Difference between revisions of "Draft CD 9"

Difference between revisions of "Draft CD 9"

(Created page with "{| class="wikitable" | style="color: black; background-color: orange; width: 100%;text-align:center" | colspan="2" | <big>'''''RoofStar Guarantee Standards''''' are <span sty...") |

|||

| Line 7: | Line 7: | ||

<div class="col-md-6"> | <div class="col-md-6"> | ||

<div style="text-align:center; vertical-align:center"> | <div style="text-align:center; vertical-align:center"> | ||

| − | [[File: | + | [[File:SBS 11.3.3.3-2 2-Part Cable 1.jpg|class=img-responsive | link=http://rpm.rcabc.org/images/8/82/SBS_11.3.3.3-2_2-Part_Cable_1.jpg]] |

| + | <br> | ||

| + | <div class="col-md-8"> | ||

| + | [[File:SBS 11.3.3.3-2 2-Part Cable 2.jpg|class=img-responsive | link=http://rpm.rcabc.org/images/8/89/SBS_11.3.3.3-2_2-Part_Cable_2.jpg]] | ||

| + | </div> | ||

</div> | </div> | ||

| − | + | <div class="col-md-6"> | |

| − | |||

::Click below for a printable version of this page. | ::Click below for a printable version of this page. | ||

<div style="width:150px; text-align: left;"> | <div style="width:150px; text-align: left;"> | ||

| − | :[[File:Pdf.png|100 px|link= | + | :[[File:Pdf.png|100 px|link=|'''Print Sheet''']] |

