 mm (4”) (greater if required by the membrane manufacturer). Prime substrate, as required by the membrane manufacturer.

- (6) Cap Membrane (field)

- Granule-surfaced membrane. See Tables 9.1 and 9.2 for acceptable cap membrane types and their securement options. See 9.3 for application requirements.

- (7) Cap Membrane (flashing)

- Extended vertically past the termination of the base membrane flashing, to provide a positive seal at the top edge.

- (8) Metal Cant Flashing

- Secure metal flashings with appropriate fasteners set at least 87 mm (3 ½”) above the finished roof surface. Alternatively, secure flashing from the outside face (illustrated). See 13.3.7 Cant Edges for metal flashing securement requirements.

2 RELATED WORK BY OTHERS

- (A) Acceptable Deck

- (B) Cant and Fascia Woodwork

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

Back to RoofStar Guarantee Standards for SBS Modified Bitumen Roof Assemblies