| + | </div> | ||

</div> | </div> | ||

| − | |||

</div><!-- COL-MD-6 --> | </div><!-- COL-MD-6 --> | ||

| − | |||

<div class="col-md-6"> | <div class="col-md-6"> | ||

=== WORK INCLUDED === | === WORK INCLUDED === | ||

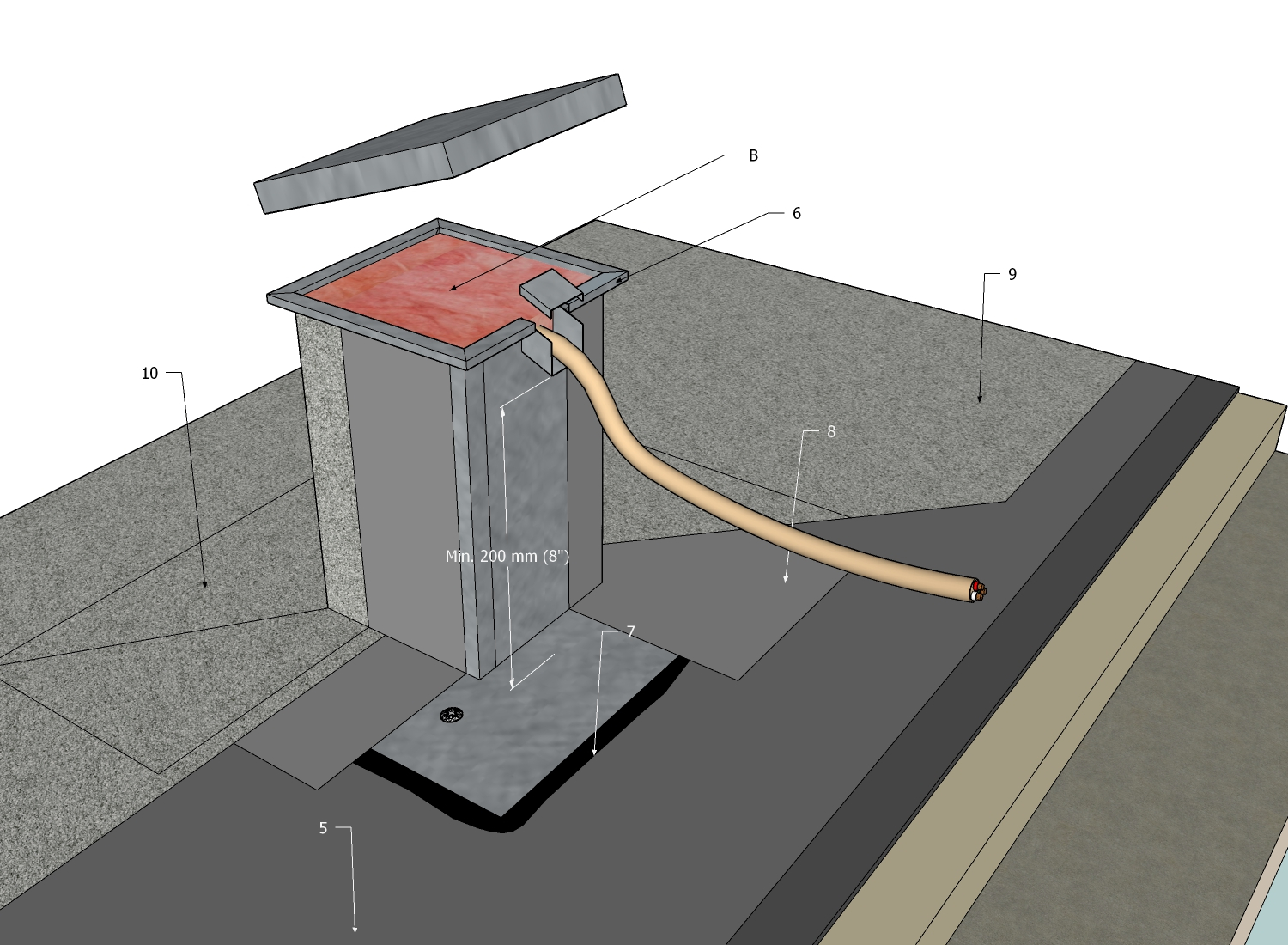

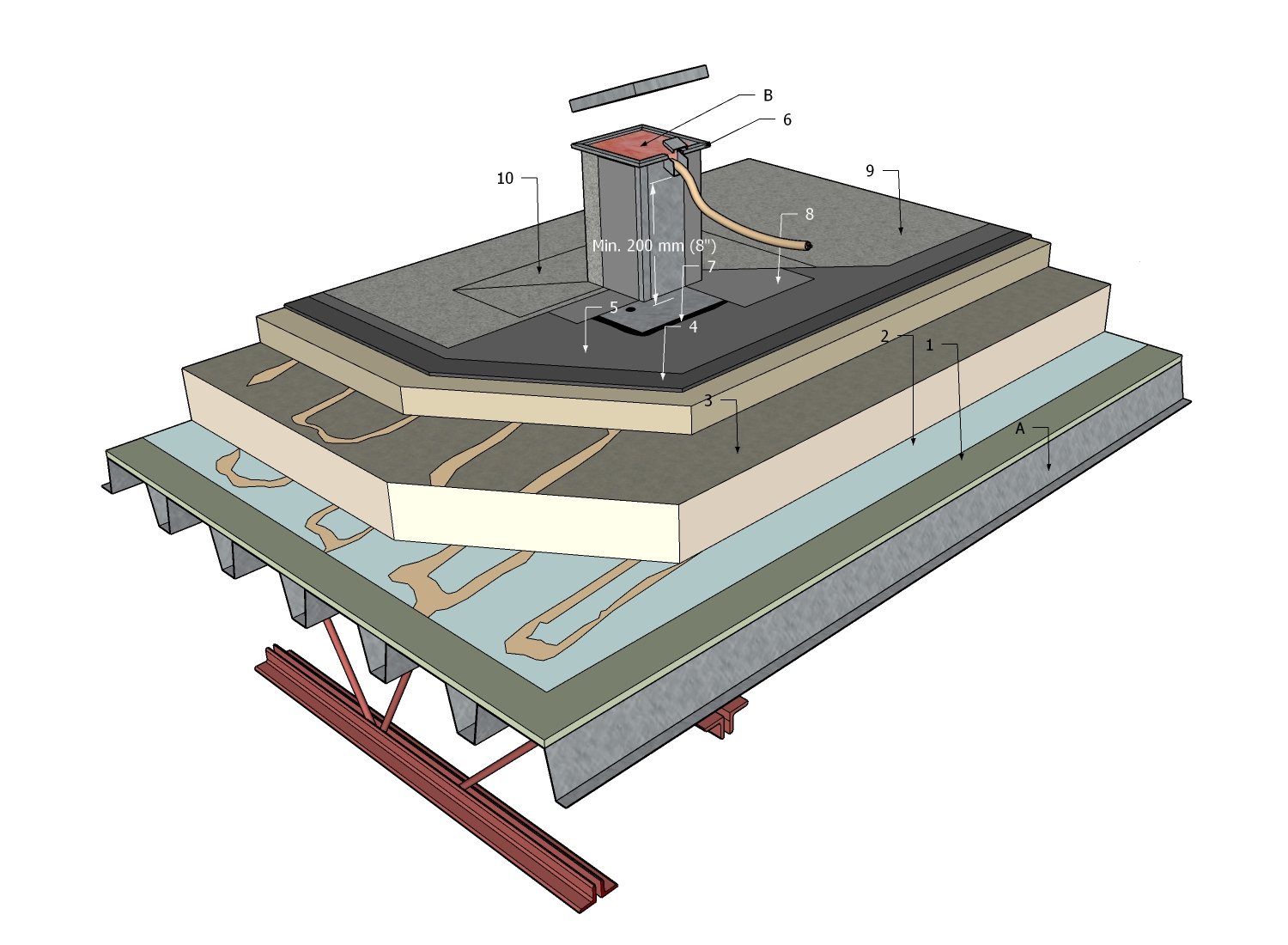

| − | ;(1) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(1) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSDECKWALLOVERLAY|'''Supporting Deck Overlay''']]: Optional, depending upon deck condition and roof system requirements. |

| − | ;(2) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(2) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSAIRVAPOUR|'''Air or Vapour Control Layer''']]: Installed following the requirements of '''Part 6''' in this Standard. Tie in the control layers with membranes installed by other trades, to preserve continuity of the building enclosure ('''2a'''). |

| − | ;(3) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(3) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSINSULATIONAPPLICATION|'''Insulation''']]: Installed in staggered and offset layers, and secured in accordance with the design of the system, which is based on the ''British Columbia Building Code'', Part 4 and Part 5, and on '''Part 3''' of the '''''RoofStar Guarantee Standards''''' for the membrane system type. |

| − | ;(4) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(4) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSINSULATIONOVERLAY|'''Insulation Overlay''']]: Subject to the requirements of '''Part 8''' in the '''''RoofStar Guarantee Standards''''' for the membrane system type. |

| − | ;(5) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(5) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSMEMBRANES|'''Field Membrane (field)''']]: Mechanically attached, torch-applied, adhered (shown) or self-adhered. See Tables '''9.1''' and '''9.2''' for acceptable membrane types and securement options. See '''9.3''' for application requirements. |

| − | ;( | + | ;(6) Two-part Penetration Cable Flashing: May be proprietary or shop-fabricated from galvanized sheet metal, consisting of two parts that are riveted together in the field, secured to the roof assembly and then ‘stripped’ into the field membrane to waterproof the flashing. This type of flashing may be adapted in its design to accommodate a pipe that turns horizontally to the roof field plane. The exit point for the penetration must be shielded with a hood and sloped downward to shed water. Secure separate lid with screw-type fasteners. |

| − | ;( | + | |

| − | ;( | + | :See '''11.2.3 Curbs and Penetration Flashings''' for fabrication standards. |

| + | ;(7) Mastic: Applied to area receiving metal penetration flashing. See '''11.3.3.1''' ('''12''')('''1'''). | ||

| + | ;(8) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSTARGET|'''Base Membrane Flashing (target patch)''']]: Cut from a single piece of self-adhering or torch-applied base membrane material, it is fashioned with a hole to fit around the penetration flashing and is sealed to the flashing and the roof field. The target patch must cover the flashing flange and extend beyond the edge of the flange, onto the field base membrane, by at least 100 mm (4”). See '''11.3.3.1''' ('''12''') for all applicable standards. | ||

| + | ;(9) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSMEMBRANES|'''Cap Membrane (field)''']]: Granule-surfaced membrane. See Tables '''9.1''' and '''9.2''' for acceptable cap membrane types and their securement options. See '''9.3''' for application requirements. | ||

| + | ;(10) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSPERIMETERS|'''Cap Membrane (flashing)''']]: Granule-surfaced membrane, installed following the standards published in '''Part 11'''. | ||

<hr> | <hr> | ||

=== RELATED WORK BY OTHERS === | === RELATED WORK BY OTHERS === | ||

| − | ;(A) [[RoofStar Guarantee Standards for SBS Modified Bitumen | + | ;(A) [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems#SBSDECKS|'''Acceptable Supporting Deck Structure''']] |

| − | ;(B) | + | ;(B) Fibreglass insulation: Cavity fill, to inhibit condensation inside the flashing. |

| − | + | ||

</div><!-- COL-6-MD --> | </div><!-- COL-6-MD --> | ||

</div><!-- PANEL BODY --> | </div><!-- PANEL BODY --> | ||

| Line 43: | Line 49: | ||

'''NOTE''': Refer to '''''RoofStar Guarantee Standards''''' for additional requirements. | '''NOTE''': Refer to '''''RoofStar Guarantee Standards''''' for additional requirements. | ||

| − | |||

<hr> | <hr> | ||

| − | + | [[RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems'']] | |

| − | [[RoofStar Guarantee Standards for SBS Modified Bitumen | ||

[[SBS Modified Bitumen Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''SBS Modified Bitumen Construction Details'']] | [[SBS Modified Bitumen Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''SBS Modified Bitumen Construction Details'']] | ||

[[Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] | [[Construction Details|<i class="fa fa-chevron-circle-left fa" ></i> Back to ''Construction Details'']] | ||

Revision as of 22:06, 11 February 2020

| RoofStar Guarantee Standards are blue-linked |

SBS Details

1 WORK INCLUDED

- (1) Supporting Deck Overlay

- Optional, depending upon deck condition and roof system requirements.

- (2) Air or Vapour Control Layer

- Installed following the requirements of Part 6 in this Standard. Tie in the control layers with membranes installed by other trades, to preserve continuity of the building enclosure (2a).

- (3) Insulation

- Installed in staggered and offset layers, and secured in accordance with the design of the system, which is based on the British Columbia Building Code, Part 4 and Part 5, and on Part 3 of the RoofStar Guarantee Standards for the membrane system type.

- (4) Insulation Overlay

- Subject to the requirements of Part 8 in the RoofStar Guarantee Standards for the membrane system type.

- (5) Field Membrane (field)

- Mechanically attached, torch-applied, adhered (shown) or self-adhered. See Tables 9.1 and 9.2 for acceptable membrane types and securement options. See 9.3 for application requirements.

- (6) Two-part Penetration Cable Flashing

- May be proprietary or shop-fabricated from galvanized sheet metal, consisting of two parts that are riveted together in the field, secured to the roof assembly and then ‘stripped’ into the field membrane to waterproof the flashing. This type of flashing may be adapted in its design to accommodate a pipe that turns horizontally to the roof field plane. The exit point for the penetration must be shielded with a hood and sloped downward to shed water. Secure separate lid with screw-type fasteners.

- See 11.2.3 Curbs and Penetration Flashings for fabrication standards.

- (7) Mastic

- Applied to area receiving metal penetration flashing. See 11.3.3.1 (12)(1).

- (8) Base Membrane Flashing (target patch)

- Cut from a single piece of self-adhering or torch-applied base membrane material, it is fashioned with a hole to fit around the penetration flashing and is sealed to the flashing and the roof field. The target patch must cover the flashing flange and extend beyond the edge of the flange, onto the field base membrane, by at least 100 mm (4”). See 11.3.3.1 (12) for all applicable standards.

- (9) Cap Membrane (field)

- Granule-surfaced membrane. See Tables 9.1 and 9.2 for acceptable cap membrane types and their securement options. See 9.3 for application requirements.

- (10) Cap Membrane (flashing)

- Granule-surfaced membrane, installed following the standards published in Part 11.

2 RELATED WORK BY OTHERS

- (A) Acceptable Supporting Deck Structure

- (B) Fibreglass insulation

- Cavity fill, to inhibit condensation inside the flashing.

NOTE: Refer to RoofStar Guarantee Standards for additional requirements.

Back to RoofStar Guarantee Standards for SBS Modified Bitumen Membrane Systems